Rapid prototyping, abbreviated as RP is a comparatively new technique in the manufacturing sector. As the name suggests, this technique is used to create prototypes quickly. This technique is usually applied in the manufacturing sector when a part or some of its features need to be evaluated either visually, functionally, or both.

Rapid prototyping is a technology that fabricates physical objects from plastic parts that are created in CAD. This technology can be applied at any stage of the product development cycle for any plastic parts and their components.

One of the biggest advantages of this technology is that it can be repeated various times to achieve the desired result. Manufacturers can also create individual parts separately and assemble them to test the design of the prototype. In this article, we explain the role of rapid prototyping in manufacturing and the various techniques that can be used to achieve this.

In order to understand rapid prototyping, let’s first understand what a prototype is and its role in manufacturing. A prototype can be described as a preliminary version of the end product. Prototypes are used to evaluate the design, test the technology, analyze the working principle, and provide final product specifications. Prototypes are integral to product design and extremely vital for new product development.

The prototype models that are produced through this method are often scalable, which means that the actual measurements that are used to make a prototype can be extrapolated on a large scale. Thus, prototypes help build a working prototype.

Rapid prototyping is an agile strategy that is adopted by manufacturers and is implemented throughout the product development process! This technology enables manufacturers to create 3-dimensional prototypes of a product or feature which can be then tested and optimized for various characteristics like shape, size, and usability.

Rapid prototyping helps product developers by creating product simulations for testing and validation. This technology helps to conduct various iterations in a short time frame in order to implement user feedback and analysis.

This technique is a fast-track process to validate any product hypothesis. Prototypes explain whether a product can solve the problem that it is intended to solve. It may not always be fully functional but it is supposed to be close enough to the designed product so that the potential users can interact with it and provide feedback.

If user feedback indicates that the prototype is not as per the idea, then the company can eliminate building something that may not be actually functional. Thus, it can save time, effort, and money. On the other hand, if the prototype is in sync with the product concepts, then the manufacturer can proceed with the development.

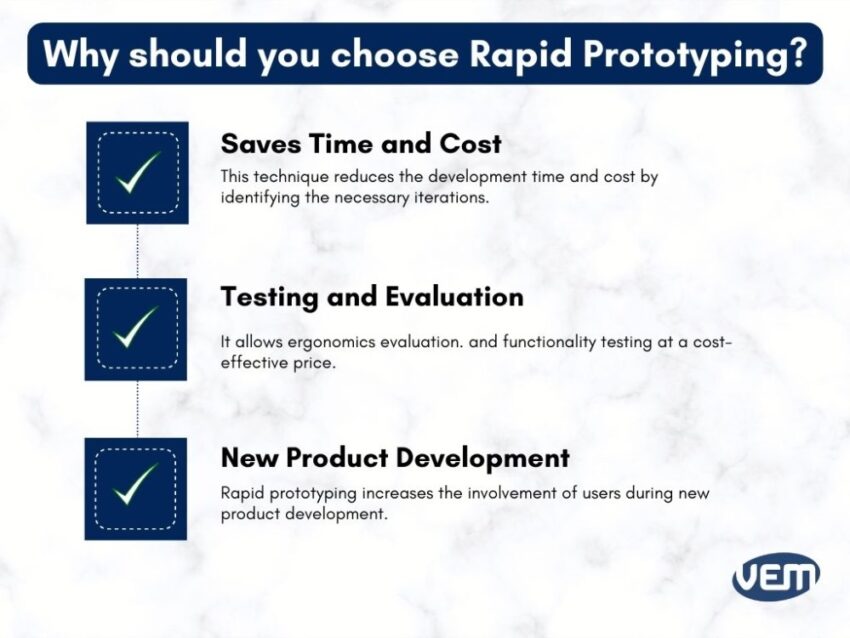

Today, the introduction and development of a new product design are more competitive than ever. Thus, it is essential for manufacturers to be competitive in this fast-moving modern-day consumer market. Innovation in technology and faster product development is vital which is why rapid prototyping is crucial to new product development.

Rapid prototyping helps manufacturers achieve the following objectives:

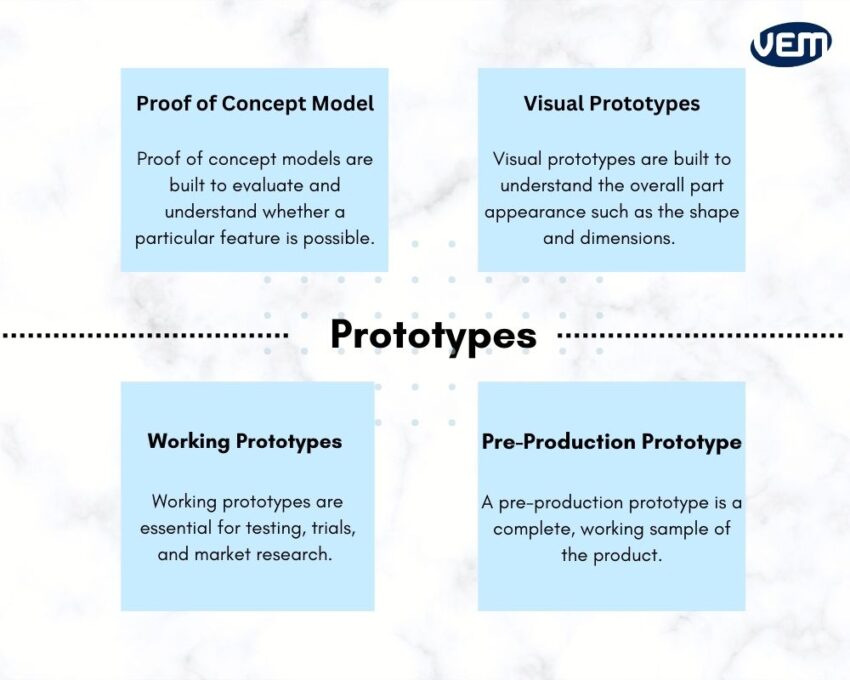

There are various types of rapid prototypes and it is crucial to understand these types before attempting the process of rapid prototyping your design.

In addition to various prototypes, there are also development stages during the product design and these various stages have different prototype requirements. For instance: In the early stage, an invention concept needs to be proved quickly and inexpensively. This instance may not require a full-scale functioning model but rather a proof of concept prototype that proves a particular functioning or a concept is possible. Let’s understand the various prototype types:

Proof of concept models are built to evaluate and understand whether a particular feature is possible. You should note that in proof of concept models, the data captured may not be accurate and the results may not be reproducible. Proof of concept models are not working prototypes but they are used to test a function or a feature.

Visual prototypes are generally, not working parts but they are used to understand the overall appearance of the part. They are used to showcase the shape and dimensions of the part. Visual prototypes are used for demonstrations to investors and early customer prospects.

Visual prototypes are usually simple 3D printed prototypes that can be roughly constructed using simple materials. Though visual prototypes are only used for visual representations, 3D printing techniques have enabled us to achieve extremely realistic-looking prototypes.

Working prototypes are essential for testing, trials, and market research. They are also used for demonstrations to investors and pitching. Thus, a fully working and functional prototype is essential for various product development stages.

A working prototype may not be the exact replica of the final part and is subject to change as the development of your product design progresses.

A pre-production prototype is a complete, working sample of the product. This is often a production sample rather than a prototype. It is built to ensure a 360-degree quality check is conducted before entering into full production. A factory sample is needed to ensure that there are no manufacturing errors.

It’s imperative to understand these differences as it helps to save time and money. We have listed some of the questions that you should ask as a manufacturer or a product development engineer:

Prototypes are also classified based on the accuracy required, and its purpose. They can be classified in terms of ‘Fidelity’ and this can vary from low to high fidelity and is based on functionality, appearance, user interface, and size. Let’s understand these two types further:

Low-fidelity Prototype: This type of prototype is simpler to produce and is used to quickly test broader concepts. They are simple prototypes that are low-tech concepts. The goal of low-fidelity prototypes is to convert ideas into testable objects. Thus, data can be collected for analysis and feedback in the early stages.

High-fidelity Prototype: These prototypes appear and function similarly to the expected product. They are highly functional and interactive with most of the design assets and functions integrated. High-fidelity prototypes are often used in the end stages to primarily test the usability of the part.

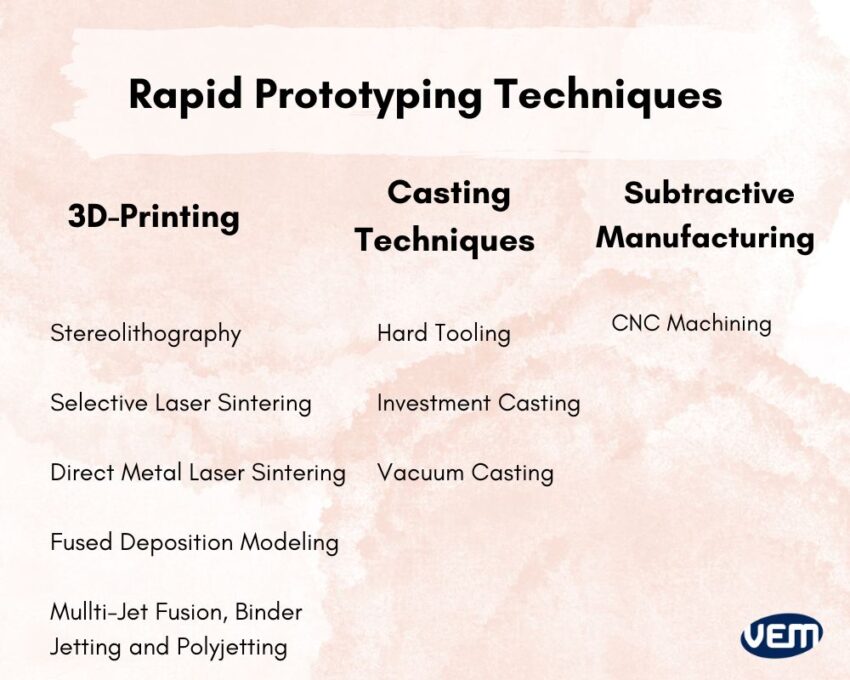

Rapid prototyping is a technique and there are various technologies to support this technique. It is vital to choose a suitable rapid prototyping technology as every technique has pros and cons with respect to material compatibility, fidelity, and development stage. Let’s take a look at various rapid prototyping techniques:

Stereolithography techniques build parts layer by layer through a UV laser or a light projector. The 3D printer uses a UV laser to track object layers. The resins are then solidified into a hard plastic. This continues until the final 3D part is complete.

SLA technique may require support structures but provides the ability to develop rapid prototype parts with excellent surface finish. It also demonstrates great dimensional accuracy.

Selective laser sintering is best used to generate prototypes that have a highly complex geometry. The SLS technique uses a laser to produce functional parts by sintering polymer powder, steel, Aluminium, Copper, and Titanium powder.

SLS parts have excellent tensile strength and there is no support structure required. On the disadvantaged end, SLS parts have a rough surface finish and they are also brittle. The Material options are limited. Some examples include PA11, PA12, PA12 Carbon filled and TPU.

SLS can be used for various applications that can range from quick prototyping to small-batch manufacturing.

This technique develops metal parts and prototypes. It fuses layers of metallic powder through a laser beam. A wide variety of metal alloys can be used in DMLS. The prototypes that are developed through DMLS have excellent material properties.

This technology prints parts by melting thermoplastic resins. The resins are extruded on a build platform layer by layer which is then later, solidified. It is possible to print complex plastic parts that are mechanically strong and sturdy through FDM. It is possible to print complex prototypes through FDM but one must realize that there is limited suitability for functional testing.

This technology is a 3D printing technology where a fusing agent bonds powdered material. Upon heating, they fuse to produce 3D-printed prototypes. This technology can print highly accurate prototypes that are durable and have excellent surface finish. It is one of the fastest 3D printing technologies but is also equally expensive.

This technology is comparatively cheaper than DMLS and is used to make cost-effective metal prototypes. In this technology, the binding agent is selectively deposited into a powder bed which then further solidifies. Binder jetting technology is not suitable for low-strength functional testing but can be used to prototype full-size assemblies to test user interaction.

Polyjet is a material jetting technology that uses photopolymers to create plastic parts. The resins are jetted on the build platform and they are then cured using a UV light. This technique is used to print smooth and accurate parts which is very crucial for concept models and full assembly prototypes. It can print thin walls and complex geometries but is not suitable for functional parts or testing.

Vacuum or urethane casting is used to rapidly prototype plastic parts and is ideally suited for small to medium pre-production stages. This technique is often used for functional testing.

Vacuum or urethrae casting uses silicone molds to make plastic and rubber parts under vacuum. There is a wide range of vacuum-casting resins available. On the disadvantage end, the thin and thick features may deviate from standard tolerance due to shrinkage.

Investment casting is often used to prototype die-casting parts. It is known for creating high-precision patterns that have a smooth surface finish. This technique creates plastic parts using wax patterns to make an expandable mold. The wax pattern is then melted before pouring molten metal. Once the metal solidifies within the mold, the mold is broken to remove the parts.

Through this technique, it is possible to cast parts that have highly complex shapes and intricate features.

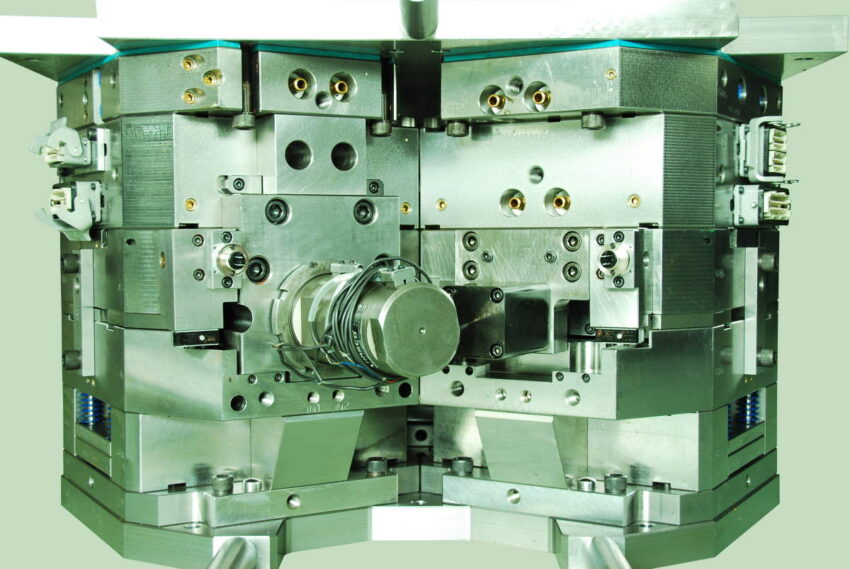

Hard tooling closely resembles the actual molding process of the injection molding technique. Hard tools can withstand multiple production cycles of up to 50K parts depending upon the material. They are often made of durable materials such as soft steel and Aluminum.

Hard tooling is suitable for producing durable high-precision parts and building accurate and complex prototypes. Though hard tooling has various advantages, it is considerably more expensive and time-consuming.

CNC machining is a subtractive manufacturing process. This technique is used if high accuracy and tolerance is required. CNC machining is one of the best methods for such prototypes. In this technique, metal and plastics are milled to create highly accurate complex parts.

Rapid prototyping and 3D Printing are often interchangeably used because 3D printing came into prominence as a way of making prototypes quickly but they are not the same.

3D printing techniques are rapidly evolving and have made giant strides toward manufacturing high-quality parts. In addition, additive manufacturing may not always be the optimal choice for developing some prototypes due to high costs. You should note that prototyping is an end-product result whereas 3D printing or additive manufacturing is a manufacturing process. In addition, other processes can also be used to develop prototypes via rapid prototyping.

Rapid prototyping can be extremely valuable in terms of saving time and costs for product teams. It aids product managers with dependable feedback from users and qualitative validation of their product ideas. This minimizes the risk of the final product failing to meet the product expectations.

Rapid prototyping techniques help product teams to experiment with various ideas. It also facilitates the development of a better design through visuals and minimizes the risk of missed requirements.

Rapid prototyping enables product managers to fast-track development by getting real customer feedback. This feedback is extremely valuable for developing products that are in sync with the requirements of the user. It helps to validate as well as eliminate assumptions! Rapid prototyping prioritizes the features and functionality of the product for the users.

Product managers must be quick in providing feedback to the developers as rapid prototyping has short turnaround times. They should be quick in analyzing and providing feedback in order to make the best use of this technique.

Prototypes can range from simple sketches to interactive simulations and look-alikes of the final product. The key to developing a successful product via prototyping is by implementing the feedback quickly.

There are various rapid prototyping processes that are available today that can be used to test your design. Our team has vast experience in rapid prototyping techniques. If you have any questions in determining which rapid prototyping is right for you, you can contact us and we will get back to you right away.