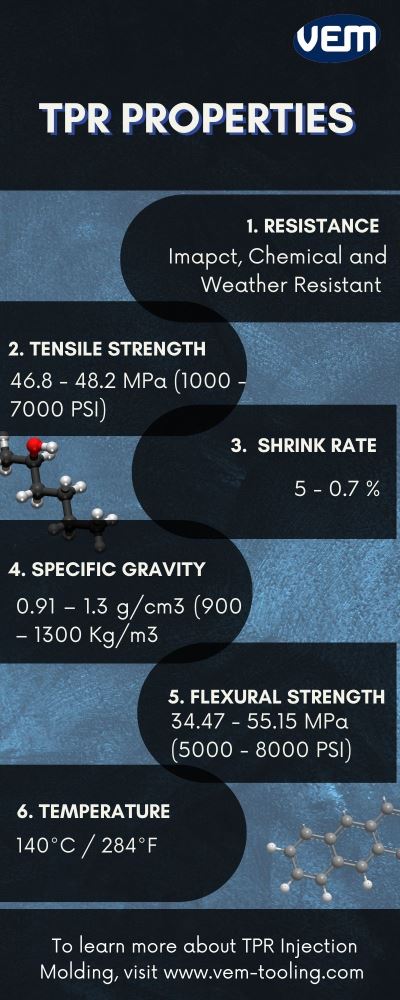

TPR, abbreviated for Thermoplastic Rubber, is a category of copolymer materials and has the characteristics of both rubber and plastic. Thermoplastic rubber has rubber-like properties and with its elasticity, it can effectively disperse impact energy, thus, reducing the impact force.

It is an excellent choice for injection molding due to its melt-processing properties. It is one of the best material choices if the project requires the plastic part to have rubber-like properties with good mechanical properties and chemical resistance.

Thermoplastic Rubber can be molded, shaped, and sized to fit the purpose and function of the product and it is suitable for processing via injection molding. TPRs are often compounded with plasticizers to decrease hardness and modulus, improve low-temperature flexibility, decrease cohesive strength or increase plasticity. In this article, we describe many of its details, properties, and its various types.

TPR combines the characteristics of rubber with the molding capabilities of thermoplastics. Thermoplastic rubber is a category of copolymer materials i.e. it includes a physical mix of both, plastic and rubber.

It is semi-crystalline and can be easily manufactured using melt processing techniques like injection molding. While TPR products not only display the physical features of rubber and plastics, they also exhibit thermoplastic and elastomeric qualities.

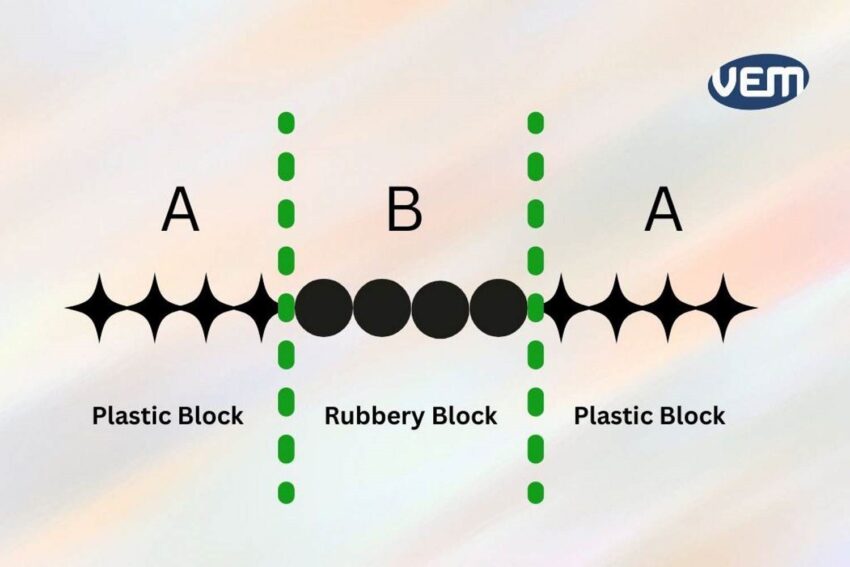

TPR exhibits polystyrene’s thermoplasticity and butadiene’s resilience. TPR has many variations and its simplest version consists of a rubber block in the middle with two plastic blocks in the end. It can be represented as A-B-A and is illustrated below:

Comparatively, TPR is a new polymer class. The origin of TPE can be traced back to the 1920s and to a scientist at B.F. Goodrich Company with the invention of plasticized PVC.

TPR was first commercialized in the 1950s, and since then, an array of variations have been developed. In the 1960s, TPR was applied to manufacture rubber shoe soles since it had rubber-like properties with the processing ease of thermoplastics.

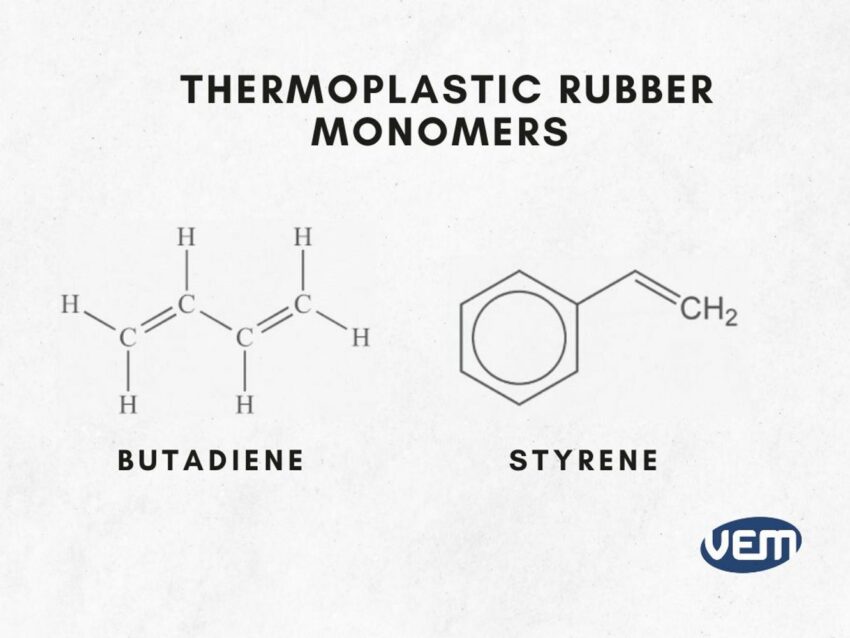

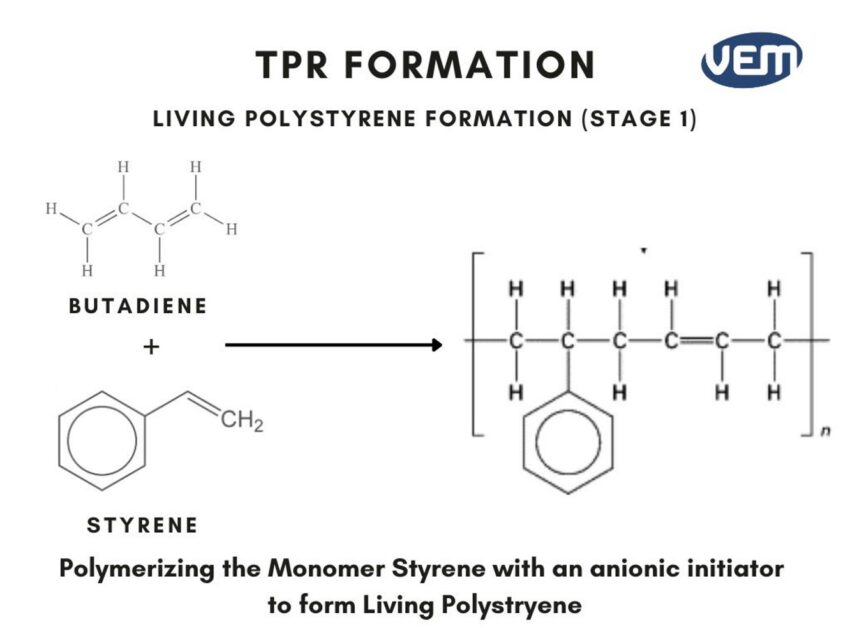

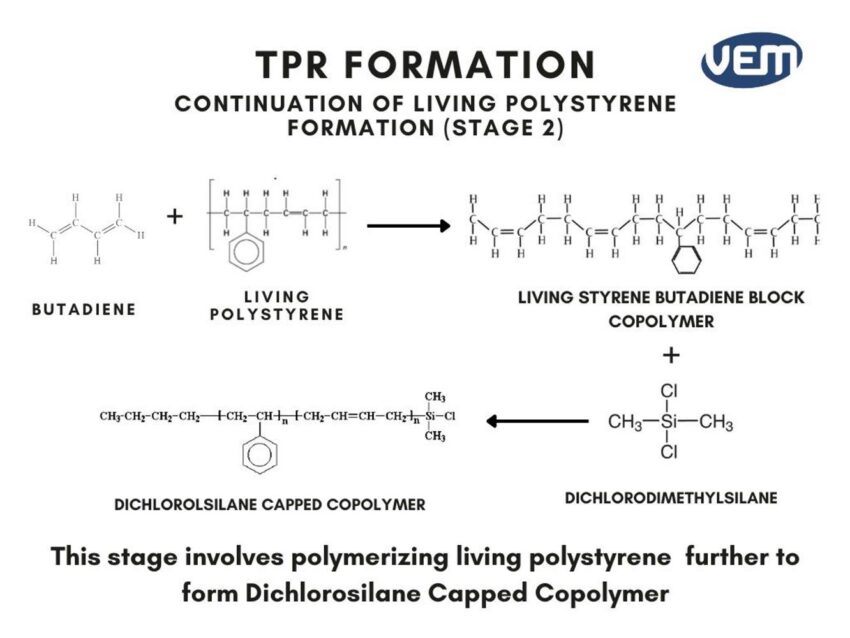

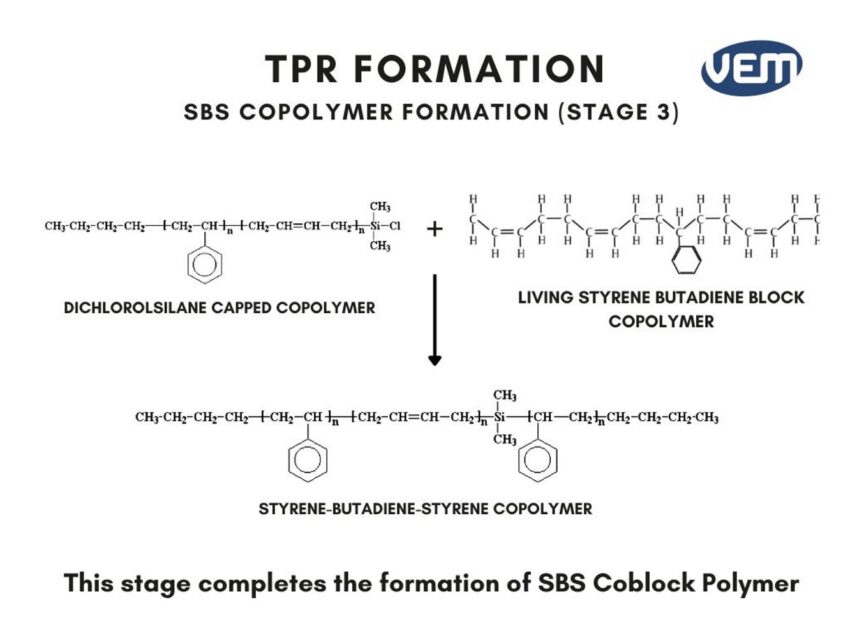

TPR is manufactured through a chain polymerization process of 2 monomers: Butadiene and Styrene.

These 2 monomers polymerize into Styrene-Butadiene-Styrene (SBS). TPR, a synthetic polymer, is manufactured through living anionic polymerization of SBS.

Styrene provides TPR with thermoplastic properties and butadiene is responsible for the elastomeric properties.

TPR is also referred to as TPE, abbreviated for the thermoplastic elastomer. They are often interchangeably used but they are primarily different from each other.

TPR is synthesized using block copolymers such as Styrene-Butadiene-Styrene (SBS) whereas TPEs are manufactured using quaternary block copolymers such as Styrene-Ethylene-Butadiene-Styrene (SEBS) based polymers thus, TPE and TPR are modified versions of different materials.

TPR and TPE, are both types of thermoplastics, and while, on the surface level, they appear similar, there are several differences between them thus, they are applied to different projects. Let’s understand some of the differences between TPE and TPR:

TPR is known for its hardness, while TPE is known for its softness.

TPR material provides increased flexibility as compared to TPE.

TPR emits thicker and darker smoke upon burning, as opposed to TPE, thus, it is possible to stretch TPE to moderate elongations.

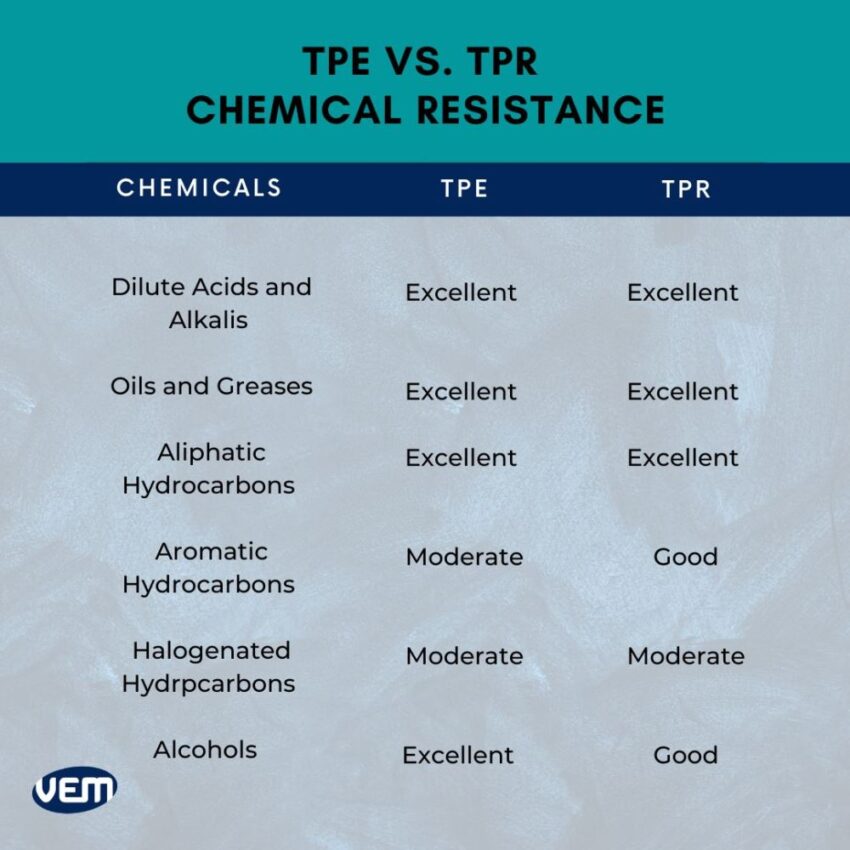

TPR and TPE both exhibit chemical resistance to dilute acids, alkalis, oils, and aliphatic hydrocarbons but they have varying chemical resistance towards alcohol, aromatic and halogenated hydrocarbons. The below diagram depicts the chemical differences between TPE and TPR:

Thermoplastic rubber has been a popular choice for the production of shoes and shoe soles since the 1960s. TPRs are easy to mold, lightweight, and have a great slip and flexing resistance. They are also inexpensive and they can be customized into an array of colors.

Due to rubber-like properties, it is popularly used to manufacture pumps, gaskets, hose connectors, and plugs in the appliances industry. The following picture indicates TPR in gaskets:

TPR is often used to manufacture various sporting goods such as grips and scuba equipment. The following picture indicates TPR in scuba wear:

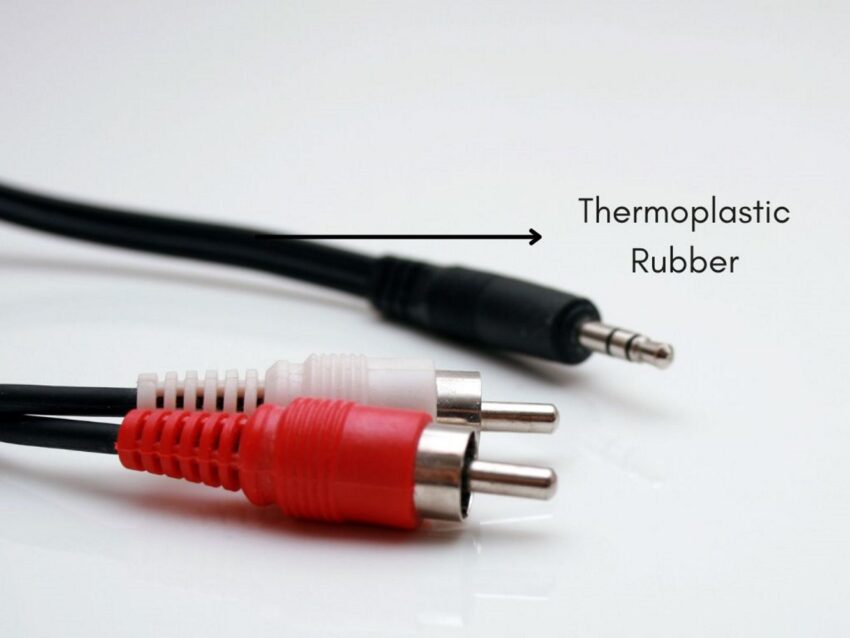

Another popular application of TPR is in the electrical industry for manufacturing molded connectors and cabling applications. The following picture indicates how TPR is applied to electrical industry products:

TPR has many unique properties that are desirable for some exclusive projects. It can be customized to enhance a particular specification which is why it can be applied to various applications.

VEM Tooling has the expertise for your TPR injection molding project. To better understand how VEM tooling can provide you with the expertise and serve you for your TPR injection molding project, contact us or request a quote today.

It is advised that TPR parts be cleaned with only mild soap and warm water. After cleansing with water, it should be wiped immediately with a clean and dry towel.

Yes, Thermoplastic rubber, like most thermoplastics, is waterproof. It is mainly used in products used for outdoor activity (mainly for waterproof soles in footwear). Soles made of thermoplastic rubber not only provide a good grip on slippery roads but are also lightweight with a rough texture.

TPR becomes heat resistant after cross-linking. However, excessive heat will vulcanize it and will yield water and silica after complete combustion.

No. TPR is synthetic and it does not contain any actual rubber-related compounds like latex. TPR is manufactured from styrene-butadiene-styrene polymer. Thermoplastic rubber is, therefore, ideal for applications that need the performance and properties of rubber but the material choice cannot be latex as latex is an allergen that may affect some people.