Today, injection molding is one of the most popular and effective manufacturing processes for producing plastic parts in large volumes. You should, however; note that the tooling costs that are associated with injection molding can be expensive and thus, they should be considered as an investment. Mold development is an expensive segment in injection molding that is responsible for giving shape and form to molten plastic and requires the utmost precision and accuracy.

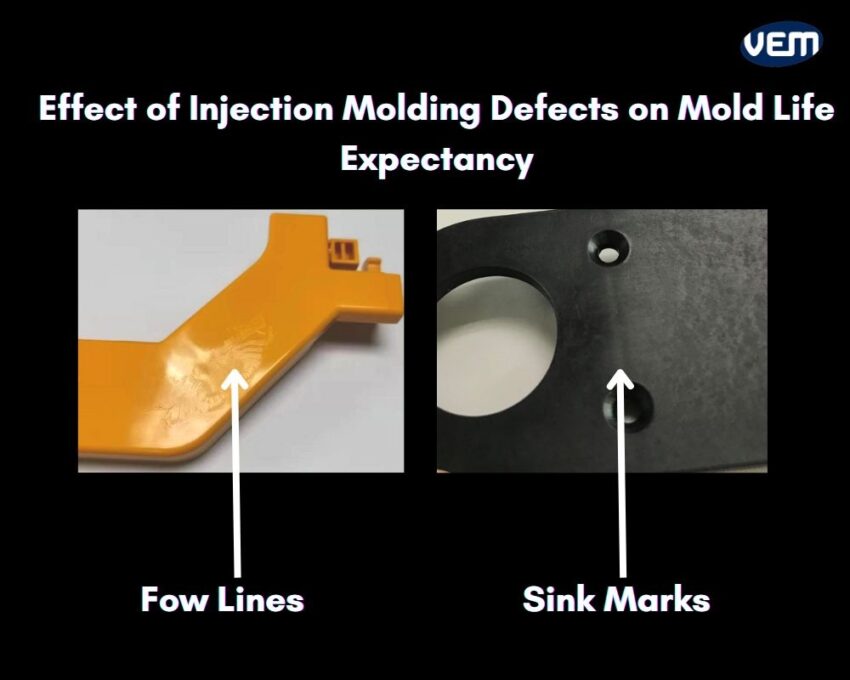

The life expectancy of plastic injection molds can range between hundreds to over a million cycles and the durability depends on its environment, maintenance, materials, structure, molding conditions, structure design, and other factors. It’s also imperative to optimize injection molding processes to avoid defects such as sink and burn marks, flow lines, and surface delamination since these defects impart damage to the mold.

Injection molds can be maintained to extend their lifespan by inspecting, maintaining, and coating the mold, as well as ensuring that the mold operates under appropriate conditions. In this article, we explain in detail the basics of injection mold lifespan, the factors that affect injection mold life expectancy, and what should be done to increase the longevity of the mold to achieve the best results.

Injection mold life refers to the molding cycle that a particular mold can perform. The life expectancy of an injection mold is measured in its expected number of production cycles where each cycle corresponds to the opening and closing of the mold.

There are various factors that can affect the injection mold life expectancy, however, the most prominent ones are the mold class, operating conditions, environment, maintenance, and type of materials.

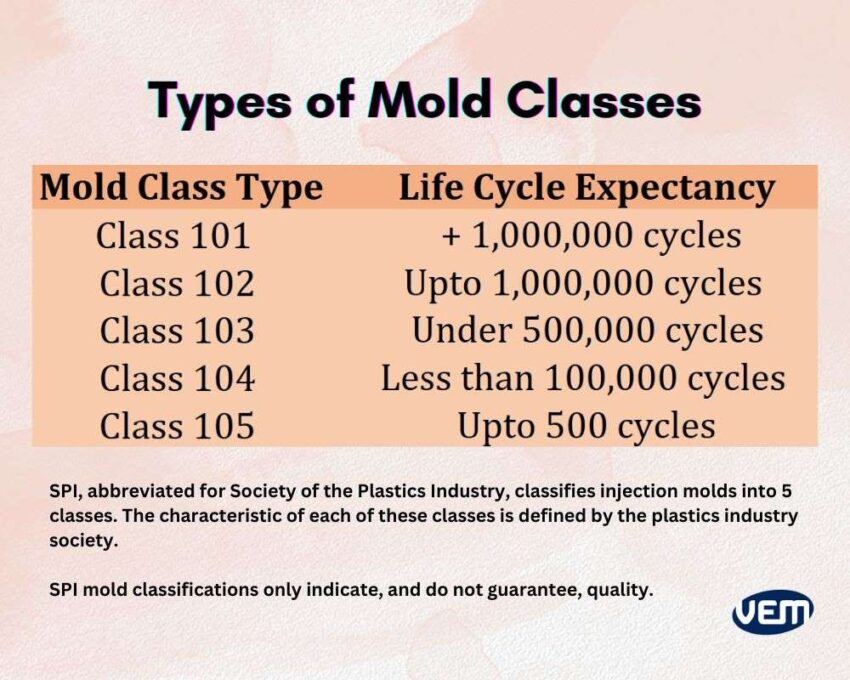

One of the most significant factors that affect injection mold longevity is its mold class. The SPI, abbreviated for Society of the Plastics Industry, classifies injection molds into 5 classes. The characteristic of each of these classes is defined by the plastics industry society.

You should note that SPI mold classifications only indicate, and do not guarantee, quality. For instance: An aluminum mold can last for a very long time whereas Class 101 mold can fail faster if maintenance is inappropriate. Let’s understand the 5 different types of mold classes further:

Class 101 Mold is the most expensive injection mold because they are made from the highest quality steel. They are usually more expensive because better steel materials are used, which are more durable. Generally, every mass-production application will apply a Class 101 mold as it is suited for 1,000,000 or more shots.

Class 101 molds are suited for harsh and corrosive base materials that can damage other mold classes. Class 101 molds generally have the following properties:

*HRC, abbreviated for Rockwell Scale / Rockwell Hardness is a unit of measure for hardness.

Class 102 mold is not as expensive as class 101 but it is still an expensive mold class. Class 102 molds have a lower life expectancy of up to 1,000,000 cycles. Class 102 molds work perfectly well till one million cycles and are generally an excellent choice for medium to high-volume production. They also can sustain harsh environments but not as well as Class 101 Molds.

Class 102 properties have similar properties to class 101 with some differences. These differences include plated cavities and corrosive-resistant temperature control channels not being mandatory.

Class 102 mold specifications include the following properties:

Class 103 molds are a great choice for medium-level production cycles. They have a maximum lifespan of 500,000 cycles. It is the average mold according to industry standards. The Class 103 mold requirements are not very stringent. Class 103 molds generally have the following properties:

Class 104 mold is a lower-quality mold class as compared to the above three. It has a lower life expectancy of 100,000 cycles and has many mold maintenance requirements. They also damage easily and are thus unable to handle abrasive resins.

The mold bases can be made of aluminum and mild steel and the same can be applied to the cavities and cores.

Class 105 molds are the least expensive mold class and they have the lowest life expectancy. Class 105 is usually reserved for less than 500 cycles and is generally a choice for prototyping projects and other low-volume applications.

Class 105 Molds can be manufactured out of cast metal or epoxy. The idea is here, to manufacture the mold in the least expensive way possible.

When we discuss injection mold life expectancy, we must take the mold material into consideration. The longevity of injection molds is highly determined by the material i.e. if it’s manufactured with aluminum or steel.

Aluminum is generally not preferred for injection molds even though it’s easier to machine because it’s softer. Aluminum is not a viable choice for high-volume productions but it is an excellent choice for class 105 molds that are for prototyping. Aluminum molds have a lifespan of anywhere from 2,000 – 10,000 parts depending on the Aluminum type, part material, and geometry. Steel tools can exhibit an excellent lifespan of 100,000 + parts depending on the steel material and part geometry.

Steel is known for its durability and is often used for high-volume production. Steel injection molds deliver longer life runs which is why they are more cost-effective than aluminum molds. This is, however, largely dependent on the material on the plastic part. Steel molds may be more expensive but they are compatible with various types of injection molding materials, complex designs, and provide manufacturers with great flexibility.

The mold class and the material play an important role in determining the injection mold lifespan. There are, however; various factors that affect the overall lifespan of an injection mold. Let’s take a look at some of the most important factors that can affect the lifespan of an injection mold.

The most important factor that determines the lifespan is the quality of the steel. Not only does the steel quality determine the mold life expectancy but also its performance. Thus, it’s imperative to select the right quality steel for your project. You should also note that the steel origin also determines the steel quality. For instance: Certified German and Japanese Steel is often regarded as high quality steel, due to their quality control. You will not get surprised batches of steel and can mostly trust its properties according to the certificate. Let’s take a look at some of the steel grades:

Mold classes are supposed to correspond to the maximum number of cycles a particular mold can operate, but not all of them last accordingly and one of the major factors behind that is the overall environment!

A clean operating environment that has minimal corrosive exposure can allow the mold to last for the longest time. You should note that molds that are used in very clean environments such as clean rooms can last even longer. On the other hand, if the mold is constantly exposed to harsh elements, debris, and dust, it will cause additional wear on the mold thereby, reducing its overall performance. Thus, the operating environment is one of the most important factors for mold classes. Not only does a clean environment influence mold life expectancy but it can also affect the production of plastic parts.

Injection molds are subject to wear and tear. This occurs particularly in ejectors, gates, slides, and other moving parts of the tool but it is also imperative that molds are set correctly in the injection molding machine. Some examples of incorrect settings are overlocking, poor tool alignment, excessive ejector stroke, and overpressurization of plastic material. These types of poor settings cause wear and tear of the mold which is why it is essential that the mold settings are handled by an experienced injection molder.

Plastic resins used in the manufacturing process also influence mold life expectancy. There is a wide array of plastic that can be used as injection molding materials and all of them have varying properties.

Some injection molding materials are more abrasive toward the mold than others. For example, Glass-reinforced plastics (GRP) or plastics such as acrylics, polycarbonates, and PVC. GRPs wear cavities and runners of the molds. Thus, a PVD coating i.e. physical vapor deposition is intensively used to improve wear resistance and increase the lifespan of the mold if, it’s necessary to use these types of plastics for the application.

While some injection molding materials are abrasive, others can be corrosive. Some materials can react to moisture or heat, and corrode the mold.

Injection molding materials also differ in terms of viscosity. Low-viscosity materials are thin and flow quickly, whereas high-viscosity materials are thick and flow slowly.

For e.g. Nylon has a lower viscosity than styrene and thus, is thinner and flows faster. Since low-viscosity materials are thinner and flow quickly, they are easier to fill in a mold than high-viscosity materials which are more resistant. Thus, more pressure needs to be applied with high-viscosity materials which can damage the mold.

You should note that impurities in molten plastic can also lead to mold degradation. Such impurities can alter the mold structure and additionally, the plastic part can also be affected by any type of corrosive or abrasive impurities. Thus, it’s essential to ensure that the manufacturing materials are free of impurities in the mold.

Production cycles create an extensive amount of heat and the mold has to sustain all the thermal stresses. The time gap between 2 production runs allows the mold to cool down before the next production run.

If an average time gap is maintained, thermal stresses can be contained to a sustainable level but if the same mold is subjected to continuous cycles, it may cause mold damage.

A high-speed production cycle can cause undue stress to the mold. On the other hand, a slower process causes less stress thus, it is important to factor in the production cycle time. Slow cycle times prolong injection mold life thereby enhancing durability.

You should note that the length of a production cycle time largely depends on the design elements such as wall thickness, and complexity. In addition, temperature control during the injection molding process also helps to lengthen the mold lifespan.

High-speed production cycles may be necessary for some situations but you should note that there is a higher chance of introducing defects in the mold. Additionally, faster settings that are used to speed production runs are another source of errors. If it’s not required, manufacturers should avoid fast production cycles as faster settings cannot only cause stress to the mold but they can also cause an error in clamping, premature opening of vents, and decoupling of pins.

Stresses are the highest at the ejection of the part in any injection molding process thus, the mold surface plays an integral role in determining the course of easy ejection of plastic parts. Many experts recommend PVD (physical vapor deposition) coating on the mold surface to facilitate a smoother ejection process. PVD coating is a deposit of an extremely thin, yet robust layer of metal-based particles over the surface and cavities of your mold. PVD makes tool material corrosion-resistant and harder. It also helps in ejecting and releasing mold parts.

Even if there is no PVD coating, it is imperative to keep the mold surface clean and smooth to ensure that there are no defects. This is a regular maintenance protocol for molds.

The design of the mold structure contributes to increased efficiency thereby increasing mold lifespan. Undue thermal stress is one of the most common causes of mold failure. Thus, it’s essential to consider design elements that can increase mold life expectancies such as vents, and push guides to facilitate plastic part ejection. These designs can help to reduce the overall stresses on the mold and allow it to last for a long time!

You should note that when molding components such as plates and cavities are constructed using high-grade steel, there is greater wear resistance as compared to molds made of inferior metals.

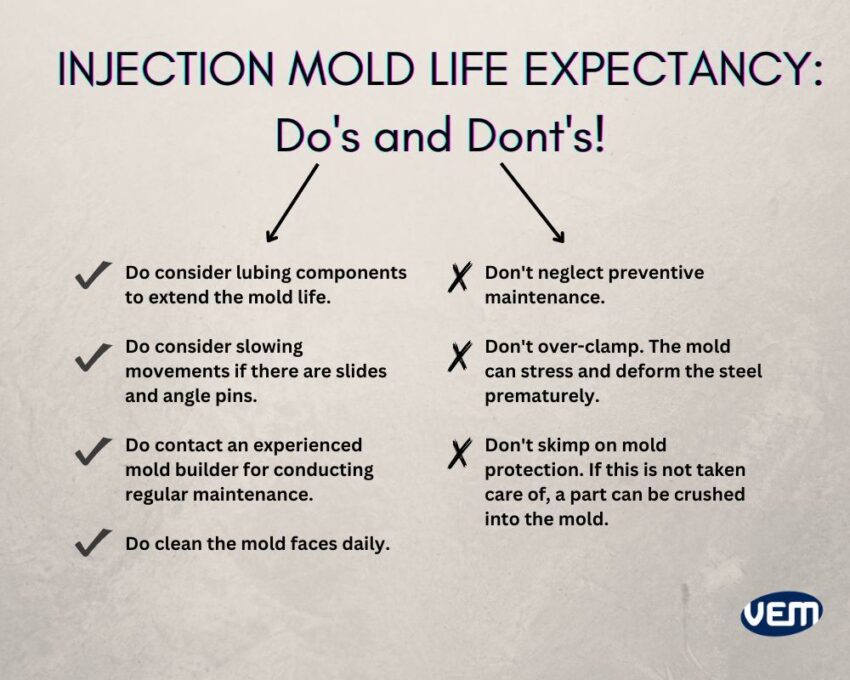

It’s important to implement an effective preventive maintenance protocol to ensure that injection molds reach their optimal life expectancy.

Since molds are an expensive investment in the tooling project, preventive maintenance saves resources. Thus, it’s essential to regularly inspect, clean, and repair molds. Mold maintenance is preventive and cost-effective. Preventive mold maintenance follows some of these practices:

Another factor that can influence mold life expectancy is the periodic cleaning of the mold. The exact cleaning and maintenance can vary based on the type of mold, but the most common activities include periodic cleaning, finishing, coating, and greasing of the mold.

The frequency of mold cleaning depends upon the resin type. For e.g. If glass-filled variants that are more abrasive are used, then mold cleaning should be more frequent.

Operating environments can be the cleanest and they may follow every protocol to ensure maximum mold life expectancy but they may not be optimized to deal with common defects.

Flow lines are way line patterns that appear on plastic parts that are usually caused by varying flow rates and it causes the molten plastic to solidify at different rates. This is generally fixed by adjusting injection speed and pressure in order for the cavity to be filled evenly or it could be a sign of bad mold design, in which case the mold must be redesigned.

Sink marks are commonly seen in plastic parts with crevices and are caused due to rapid cooling of one part of the mold. Such parts that have small craters or depressions become very difficult to eject and that can be inflicted on the mold, thereby damaging it and reducing its lifespan.

Burn marks are a common defect that is seen during high-speed production and occur due to excessive heating in some mold parts. Burn marks are extremely detrimental as they can render both the part and the mold useless.

Surface delamination can decrease mold lifespan by increasing wear over time. This defect occurs when the part splits into layers. It creates an abrasive surface that can damage the cavity or other parts of the mold during ejection.

Flash is a type of defect that creates extrusions when the molten plastic escapes the cavity. It is excessive plastic that comes out of the mold through the sides of the parting line. Flash causes mold clamp wearing (where extrusion occurs).

A mold with short life and insufficient preciseness affects the project investment and part quality. Mold life consistency depends upon various factors such as mold design, hot runner quality, the cooling effect of mold steel, and runner quality.

Let’s understand some of the do’s and don’ts for maintaining injection mold life expectancy:

If you’re sourcing an injection mold tool, you should check the exact guarantees that the mold maker has in place. Your manufacturer should cater to creating high-quality molds that are apt and suitable for the application. They should also guarantee a preventive maintenance schedule for your molds. An example is listed below:

A well-made tool may last an optimal time frame! It is possible that repairs may be needed, or parts may need to be reinforced, but if the mold tool is serviced and maintained properly, it can last to function well! You can look at a real example of a mold warranty here.

Molds are often the most expensive segment of any injection molding process. It’s imperative that the molds are not only built with high-quality material but also incorporate utmost consistency, precision, and durability.

Injection mold lifespan can be affected by various factors such as environment, materials, maintenance, molding conditions, and structure design. Injection mold life expectancy can be extended by making sure that the mold meets the part’s requirements, using appropriate operating conditions for the mold, periodic cleaning, and inspections, and using coatings for the mold.

The VEM tooling team has the expertise and experience with global manufacturers. At VEM Tooling, we ensure to build and deliver high-quality injection molds in the shortest time frame possible at competitive pricing.

It depends upon the application of your project!

Aluminum molds may be perfect for mold in some cases but soft aluminum molds are more prone to wear. They are also recommended for low-volume productions as they have the lowest life expectancy.

Steel mold is sturdier and far more durable. but it has some restrictions. They are often used for high-volume production and have an excellent lifespan.

Aluminum molds are cost-effective but they are not durable. Aluminum molds are recommended for short runs, prototyping, and for pre-production parts. If you are looking for a high volume production such as millions of parts, steel molds are recommended as they are more durable.

This is largely dependent upon the complexity of the design and the mold class but typically a steel tool costs anywhere from 20-30% more than an aluminum tool.

The timeline to build a molding tool depends upon the design complexity and the expertise of your molder. However; the general guidelines for building a mold tool are as below:

No, SPI classification is a standard for mold class that is guaranteed by the mold maker but there are various factors that influence the life expectancy of the mold. For instance: Class 101 molds from a good mold maker, can easily last 2-3 million shots under the right operating conditions.