Injection mold tooling incorporates a wide array of materials. It is crucial to select the correct steel for your mold to achieve the expected requirements for your project.

Various types of metals are used to create and build molds. Some mold types experience extensive heat and pressure during the molding process and while some must be able to handle millions of cycles, other molds may be used only for prototyping. In this article, we discuss various mold steel types, their properties, and how to select one for your project.

Every component of an injection molding machine is crucial to the process and ‘the mold’ is one of the most important aspects for creating the final product in the manufacturing process. The mold is the main processing tool in manufacturing and its quality impacts the processing quality, precision, and output of parts.

The characteristics of the mold are largely influenced by the material that is used to make the mold and steel is considered to be one of the best materials for injection molds.

Steel is a versatile metal for molding and it can be implemented for both low-volume and high-volume production runs. However; not all steel types are the same. Typically, steel molds must be protected from erosion and this can be achieved through surface hardening or coatings.

If a mold isn’t hardened correctly, there can be an expedition in the wear and tear of the mold. You should note that molds with sharp edges are more susceptible to these types of defects.

Mold steels are used to manufacture molds such as die-casting mold, cold-punching mold, hot forging die, and more. There are various types of mold steel grades and their specifications significantly impact the processing, service life, and precision of the mold. You should also note that the properties and the heat treatment of the steel have a huge impact on the mold quality.

Mold steels are made up of various metals and they are categorized in groups based on their composition. Tool steels are chemically composed of the following:

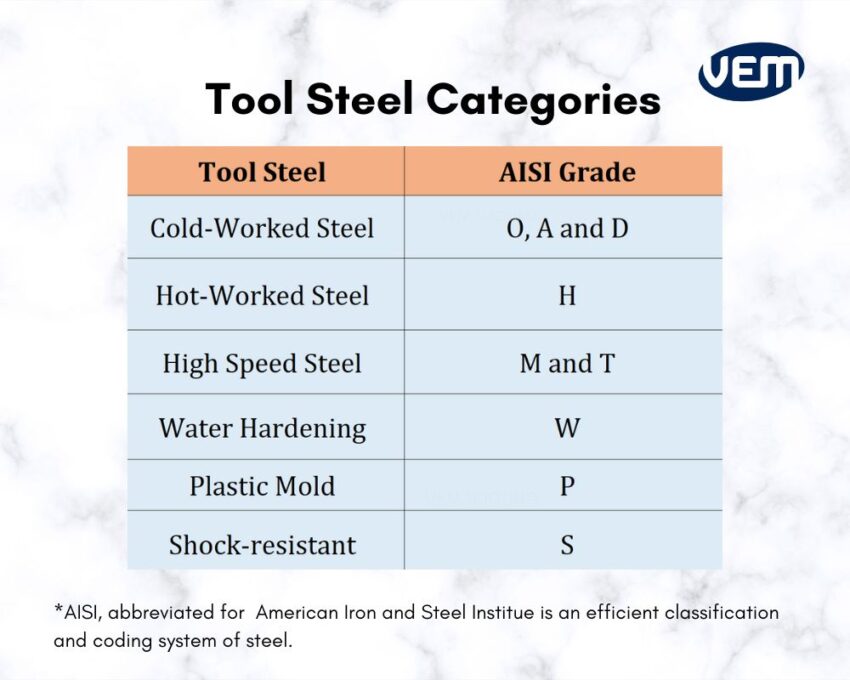

They are typically categorized as water-hardening, hot-work, cold-work, shock-resisting, plastic mold, and high-speed tool steel. The following infographic illustrates the categories of tool steel:

When a mold is created, it is subjected to various types of processes, treatments, and testing and it is important that the material demonstrates properties that support machinability, malleability, and more. Let’s understand the various properties further:

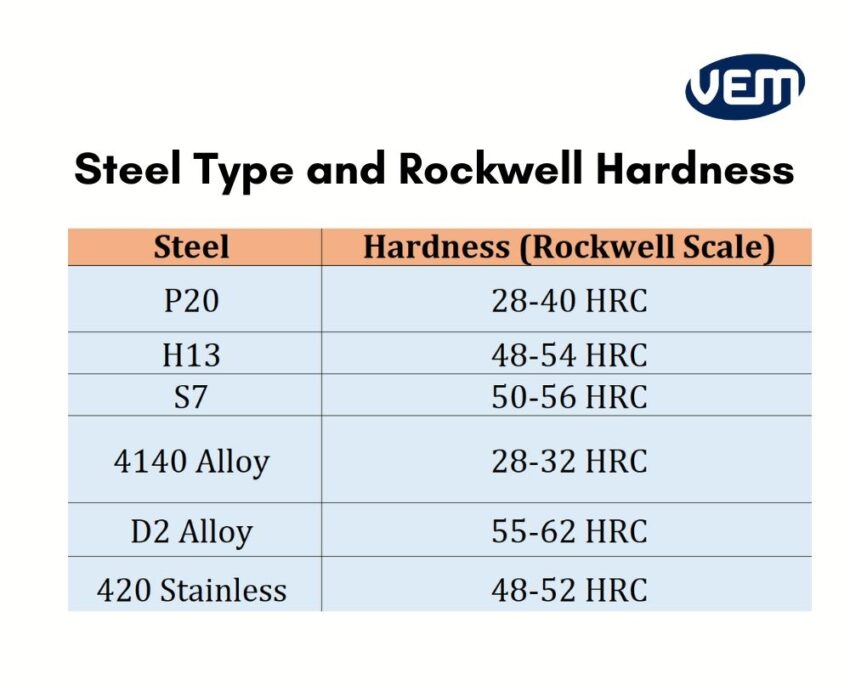

Hardness is defined as the material’s ability to resist indentation and deformation. The hardness of the material can be measured either through the Rockwell or Brinell test. It is typically expressed by Rockwell hardness HRC and for most mold steel the hardness is up to 62 HRC.

Steels incorporated for manufacturing molds are typically subjected to hardening to improve the mold’s capacity to handle abrasive resins and prevent plastic deformations. Mold steels that are hardened demonstrate an enhanced wear resistance and thus, are cost-effective in terms of maintenance and exhibit longevity.

In terms of hardness, there are two types of steel: pre-hardened and hardened.

Wear resistance is one of the most important properties of mold steel as it impacts various factors such as mold’s post-processing, part accuracy, overflow removal, etc.

Wear resistance is the ability of a material to resist mechanical wear and is determined by the hardness of the steel and its chemical composition. Mold tool increases its wear resistance either by hardening the metal or through the addition of alloys that tune the properties of the metal. If the hardness is high and the loss is low, then the wear resistance of the mold will be better. You should note that both the properties i.e. the hardness and wear resistance are inversely correlated to each other. Thus, if you require a mold with an increased wear resistance, then you must use hardened mold steel.

The mold usually undertakes high pressure and huge impact loads thus, the mold steel must demonstrate excellent strength and toughness. You should note that the durability of the mold steel largely depends upon the carbon content and the material’s texture.

When the temperature is high, the hardness and strength of the material reduces. Tool steel must be resistant enough to withstand high-temperature environments.

Plastic has various types of chemicals such as chlorine, fluorine, HCI, HF, etc. which upon heating and decomposition may be released and attack the mold surface thus, the mold steel that you choose must be corrosion resistant.

Toughness is the tool steel’s ability to withstand sudden shock and resist fracture due to impact or other stresses. It is measured either through an IZOD or Charpy impact test. Tougher steels work best for high-production runs with abrasive materials.

Toughness failure could be due to insufficient toughness of the material, heat treatment, lubrication process, or any other operating condition. You should note that the steel’s toughness can characterize its resistance to fracture but not its service life.

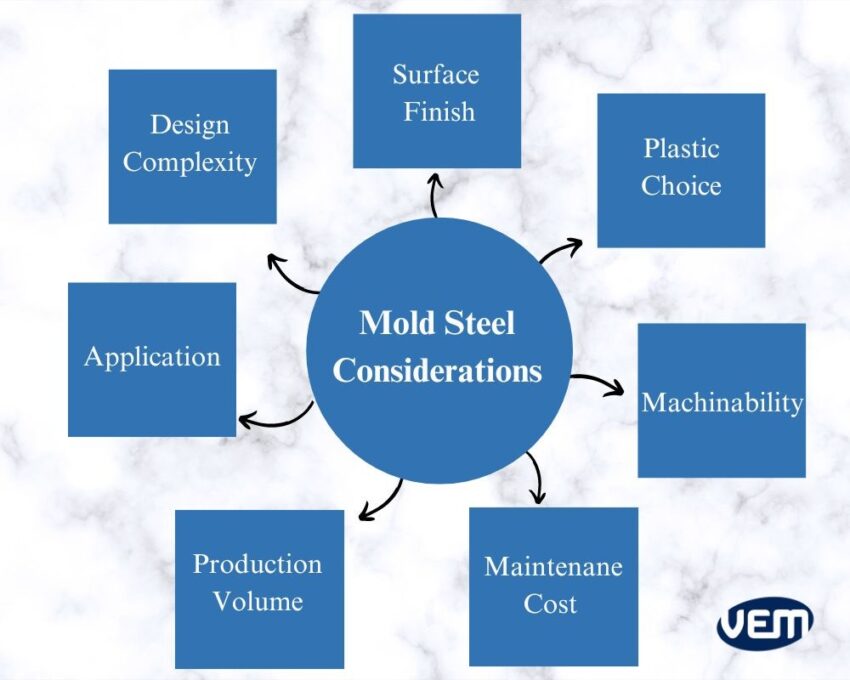

Many factors must be considered when selecting steel for your mold such as the type of molding material, its application, production volume, maintenance, etc. Let’s understand these aspects further in detail:

The first consideration factor for choosing the correct mold steel for your project is the application of your project. There are various types of mold steels and they are selected for the particular application depending upon their composition, temperature range, and the type of hardening they undergo.

The design complexity of the part is a major consideration factor for the mold steel. Complex geometries require precise machining, which can be handled only through certain grades of mold steel.

The next factor that must be considered is the surface finish of the part. Tool steels that can be hardened to higher levels impart an increased polishability. If the part requires a smoother surface finish, then the mold steel needs to be harder, in order to allow high polishing.

The resin directly affects the selection of the tool steel. Certain plastics need to be processed at higher temperatures and thus require hardened mold steels with high melting points.

Each type of resin has specific tolerances that need to correspond accordingly with the mold steel. If the resin is abrasive, then the tool steel must be tougher. For instance: Glass-filled resins require hardened steel to prevent mold wearing thus, hardened mold steels such as 420 stainless steel, H-13, and S-7 work well with glass-filled resins due to their excellent wear resistance.

The material’s machinability is the next factor that must be considered when choosing a mold steel.

You must consider the chemical composition of the mold steel. When the carbon content increases, the machinability decreases. In addition, the higher the alloy composition, the more difficult it is to machine.

Hardness is yet another crucial factor that affects the machinability of the metal. The general rule is that the harder the mold steel, the harder it is to machine it. A mold steel with a low hardness level is easily machinable but will not ensure the mold’s precision or longevity.

The cost of the tool is an important aspect that is to be considered. It is, however; a one-time upfront cost. The maintenance, on the other hand, can be a recurring cost and directly affects the tool’s productivity. It is thus a crucial aspect to be considered when choosing tool steel.

If the requirement of your part is a hardened tool steel, then though the tool cost might be more, it will require less maintenance.

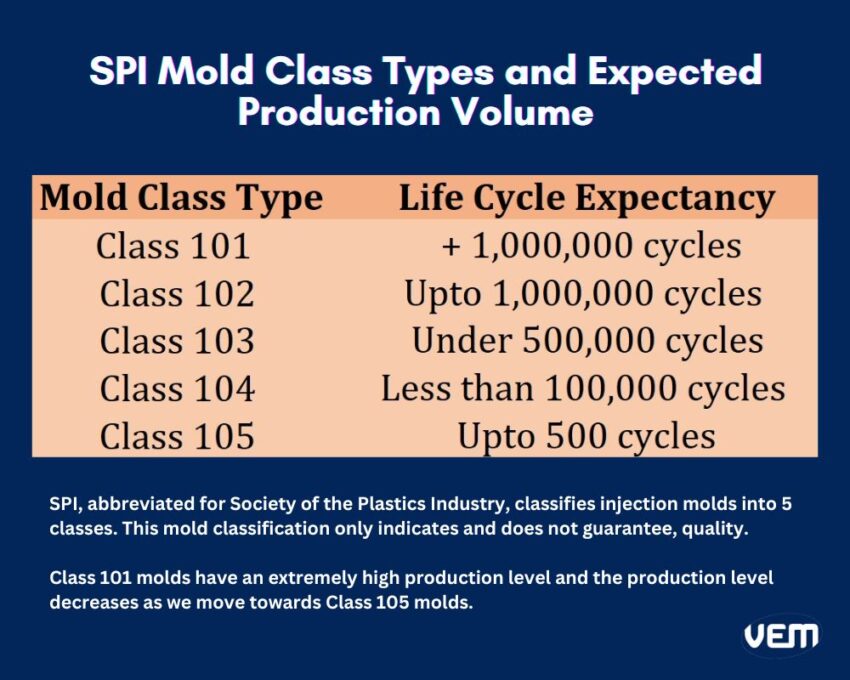

Mold standards are categorized into five classes by the plastics industry association and they are designated as Class 101 to 105. This particular classification is referred to as the SPI Classification.

Class 101 molds have an extremely high production level and this production level decreases as we move towards Class 105 molds. Thus, the SPI Class of the mold indicates the production volume which in turn influences the selection of your mold steel.

You can read more about mold classes in our Mold Life Expectancy article.

There are various types of mold steels and each type has its advantages and challenges. You should note that the selection of injection mold steel is largely dependent upon the product design and the plastic material of the part. For instance: If the plastic material is abrasive, a tougher steel will be required to avoid damage. Let’s understand the most popular types of tool steels further in injection molding:

P-20 is a pre-hardened steel that is one of the most popular mold steel for manufacturing via injection molding. It can be used as a base or for applications that require shallow cavity molds, sprues, and sliding inserts. The most common plastic materials that can be molded in P20 tool steel are polypropylene and polyethylene along with other similar resins.

P20 is best applied for low to medium-volume production runs. It’s a versatile mold steel that can be cast directly and machined fairly easily. It also does not require further heat treatments thus, giving faster lead times on tooling. It can also be repaired by welding and nitrided to achieve additional durability. P-20 Mold steel demonstrates the following features:

H-13 mold steel is a chromium-molybdenum-vanadium steel known for its excellent tensile properties, wear resistance, and thermal fatigue resistance. H13 is typically applied for high-volume production runs and molding of abrasive plastics as it can be hardened to Rockwell 52 (HRC). It also has good heat conduction and can be hardened to higher Rockwell levels. It can withstand thermal fatigue which is why it is perfect for high-heat applications.

H13 is the steel of choice for high-volume production runs as it can handle millions of cycles. You should also note that when the production volume is high, H13 steel is a preferred choice over P20 or Aluminum mold steel. It is costlier than P-20 steel but cost-effective for high-volume production runs.

H-13 Tool Steel demonstrates the following features:

S-7 tool steel is a part of the S, abbreviated for shock-resisting mold steels. It is a versatile tool steel that can work in both, hot and cold applications. It is ideal for manufacturing parts requiring tight tolerances.

S7 Steel is designed to endure high stresses, significant impacts, and vibrations. Since it demonstrates excellent impact resistance, it can be applied for moving components such as ejector plates and sprue bushings without nitration.

S 7 Tool Steel can be hardened to 56 HRC. You should note that S7 steel is typically not entirely applied as a mold base but as a component. It complements P-20 and H-13 and works well in conjunction with complex geometries since the steel can be machined easily.

S-7 Tool Steel demonstrates the following features:

4140 alloy steel is a chromium-molybdenum medium-carbon steel that demonstrates excellent strength, toughness, and wear resistance. Its well-balanced properties make it a suitable mold steel for an array of applications. You should however; note that this particular tool steel is heat treatment sensitive i.e. it needs to be heat treated to achieve the desired properties.

4140 Alloy Tool Steel demonstrates the following features:

D2 alloy steel is a high-carbon, high-chromium mold steel and is a cold-work steel.

It is an excellent choice for various applications such as dies and cutting tools. It’s also suitable for high-wear applications such as metal injection molding or highly filled polymers for injection molding.

D2 alloy steel demonstrates high abrasion resistance and resistance to deformation at high temperatures.

D2 Alloy Tool Steel demonstrates the following features:

420 stainless steel is a high-quality mold steel containing 13% chromium and is generally preferred for custom injection molding. 420 Stainless steel tool molds can handle high production volume runs and are the preferred choice for processing corrosive materials such as Polyvinyl Chloride (PVC). It’s an excellent choice for applications in the medical, electronics, food, and automotive industries due to its increased resistance to highly corrosive materials. 420 stainless steel tool mold can be hardened to Rockwell 52 HRC.

420 Stainless Tool Steel demonstrates the following features:

Copper alloys such as beryllium copper exhibit superior thermal conductivity and due to their ease of machining, it’s possible to achieve complex core designs. Copper alloy cores are applied to reduce cycle times on high-volume tools.

Copper alloy steels are perfect for molds that require fast heat transfer and high-quality surface finishes however; it does have a low strength. It is often a choice when cooling channels are not feasible to cool down the plastic part enough.

Choosing a mold steel for your project can be extremely daunting so we have enlisted some key pointers for selecting a mold steel.

The selection of mold steel depends upon an array of factors and it is crucial to ensure that your mold tool not only matches the part design but also manages operating issues and tool damage.

VEM-Tooling has over 20 years of experience in creating molds, analyzing mold designs, and manufacturing high-quality plastic parts. We not only help you to select the most suitable and economic steel for your project, but also create state-of-the-art molds out of it.