Injection molding is a manufacturing process for the mass production of simple or complex plastic parts in huge quantities. The primary advantage of injection molding for a project is its ability to scale production. In the case of injection molding, the production costs tend to dramatically decrease as more plastic parts are produced.

Injection molding can often be perceived as daunting if correct guidance or right information isn’t available. In this article, we have enlisted injection molding details for any project.

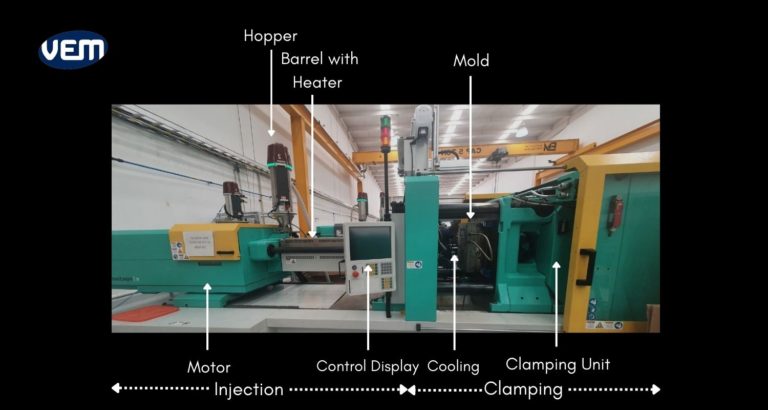

An injection molding process for any project consists of 3 components and 2 sets.

The 3 components are as follows: plastic resins, an injection molding machine, and a mold.

The 2 sets are as follows: Injection and Clamping

Injection molding machines are usually laid out horizontally. The following image illustrates the sets and components of an injection molding machine:

Injection molding is carried out by first melting the plastic resins in the injection unit. The melted plastic is then injected into a high-quality steel mold. The plastic cools here which is then solidified into the final plastic part. The following entails injection molding steps that ensure that the process is smooth and seamless:

There are certain guidelines that should be adhered to in order to ensure that the plastic parts manufactured are of the required quality.

The following list includes a checklist of such parameters:

Here are some basic inquiries that must be made while approaching any injection molding project:

The following queries can help you understand the reliability of the injection molding company:

Imidized materials are high-performance plastics with high resistance to steam, chemicals, and temperature. The most notable feature of imidized plastic materials is that it has a high resistance to temperature. Imidized materials are usually considered for high-temperature applications of 500℉. We have listed below imidized materials:

Advanced engineering materials are plastics that are specifically engineered to exhibit enhanced properties. They are manufactured to include superior performance over other plastics. Some examples of advanced engineering materials are as follows:

Engineering plastics are designed to withstand extreme environmental conditions and thus, have better mechanical and thermal properties than other commodity plastics. Some examples of engineering plastics are listed below:

Standard plastics are general-purpose plastics. They have good bonding and great formability but they have a low-stress resistance as compared to the other plastics. Some examples of standard plastics are listed below:

Today, injection molding is one of the most preferred processes for mass-producing plastic parts due to its high output rate and consistency of quality. It can be applied to a multitude of daily use products such as:

The above list is only inclusive and not limited. Injection molding can be used to make a wide array of products across various industries.

VEM Tooling encompasses an extensive experience in injection molding plastic parts. If you have a query regarding a project about injection molding, please feel free to reach out to us. We would like to understand the task at hand and provide you with any guidance.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.