An injection molding machine has various features and components that play a key role in the manufacturing of plastic parts. One such essential component of the injection molding machine is the valve gate.

The valve gate injection molding is an efficient technique, especially for large-volume production runs. Valve gates are a type of hot runner gates that are designed to include a unique gate pin i.e. the valve. The primary function of the valve gate is to control the plastic flow into the mold. In this article, we discuss valve gating systems, their advantages, and their applications in detail.

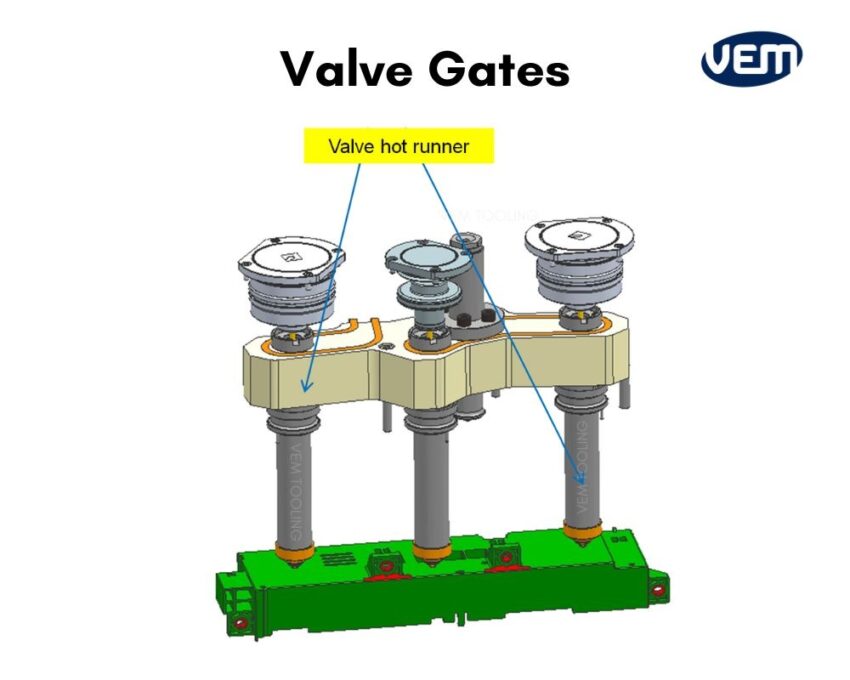

Valve gates are particularly used in hot runner systems. The primary purpose is to control the melt flow of the plastic into the mold. This is managed by controlling the shut-off time to prevent the collision of two flow fronts in the middle.

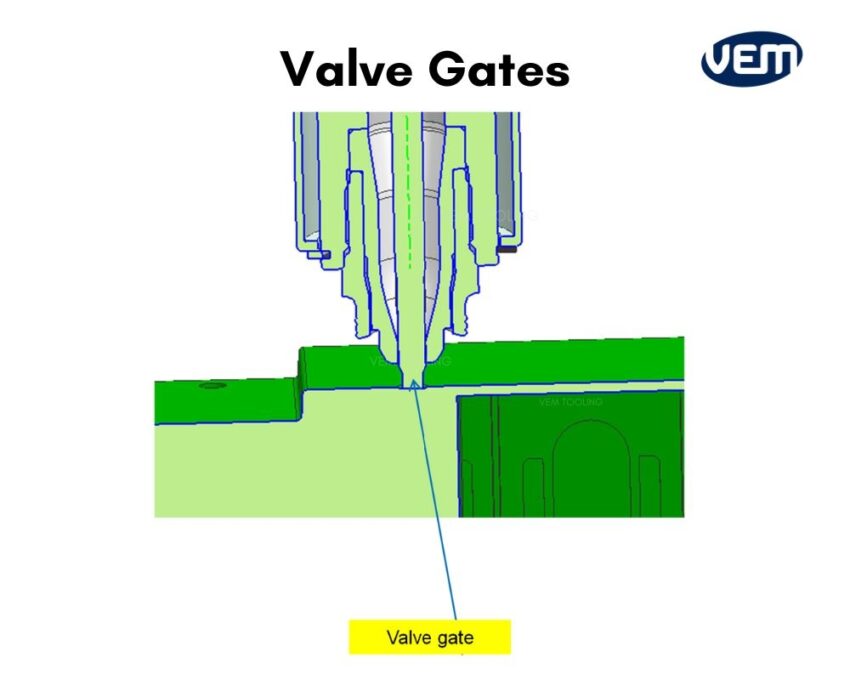

In this technique, a valve gate nozzle uses a valve stem to seal the gate. This is achieved via a mechanical force, where the valve stem slides forward and seals the gate orifice.

The valve gate system functions by using mechanical shut-off pins to regulate the flow of plastic into the mold cavity. This further enables the hot runner nozzle to open and close at the tip.

During the mold opening and part ejection, the valve stem remains closed thereby eliminating melt decompression of thermal gated systems. This is because the seal stays robust when the manifold of the hot runner system is under pressure. Melt decompression often leads to splay and other aesthetic flaws.

Since valve gates are difficult to modify, they are more effective than any other types of gates. In this system, the valve gate shuts off the exit and prevents the plastic from flowing out, thus, a valve gate is consistently reliable. You should note that as the valve stem protrudes through the gate, it may create a slight depression in the gate’s center.

Inadequate or incorrect gating can lead to a variety of issues thus, it is crucial to choose the correct gate for the mold design as well as the injection molding process.

The type of gate, its placement, and quantity can influence the cycle time, and affect the aesthetics, or the structural integrity of the parts produced during the injection molding processing. We have enlisted some critical aspects that must be considered:

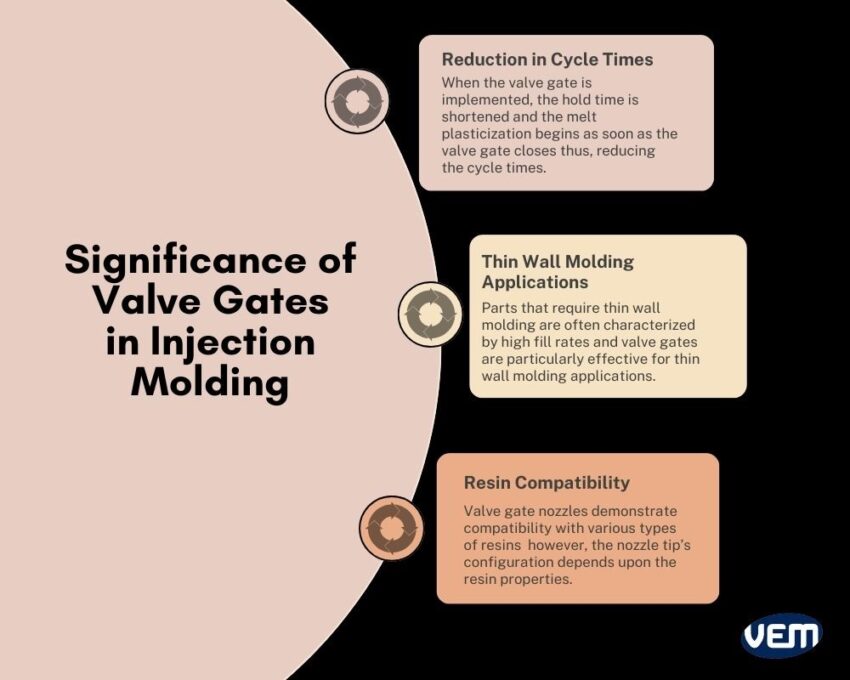

Valve gates are particularly effective in an automated manufacturing setup. Let’s take a look at some of the most significant aspects:

When the valve gate is implemented, the hold time is shortened and the melt plasticization begins as soon as the valve gate closes thus, reducing the cycle times. This also contributes to a reduced shear rate in the gate area thereby reducing the shear heating of the melt, and thus, lowering the part’s cooling time.

The cycle time is also reduced as these types of molds do not require a sufficiently frozen gate which is a requirement of thermally gated molds. In the case of thermally gated molds, the gate needs to be sufficiently frozen before hold pressure is released and screw recovery begins. This particular difference can cut down the cycle time by several seconds.

Valve gates are particularly effective for thin wall molding applications. Parts that require thin wall molding are often characterized by high fill rates, and subjected to high pressures, and rapid cooling. The mold cavity is also filled in rather quickly i.e. within 0.5 seconds or less so that the mold is filled in before the frozen layer solidifies.

Since valve gates demonstrate wide gates and a lack of flow constraints, fast-filling of the mold is possible.

Valve gate nozzles demonstrate compatibility with various types of resins however, the configuration of the nozzle tip is largely dependent upon the resin properties.

If the resins are amorphous, then the gate location should be thermally isolated from the nozzle and the nozzle tip to avoid heat transmission which can otherwise cause deformation in the gate area by delaying solidification. A valve gate nozzle intended for semi-crystalline and high-temperature amorphous resins must transfer heat to the gate seal-off area to ensure that the resin is molten. This is accomplished through a nozzle tip that’s integrated with a seal that further extends to the molding surface.

Sequential valve gate controllers are a popular technique used in the valve gate system. Let’s understand this technology further:

The sequential valve gate is a standard technique that fills the mold quickly. In this system, the fill valves of the mold are filled from the center. The sequential fill valve-controlled system uniformly distributes the molten resin into the cavity.

Sequential valve gate controllers are systems designed to open a group of gates independently of each other. Typically, there are multiple distinct gates in the valve gate system and they can either be controlled all together or they can open independently of one another. In the former, only one valve gate controller is required to control all the valve gates whereas, in the latter, a sequential valve gate is required to control the gates independently of one another.

Sequential valve gate controller systems demonstrate higher flexibility, increase production, lower costs, and reduce cycle times. It also improves dimensional stability by preventing gas bubbles.

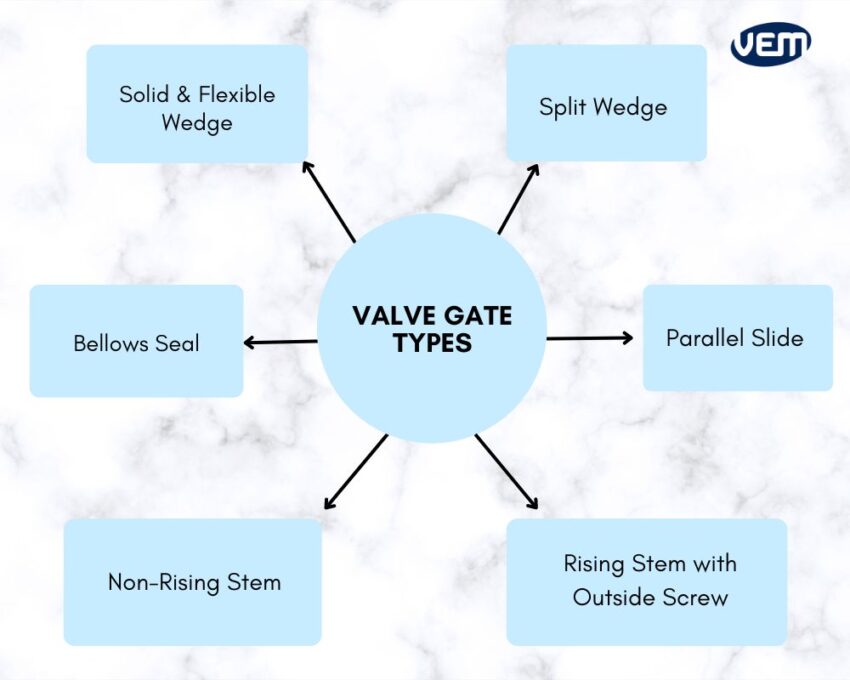

Let’s understand the various types of valve gates and how they can be applied:

This type of gate valve has a solid disk attached to the stem which moves up and down to open and close the valve. Since they are extremely durable, they can be used for high-pressure applications.

Solid wedge gate valves are extremely efficient as they are less likely to leak than other types of gate valves. However, you should note that they are also more difficult to operate than other valves as they require more torque to open and close.

This type of gate valve has a disk connected to the stem by two hinges which helps the disk to move up, down, and side-to-side, thus, making it easier to open and close.

Flexible wedge valves can withstand higher pressures than other valves which is why they are often applied for high-pressure applications.

A parallel slide gate valve has a disk that slides up and down in a track which makes it easy to open and close the valve. These types of valve gates are unable to withstand high pressures which is why they are used for low-pressure applications.

These types of valve gates are incorporated when the flow of fluids and particulates needs to be regulated. This is achieved through a wedge-shaped system that is guided by two bolts on each side of the valve’s body to move through the seat ring. This gate valve evenly splits tough materials such as oils, molten resin, and metals through consistent pressure.

Due to their mechanical design, split wedge gate valves offer a higher degree of safety towards sudden changes in flow rate. They are especially applied in petrochemical plants or construction sites.

Bellows seal gate valves respond quickly to low-pressure differences. In addition, their flexible construction allows higher temperature and pressure variations.

Bellow seal gate valves offer efficient solutions as they can also be implemented with advanced technologies to help users determine leakage rates.

Rising Stem Gate Valve with Outside Screw is also known as an OS & Y type (Outside steam and York).

The stem in this gate valve rises when the valve is opened and lowers when it is closed. This indicates the position of the gate valve. In this system, the stem threads are not in contact with the flow media.

This type of gate valve is also known as an insider screw valve and is threaded into the gate. In this system, the hand wheel and stem move together. The stem of this valve gate does not rise and fall and the flow medium is in line with the stem.

Valve gate systems cost more than other gate systems. It is thus better to use a valve gate for part geometry or applications that require it. You should note that valve gates give more control over quality and offer greater versatility.

To identify the most suitable valve gate for your machine, it is imperative to consider the following:

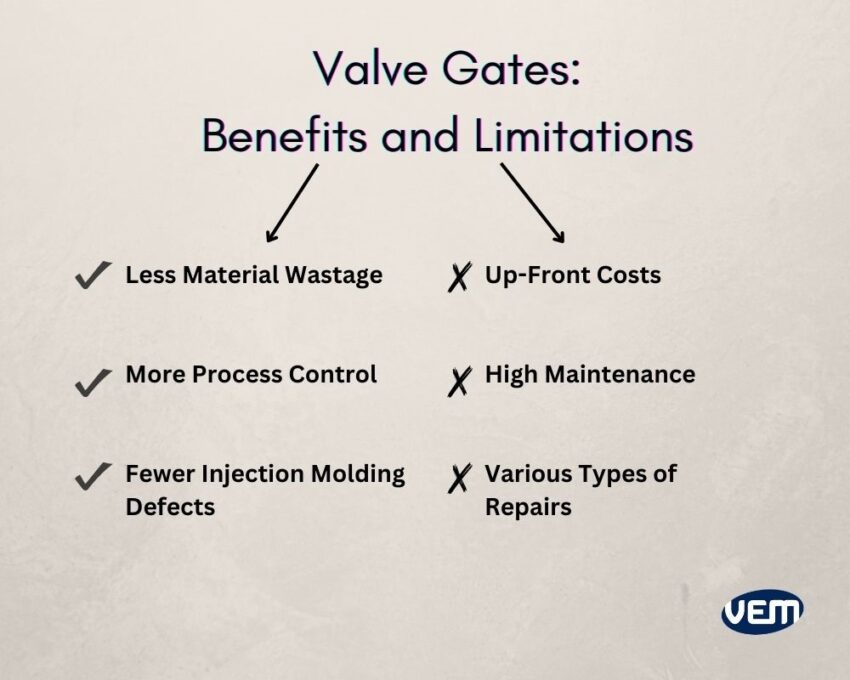

Reducing material waste is an excellent approach to reducing the parts per cost. This is especially the case in large production runs where the material usage is high.

Since the valve gate systems open and close during the injection cycle, there is very little material leakage thereby reducing the material waste. You should note that cold runners have a large sprue and runner system, whereas standard hot runners lack a valve gate shutoff system.

Valve gating systems enable control over the entire injection molding process. You can control the exact amount of material that enters the mold. You can also control when the material enters the mold. Thus, you have tighter control over the parameters that go into making a quality part.

Since valve gate systems enable tighter controls over the temperature and material flow, there is better control over the process which helps to avoid various types of injection molding defects.

When a valve gate is incorporated, it helps to hold the material in place which provides consistent control. This enables the creation of parts with fewer pressure-related issues like sinking.

If your project requirement is simpler and requires the production of smaller parts, then valve gates can incur a substantial cost. A single valve gate system can cost thousands of dollars, thereby increasing the mold cost significantly thus, it’s not the most cost-effective solution for most projects.

Valve gates also cost more in terms of repair and maintenance.

You should note that valve systems are more complex than other gate types. Valve gates have many moving parts and heating elements. These can break and, therefore, they need timely maintenance.

Valve gates cost more but they also offer tremendous value. They enhance component quality and increase production efficiency.

If you’re interested in utilizing valve gates for your mold, we can help you with the right solution for your project! At VEM-Tooling, we have an expert team of engineers who have experience in working with every type of valve gate.