Mexico has over 100 manufacturers that specialize in injection molding services. They are spread across various Mexican states.

We understand that the process of selecting injection molding companies in Mexico can be daunting and overwhelming, which is why in this article, we have enlisted every detail that you need to know about manufacturing in Mexico.

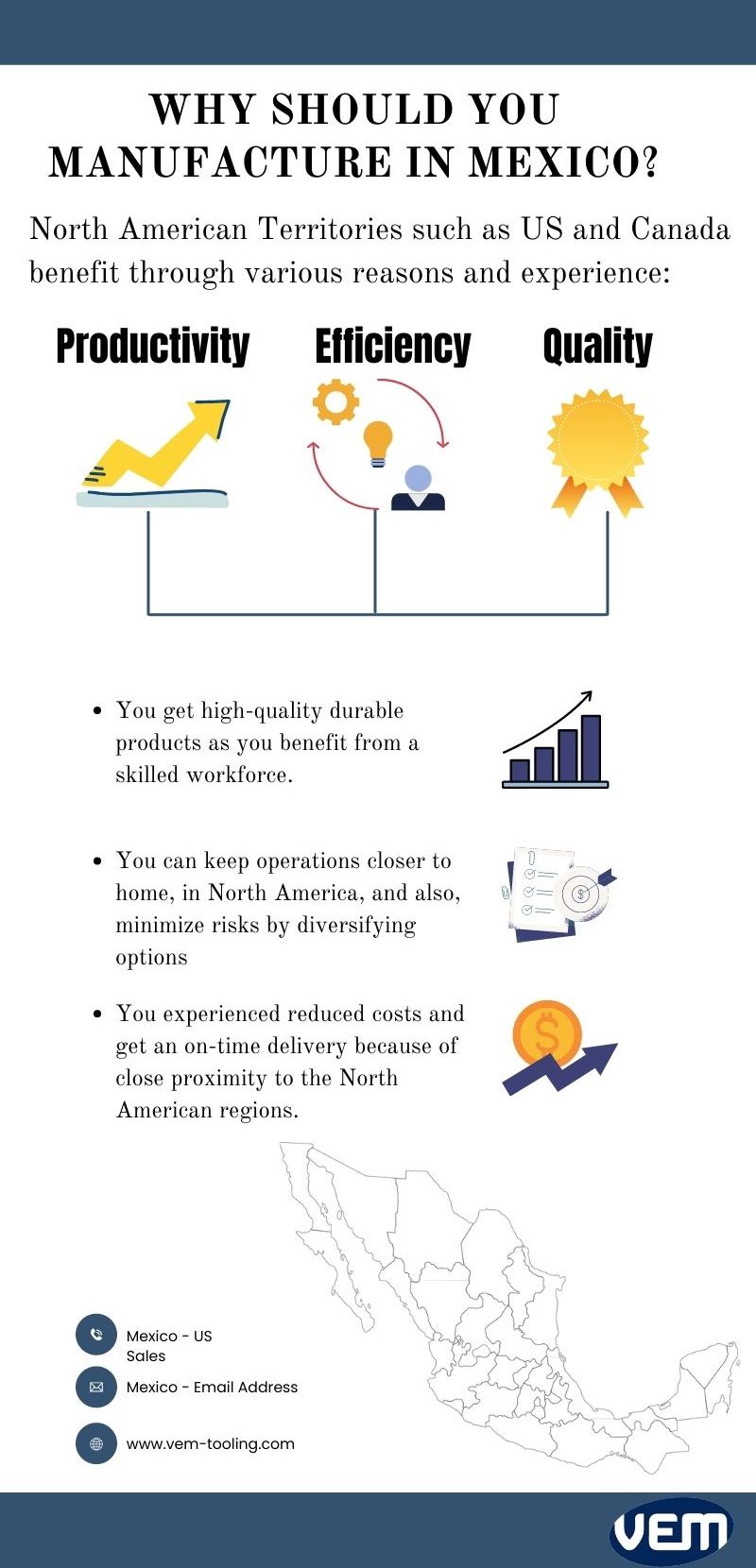

If you are in the North American territory, there are various benefits of moving your manufacturing to Mexico.

Manufacturing in Mexico is one of the most cost-effective options to maintain a North American manufacturing footprint. If you are seeking an alternative to China manufacturing, manufacturing in Mexico is one of the most viable options as it poses various advantages.

Proximity to the North American Regions: One of the most advantageous aspects of manufacturing in Mexico is proximity to the North American territories. While that may be obvious, manufacturing in Mexico adds to the benefits in the form of time zone compatibility and therefore, increases communication and productivity.

Reduced Labor Costs: Manufacturing in Mexico is just as advantageous as manufacturing in China. It reduces labor costs just like the way manufacturing in China does, but in addition, you also get to maintain a North American manufacturing footprint. It is also important to note that labor costs in Asia, especially China, have been rising for a few years now, which is why manufacturing in Mexico is proving to be more competitive.

Reduced Transportation Costs: Maintaining a North American manufacturing footprint can be exceptionally advantageous as it helps to significantly reduce transportation costs. They are generally, quickly nullified by the transoceanic shipping cost if that is incurred by manufacturing in China.

Shorter Supply Chains: In addition to reduced transportation costs, North American companies have the benefit of a shorter supply chain, if they choose to manufacture in Mexico. Urgent orders can easily be shipped via cargo trucks as opposed to air delivery if they were being shipped from Asia or the Middle East.

Skilled Workforce: The Mexican workforce is talented, skilled and has strong work ethics. Over the past few decades, they have continually performed complex tasks in the injection molding industry for the automotive, electronics, medical devices, consumer goods, aerospace, and other industries.

Duty-Free Access: Mexico has twelve free trade agreements that let companies benefit by doing duty-free business with major nations. These include USMCA, IMMEX as well as similar arrangements with the countries of the European Union and Japan.

Protection of Intellectual Property: One more advantageous aspect of manufacturing in Mexico is that you can ensure that your IP is protected since manufacturing companies in Mexico have similar IP laws as to those that are found in the United States and Canada.

Easy Access: Due to close proximity to North American territories, Mexico factories are easy to access. You can also conduct factory audits and work on projects together. The connectivity is easy, as there are many direct flights operating from the United States.

Government-regulated Industrial parks: One of the great aspects of manufacturing in Mexico is that most of the industrial parks are government regulated which is why they are very advanced and have great infrastructure.

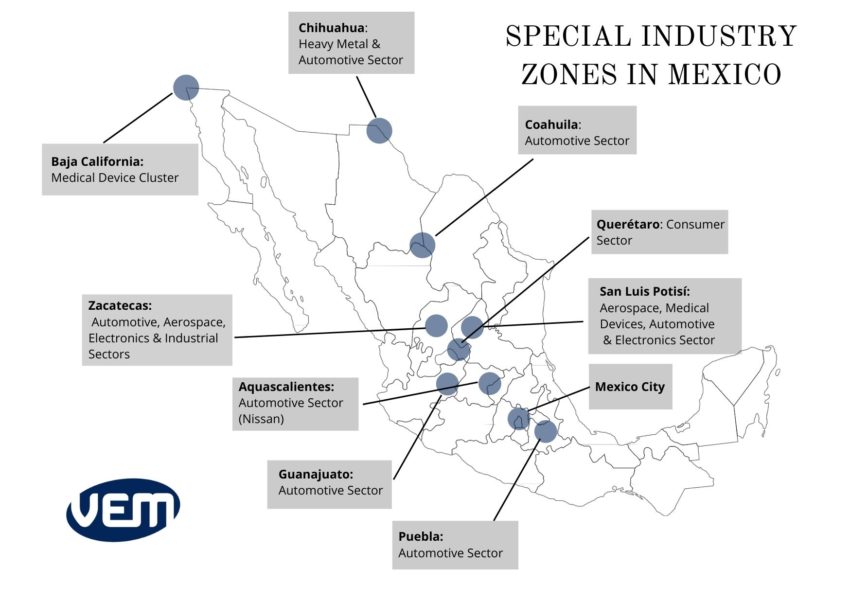

Mexico offers the best manufacturing practices for various industries. Some of the most common sectors that run their manufacturing in Mexico include:

The above list is only inclusive and enlists simply a couple of the major industries that choose to manufacture in Mexico. Companies get to leverage a skilled and motivated workforce which includes engineers, supervisors, and professionals if they choose to manufacture in Mexico.

The following infographic is indicative of major manufacturing clusters in Mexico:

Free Trade agreements with Mexico offer various benefits to companies seeking to manufacture in Mexico.

Free trade agreements, commonly abbreviated as FTA’s encourage global competition by providing countries access to different markets. FTA’s helps to reduce barriers between countries so that they can trade more easily. It does so by increasing co-operation between the countries.

The primary goal of FTA is to promote business opportunities and boost the country’s GDP. FTAs also provide various benefits to companies seeking to manufacture in foreign countries which is why it is synergistically beneficial.

Mexico is a member of the World Trade Organization (WTO) and has 14 FTAs with 50 countries. These include trade agreements such as USMCA and FTAs with the European Union, Japan and more.

Since Mexico has a total of 14 FTAs with more than 50 countries, it easily garners access to over 60% of the world’s gross domestic product. You must note that uniform tariffs are applied to countries that trade but are not a member of the FTA. If not a member, the tariffs are generally applied on a case by case basis and this is set by a third-party source, usually the World Trade Organization.

USCMA or CUSMA is a free trade agreement between the United States of America, the United Mexican States, and Canada.

It is commonly known as USMCA (United States–Mexico–Canada Agreement) in the United States and CUSMA (Canada–United States–Mexico Agreement) in Canada. These agreements were previously known as NAFTA and today, are sometimes also referred to as, NAFTA 2.0 or New NAFTA.

The New NAFTA agreement is mutually beneficial and supports North American farmers, ranchers, workers, and businesses. Its primary goal is to protect U.S. intellectual property and encourage trade opportunities in U.S. services.

You can view the agreement highlights here and details of the complete agreement, here.

IMMEX was also previously known as the IMMEX maquiladora program. The IMMEX program is a tax and duty-free program that aids end -to -end manufacturing in Mexico. This program enables foreign manufacturers to import raw materials into Mexico with the condition that the finished goods will be exported only out of Mexico and within a government-mandated time frame.

The motto of the IMMEX program is to enable foreign companies to manufacture in Mexico, which in turn creates jobs and thus, helps to expand the Mexican economy.

IMMEX also aims to encourage globalization and modernize Mexico’s manufacturing standards by bringing in the latest and specialized technologies to the region. You can view details about IMMEX certification and permits, here.

EU-Mexico FTA is a comprehensive free trade agreement between Mexico and Europe. This trade agreement enables both the regions to gain preferential access to goods and services.

In April 2018, both Europe and Mexico reenacted a new trade agreement that encompassed a broader global agreement. In this trade agreement, almost all the goods are practically duty free.

This trade agreement favors various industries such as the agricultural sector, pharmaceuticals, machinery and transport equipment. You can read more about the EU-Mexico FTA agreement here.

VEM Tooling Mexico manufacturing facility is located in Querétaro, near Mexico City. It is approximately 135 miles / 218 kilometers away, from Mexico city so you can reach the facility via, road within 3 hours.

We have a team size of 30 people that includes designers and engineers, with a vast experience in producing custom plastic parts.

We source molds from our mold making facilities in Bulgaria, China and India and currently, have 14 injection machines at the Mexico facility. VEM Tooling Mexico facility also provides equipment for mold repair & maintenance.

VEM Tooling’s Mexico manufacturing facility is an integral partner of various global leaders such as Safran, Kemeny, ISI, and more.

You can view more details about VEM Tooling’s Mexico facility here and also, book a tour with us if you are in town.

VEM Tooling’s plastic injection molding facility in Mexico is dedicated to providing you with exemplary service. In addition, our US-based sales team in California, Michigan, Arizona, Texas and New Jersey, can help you to optimize tariff costs and streamline your plastic manufacturing in Mexico.

We ensure that you have a great experience from start to finish. You can contact us to further understand the benefits of manufacturing in Mexico and learn how our injection molding facility in Mexico can solve your manufacturing needs.

To better understand how VEM tooling can serve you, for your manufacturing requirements in Mexico, contact us or request a quote today.