It’s a prerequisite of the manufacturing industry to create high-quality products which has led to the development of various casting techniques. These casting techniques have enabled manufacturers to create complex geometries with a high degree of precision and accuracy.

One such technique is the shell mold casting technique which is a type of metal casting process. In this article, we discuss shell mold casting, its process, and various benefits and challenges.

Shell mold casting, also referred to commonly as shell molding, is comparatively a new casting technique. It’s a type of metal casting process that involves pouring molten metal or alloy into sand and resin which is further heated and shaped to build a mold.

Shell molding was invented by Johannes Croning in 1944. Johannes Croning was a German engineer and businessman and he patented the shell molding process in 1943.

You should note that shell molding was originally referred to as the Croning process. It later came to be known as shell mold casting or shell molding.

Shell molding is known for its precision and its ability to manufacture complex shapes with intricate details. Compared to other metal casting techniques, shell mold casting offers an improved surface finish and can create more complex parts that have a higher degree of precision.

Shell mold casting is applied to various industries such as aerospace, medical, and automotive industries. It is especially popular in the automotive industry and is often employed to manufacture camshafts, gearboxes, crankshafts, cylinder heads, bearing housings, lever arms, and valve bodies.

The lifespan of shell mold casting products depends entirely upon the material and the application.

Shell mold casting products are durable as compared to other techniques. The primary reason for this is that, numerically, shell mold casting products have lower defects. Typically, cracking and corrosion commences or is accelerated due to a defect. Since, shell molding technique imparts a high-quality finish, it demonstrates good durability.

The performance characteristics largely depend upon the metals that are incorporated during the molding process but in comparison to other casting techniques, shell molding creates parts with high-quality finishes and excellent dimensional tolerances. In addition, shell molding products demonstrate excellent wear and heat resistance.

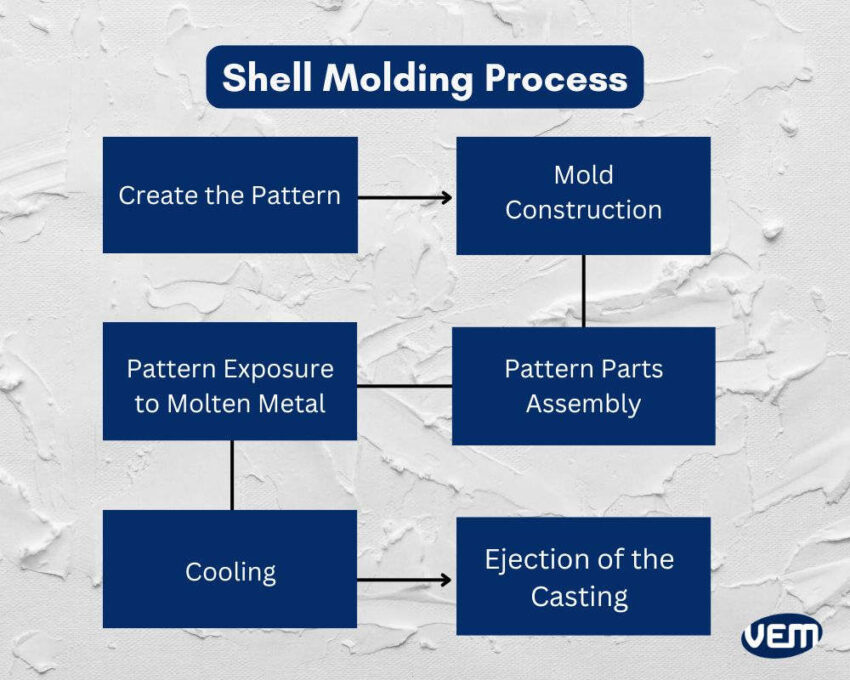

The shell molding process is a six-step process. Let’s understand these steps further:

The very first step in shell molding is to create a pattern part. Just like other casting processes, shell mold casting also requires a pattern for the part shape to be cast which is further employed to create the cavity into which the molten metal or alloy will be poured.

The patterns employed in the shell mold casting process consist of two metal pieces, such as iron or steel.

The patterns are typically created by machining a metal pattern tool into the required custom shape. You should note that each pattern in shell mold casting represents a part’s half while the second pattern represents the other half of the part.

Once the pattern creation is complete, the mold is created. In this shell molding process step, both pattern parts are heated and treated with a lubricant. The pattern parts are typically lubricated with calcium stearate and preheated between 175 to 370ºC / 347 to 698ºF.

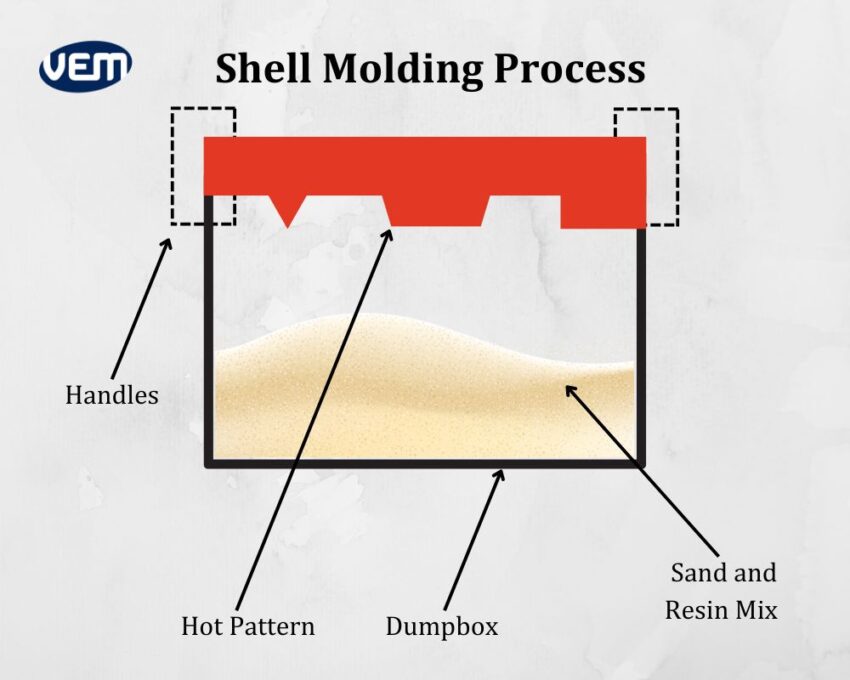

Now, the pattern parts are inserted into a dump box. A dump box is a large container that is filled with a mixture of sand and resin. Once the pattern parts are inserted into the dump box, the box is flipped so the pattern is in contact with the sand and resin mixture. The heat further causes the resin to cure. You should note that molds can be repeatedly created from a single pattern.

In this shell molding process step, the pattern parts are assembled. Once the shell is cooled, the process of pattern parts assembly begins.

Depending upon the pattern type, there may be a locking mechanism that clamps or holds the mold halves together. Once the pattern parts are secured, they are inserted into a flask where they are exposed to molten metal.

The molten metal can be poured into the flask either manually or via an automated machine.

Various types of metals and alloys can be employed for the shell mold casting process. Whether it’s a metal or alloy, the material will be heated into a liquid state after which it is poured into the mold’s cavity so that a hardened shell is formed.

Once the molten material is poured in, you must allow adequate time for the metal or alloy to cool at room temperature. When the pattern parts cool, molten material hardens to create a shell. If the cooling is rushed, then it can lead to changes in the structure and properties of the metal. The cooling time is dependent upon the volume and metal type involved.

The final step of the shell mold casting process is the ejection of the casting from the mold’s cavity.

Once the metal has cooled, the mold halves are separated. When the top and bottom pattern parts are separated from each other, the newly created casting can be safely ejected. This is done by separating them at their seam or simply breaking the mold. Since the shell mold casting process is a two-piece pattern, the castings are easily ejected by opening the pattern.

The completion time frame for shell mold casting depends entirely on the mold size and complexity. Certain pattern parts are more complex in geometry than others and thus, take longer to produce. Shell mold casting creates between 5 to 50 parts/hour. You should note that the completion time frame of shell mold casting is also largely dependent upon the automation process incorporated.

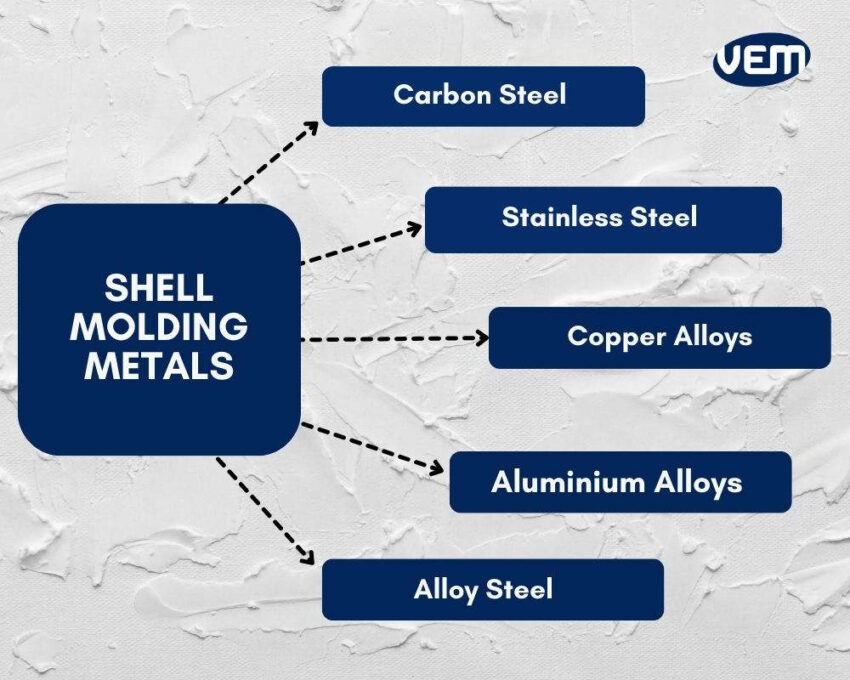

Various ferrous and non-ferrous metals are applied for shell mold casting. Let’s understand some of the most common metals further:

Carbon steel is an iron alloy and the grades that are typically employed for shell mold casting are C20, C25, C30, and C45. It is extremely machineable and wear-resistant but is more susceptible to corrosion than other steel types.

Stainless steel alloy is composed of at least 10.5% chromium. Stainless steel is corrosion-resistant and durable but demonstrates reduced tensile strength and is more brittle than carbon steel.

Copper alloys are generally suitable for shell mold casting. They are corrosion-resistant, lightweight, and ductile.

Aluminum alloys are not as strong as steel but they are lighter than steel. They also demonstrate good conductivity. The Aluminum alloys that are typically employed for shell mold casting are ASTM A356, A413, and 360.

Alloy steels vary in various characteristics such as density, strength, temperature, and corrosion resistance. The most common alloy steel grades employed for shell molding casting are 20Mn, 45Mn,40Cr, 20Mn5, 16CrMo4, 42CrMo, GCr15, and more.

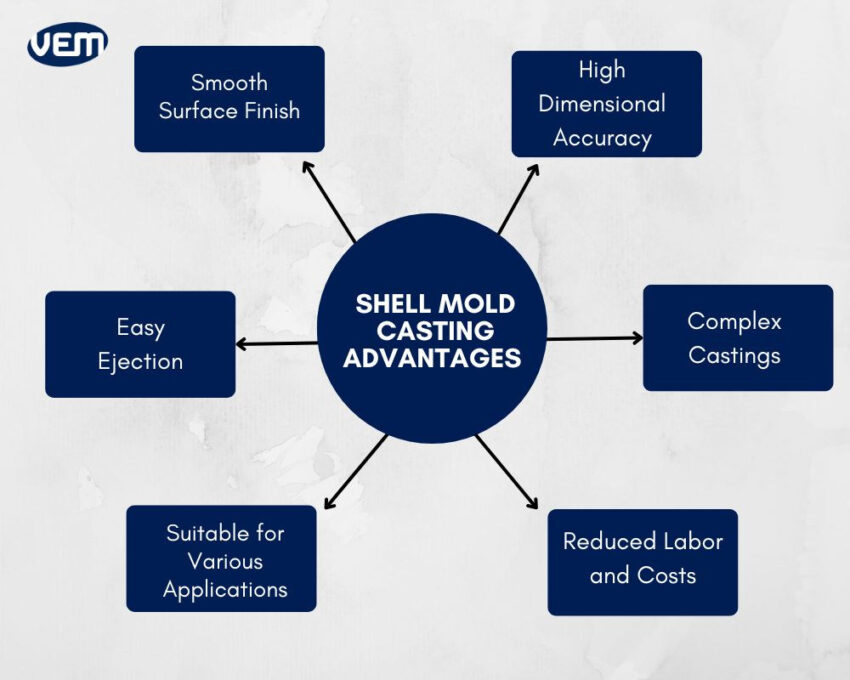

The smooth and hard surfaces of shell molds create castings that have excellent and high-quality surface finish.

The internal surface of the shell mold is very firm and extremely smooth which enables an easy flow of the liquid metal or alloy through the mold cavity while pouring of the casting. Thus, the shell mold casting imparts a smooth surface finish. In addition, there are fewer surface defects.

Shell molding is more accurate than most casting processes. The resin improves the surface finish of the sand pattern and this higher-quality surface finish is further, imparted onto the final part which creates a better-quality finish and tighter dimensional tolerances, leading to higher dimensional accuracy. It is possible to achieve a tight tolerance of 0.25mm / 0.010 inches with shell mold casting.

In addition, shell mold casting makes use of a hard mold which is why there is less expansion of the sand molds. This further helps to maintain tight tolerances.

Shell molding can create extremely complex structures. It is especially applied to create castings for thin-walled thickness structures and other complex geometries.

Shell mold casting enables easy ejection of the cast. Since the resin binder is burned in the shell mold casting process, it makes it easier to remove the final product.

Shell mold casting is a versatile technique. In this casting technique, both ferrous and non-ferrous metals can be employed to create a casting.

Shell mold casting reduces labor and costs as it can be performed with minimal to no machining. Comparatively, it has lower skill requirements for molding. In addition, the lead times are shorter and the tooling for shell mold casting is cost-effective.

You should note that the sand and resin mixture is reusable thus, reducing further costs.

Just like any other manufacturing technique, shell mold casting has an initial investment. These high initial investments are typically for the equipment that are required in shell molding. In addition, Shell molding needs to make use of metal patterns which adds to the expense.

Shell molding machines have a certain level of dimensional limitations. They are limited with respect to size and weight. Typically, the shell mold castings are limited to a weight of up to 30 kilos / 66 pounds and a size of up to 400 mm / 15 inches. If the weight or size is increased, then it cannot be manufactured via shell mold casting.

While shell mold casting is not part of VEM Tooling’s capabilities, we have 30 years of experience in producing plastic parts.

Building molds and running production, assembly and packaging projects is what we do best. If you have any project or questions, don’t hesitate to contact us.