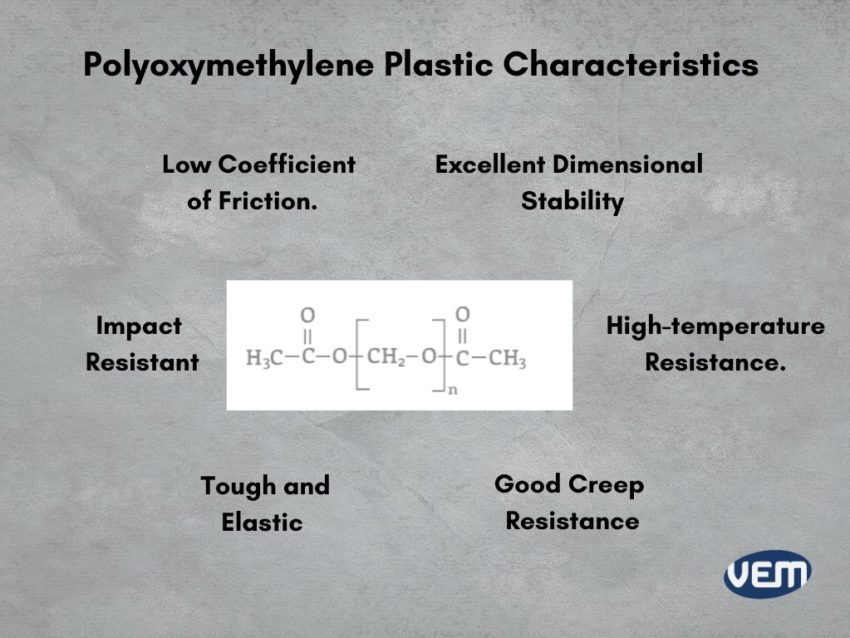

Polyoxymethylene, abbreviated for POM, is a semi-crystalline thermoplastic. It’s also referred to as acetal, polyacetal, and polyformaldehyde. POM demonstrates high tensile strength, an incredible creep resistance, a low coefficient of friction and excellent dimensional stability which makes it an ideal injection molding material for gears and bearings. It is also a popular choice for plumbing equipment such as valve and pump housings, and lawn equipment due to its high-temperature resistance.

In this article, we have conducted an in-depth analysis of POM injection molding material and its techniques to help you understand whether it’s best suited material for your project.

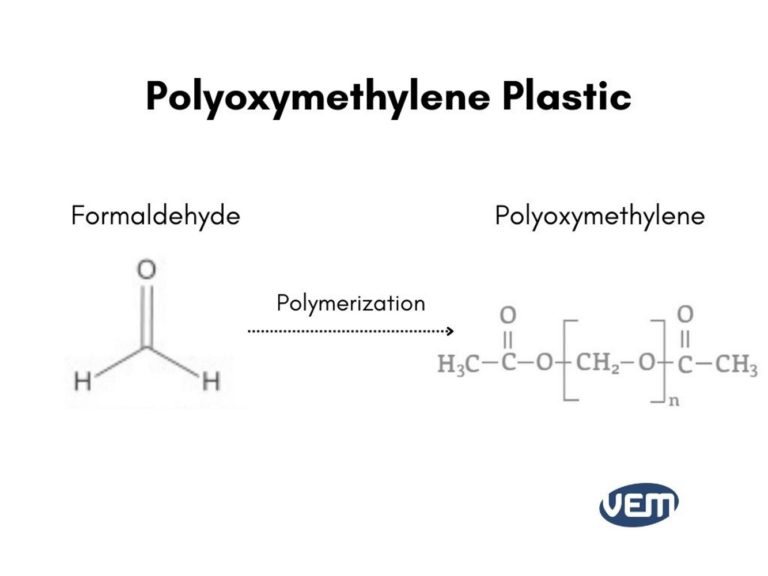

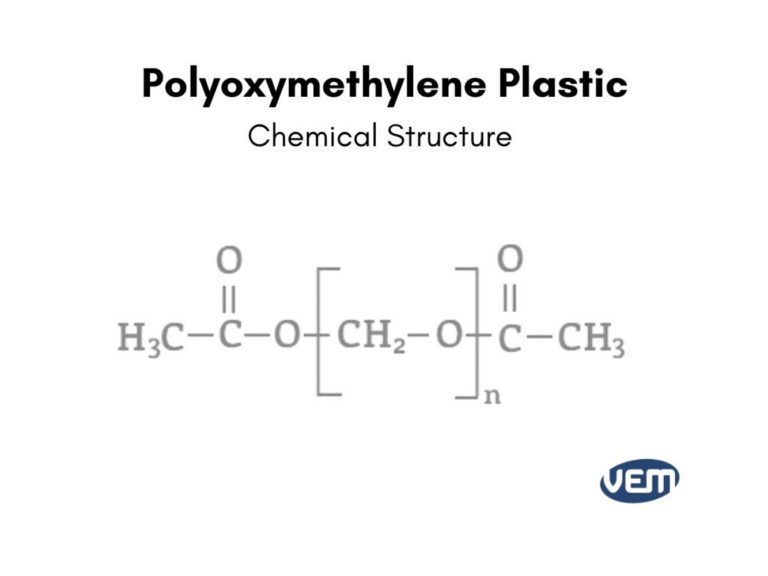

The following diagram illustrates the chemical structure of polyoxymethylene:

Homopolymer is produced from anhydrous, monomeric formaldehyde which is polymerized by anionic catalysis in an organic liquid reaction medium which is further stabilized by reacting to acetic anhydride.

Copolymer requires the conversion of formaldehyde into trioxane using acid catalysis and cationic polymerization. This reaction is then followed by purification of the trioxane through distillation or extraction. This removes water and other active impurities containing hydrogen.

Polyoxymethylene has several different names and they are often referred to by their technical or industrial names.

Polyoxymethylene or POM is also known by the following chemical names:

Brand names are basically trade names that refer to the product that has been developed by the company. The following enlist some of the famous POM brand names:

POM is not toxic in its solid form however, it can be harmful if it’s absorbed into the skin or eyes in its vapor or liquid form during the manufacturing process. That is why you will mostly find PP (Polypropylene) for consumer goods.

1. POM Plastic Processing:

Polyoxymethylene resins have a low water absorption rate which is generally between 0.2% to 0.5%. Usually, POM resins can be processed without drying.

In case the raw material is moist or wet, the drying temperature should be set above 80℃ for 2 to 4 hours.

2. Mold and Gate Design:

The mold and the gate should be optimally designed according to the plastic. In the case of POM plastic, the following parameters can should be paid attention to:

3. Melting Temperature:

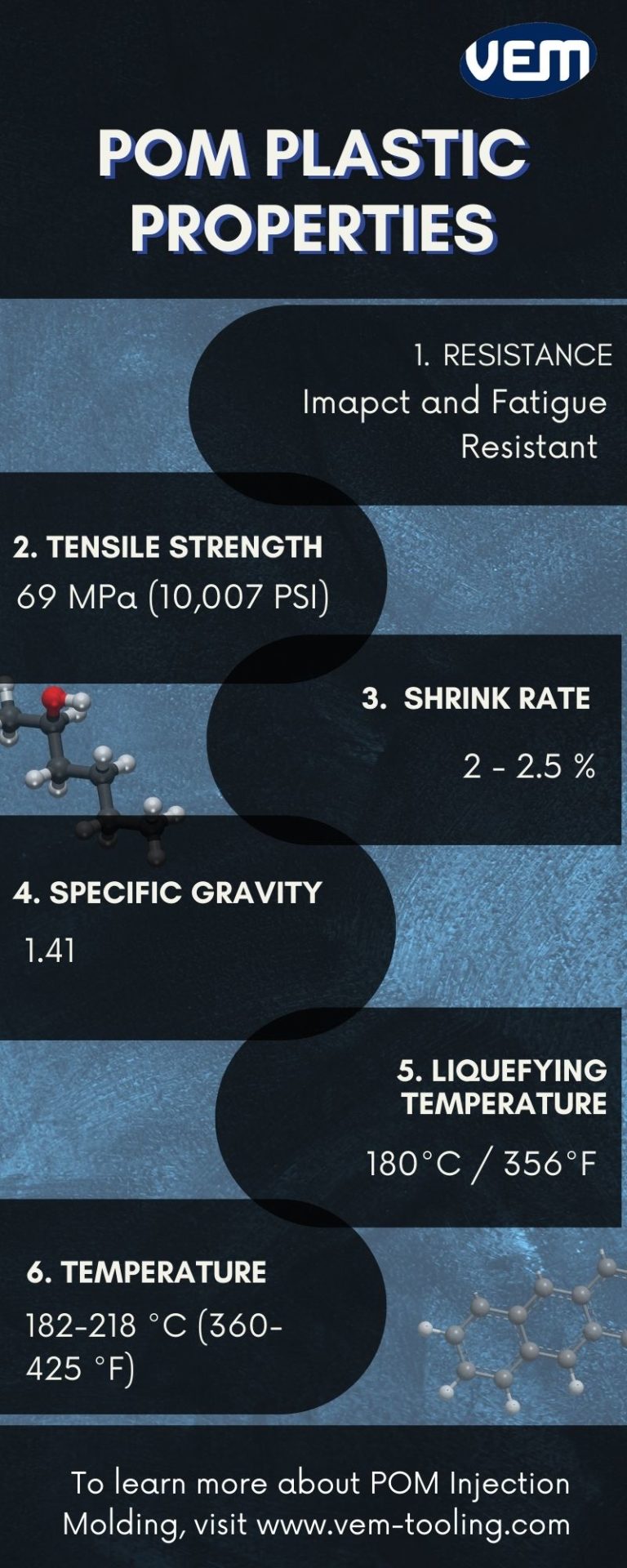

The melting temperature is as follows:

4. Injection Molding Speed

The Injection Molding Speed should be medium-fast. If it’s too slow, then ripples can occur. If it’s too fast, ripples and shear overheating can occur.

5. Back pressure

The backpressure should be as low as possible and it should not exceed more than 200bar.

3D Printing POM: Printing POM can be extremely difficult due to high temperature technicalities which is why it must be avoided.

CNC Machining POM: In the case of CNC machining, POM is widely used and there aren’t a lot of limitations.

Injection Molding POM: POM is available in the form of resins or pellets for injection molding. It’s easy to mold and it flows well within the mold if all the injection molding factors are adhered to.

It’s important to note that POM plastic shrinks at a rate of about 2%. This factor may be pronounced by a number of other factors such as holding pressure, melt temperature, mold wall thickness, mold temperature, and the type of additives.

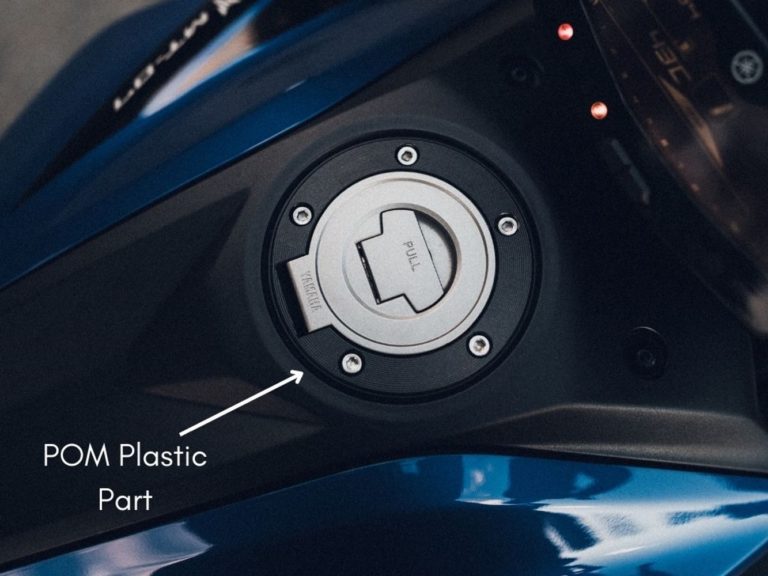

There are very few polymers that can withstand permanent contact with aggressive automotive fuels and the increasing temperatures encountered in engine compartments. Due to its high temperature resistant property, POM copolymer (POM) is the preferred injection molding material for modern fuel systems.

POM can be applied to various applications in the fuel systems such as fuel caps, fuel filler necks, lifetime filter, valves, fuel pumps, and fuel rails.

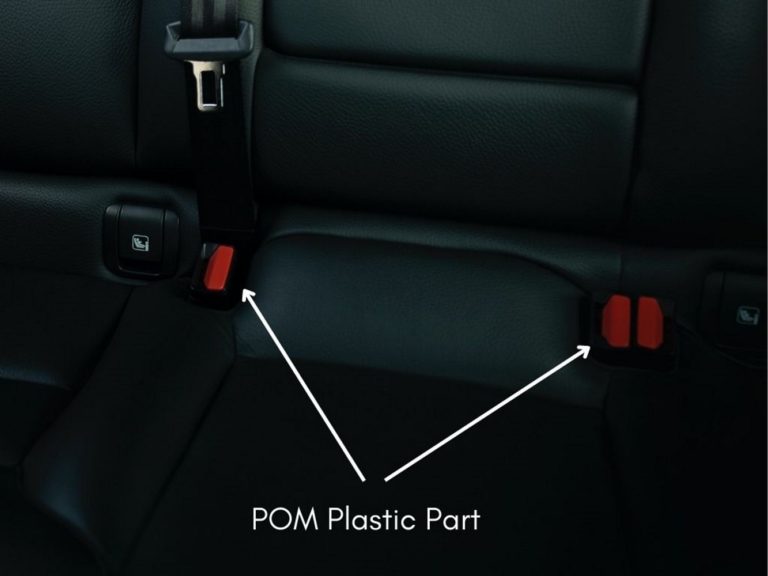

Polyoxymethylene plastic is often used in automotive interiors for soft, warm finishes as it can offer a molded-in low-gloss effect. In addition, it also provides design flexibility, excellent dimensional stability and is resistant to cleaning solutions. Take a look how molded parts for the automotive industry look in detail.

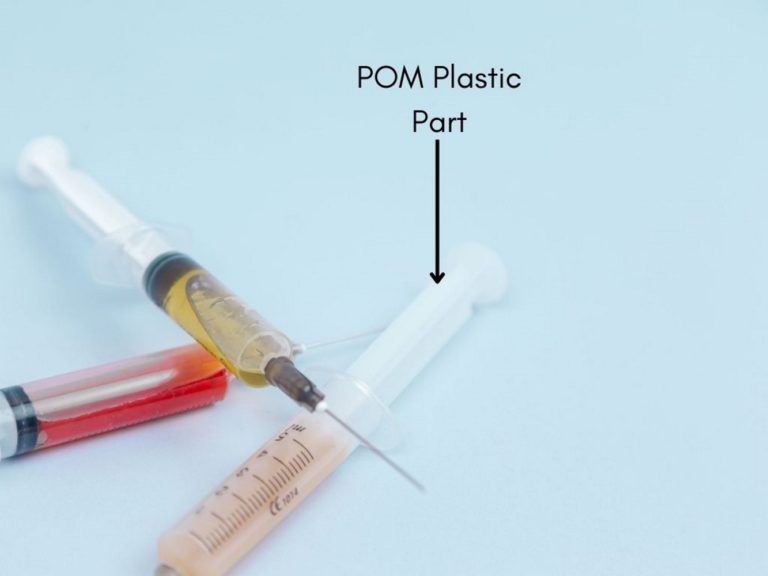

POM copolymers are highly-crystalline and easily processed. POM plastic is often a popular choice for medical and healthcare equipment as it delivers high strength, stiffness, toughness and lubricity over a broad range of temperatures and chemical environments. POM offers high purity and are FDA Compliant and pharma-friendly properties.

POM copolymer offers good flow and moldability. In addition, their very low moisture absorption permits dimensional stability when in contact with water thus, they are a popular choice for fluid handling applications such as plumbing, irrigation, water softeners, water filters, shower heads, and sprinklers.

POM Plastic is available in various forms that can range from resins, rods, films and sheets. We have listed some of the leading suppliers for POM Plastic:

VEM Tooling has the expertise for your POM injection molding project. At VEM Tooling, we offer a dependable service and ensure that you have a great experience with a seamless manufacturing process.

To better understand how VEM tooling can serve you for your POM injection molding project, contact us or request a quote today.