PP, abbreviated for Polypropylene, is a type of plastic polymer that is known for its tough and flexible properties. It is thus, one of the most popular material choices for manufacturing in injection molding.

An interesting anecdote in the manufacturing industry is that polypropylene plastic is often referred to as the ‘steel’ of the plastic industry. It is said so, because it can be customized in various ways to manufacture various products.

This article provides an in-depth analysis of how polypropylene can be used for injection molding. In this article, we discuss what is polypropylene? Its properties, its applications and whether you should consider polypropylene plastic for your projects?

Polypropylene is also known as polypropene and is commonly abbreviated as PP.

PP plastic has been used to manufacture plastic parts in an array of industries that range from consumer products, and medical devices to plastic components in the automotive industry.

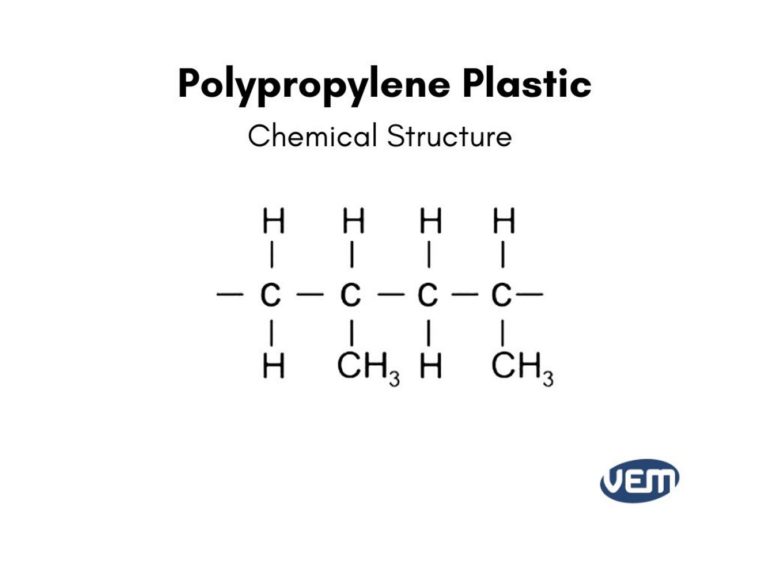

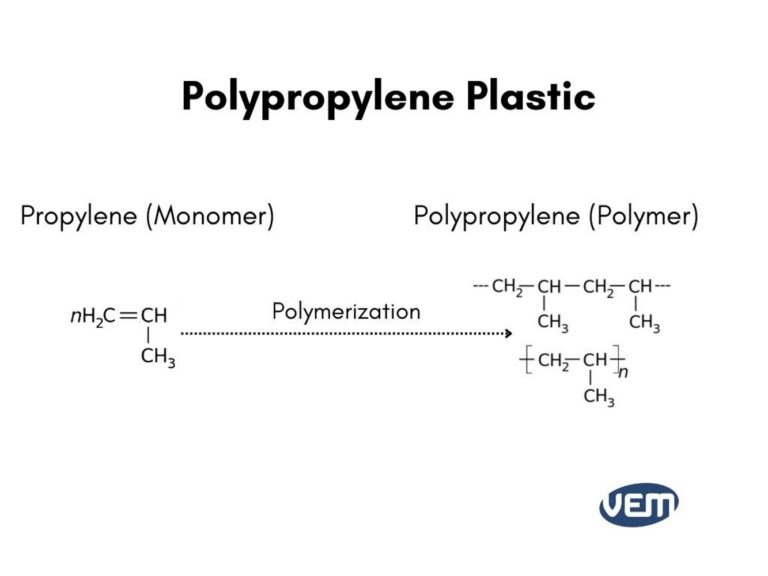

Polypropylene plastic is a type of thermoplastic polymer that is produced through chain-growth polymerization of the propylene which is a monomer. It basically is a thermoplastic polymer made by combining several propylene monomers.

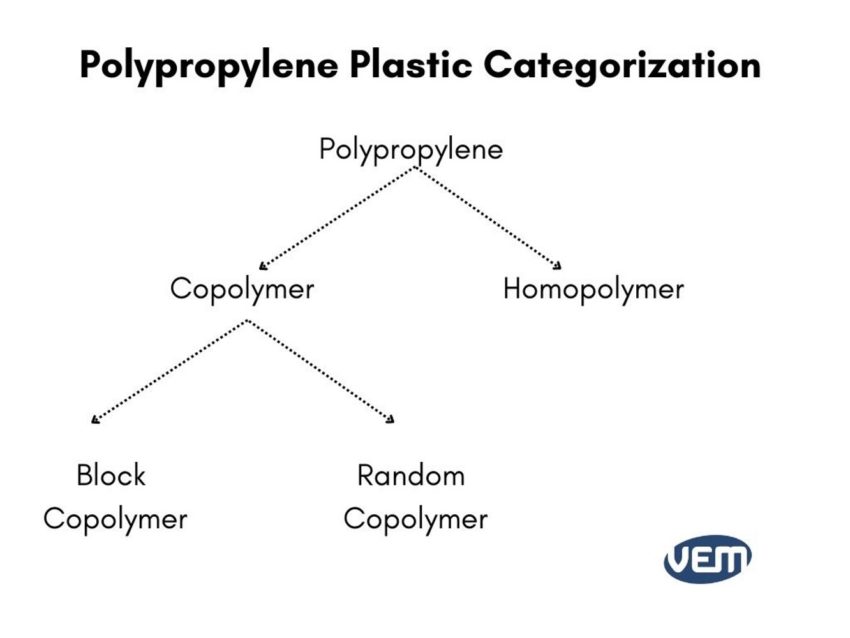

Polypropylene plastic is further categorized into 2 different types. These are known as homopolymers and copolymers. The copolymers are also of 2 types: block copolymers and random copolymers. The below diagram illustrates the categorization of PP plastic:

It’s important to understand the different types of PP plastics as each of these categories can be applied to one application better than the other. You should also note that polypropylene plastic is highly adaptable and this is usually achieved by introducing special additives to it or by manufacturing it in a very particular way.

Let’s understand them in-depth:

3D Printing Polypropylene: PP plastic is not available in its filament form for 3D printing.

CNC Machining Polypropylene: In the case of CNC machining, polypropylene is widely used as sheet stock for manufacturing via CNC machine. You should note that typically, CNC machines are used to prototype a small number of polypropylene parts. This is because it is assumed that PP plastic cannot be machined due to its low annealing temperature. Since it’s a soft material, it requires an extremely high skill level to be cut with precision.

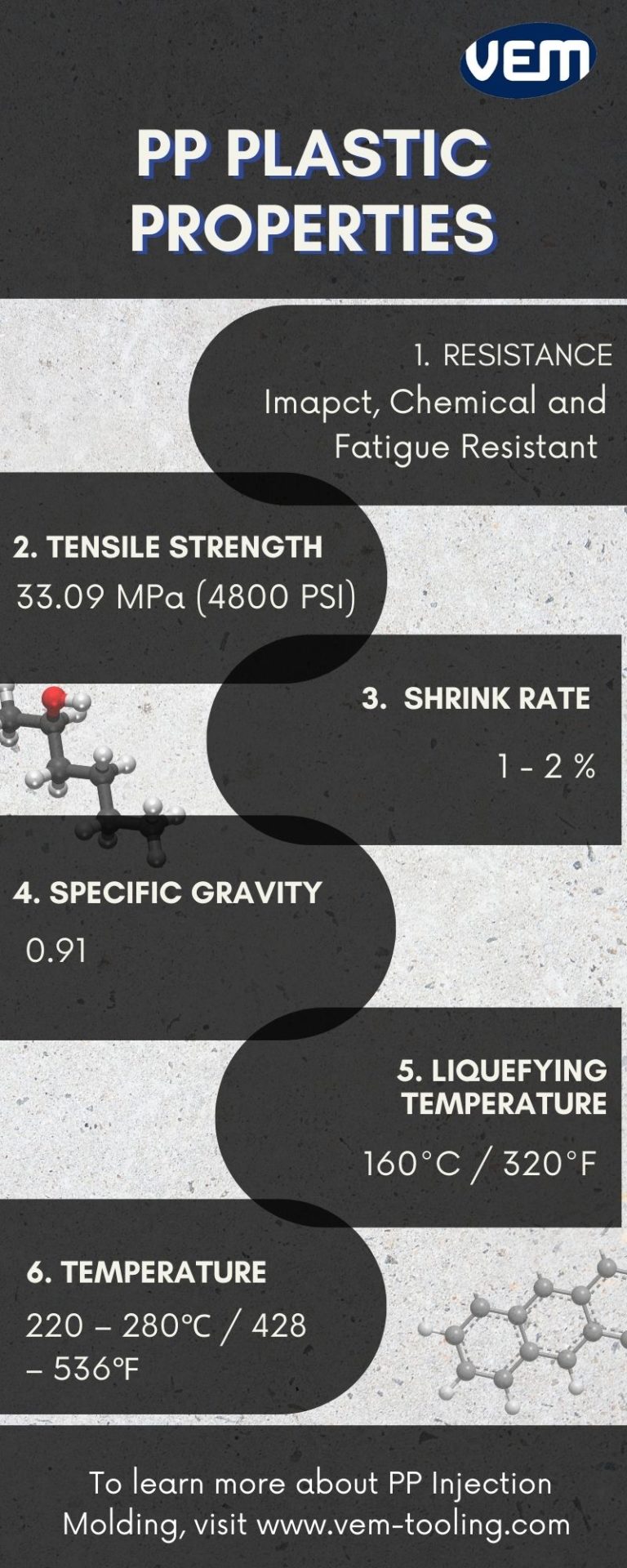

Injection Molding Polypropylene: PP is available in the form of resins or pellets for injection molding. It’s easy to mold and it flows well within the mold because of its low melt viscosity. It’s important to also note that PP plastic shrinks at a rate of about 1-2% but this factor can vary and is dependent upon a number of factors such as holding pressure, melt temperature, mold wall thickness, mold temperature, and the type of additives.

The next factor that your manufacturer should ensure is the injection molding speed. If the injection molding speed is high, it can cause burning or thermal decomposition of the plastic material. It can also cause poor glossiness, discoloration and weld lines in the plastic material.

On the other hand, if the injection molding speed is too slow, insufficient mold filling will occur which can result in other types of defects in the injection molded part.

PP Plastic can be applied to various medical applications. PP is generally resistant to strong chemicals and steam sterilization which makes it ideal for manufacturing medical supplies. It is often used to create petri-dishes, syringes, specimen bottles, pans, vials, and pill dispensers. For insights in this industry, take a look at our medical device industry page.

Polypropylene plastic is affordable and easy to mold, and is thus, very popularly used to manufacture plastic parts for the automotive industry. These automotive parts can range from car battery cases, dashboards, and instrument panels to door trims, and more. Another common material for automotive parts, is the heat resistant POM (Polyoxymethylene).

Polypropylene is very popularly used for the production of consumer products. Since PP plastic is durable and resistant to high temperatures, it’s an ideal material for kitchen and home appliances such as washing machines and coffee makers. Apart from home and kitchen appliances, PP plastic can also be used to manufacture toys, furniture, carpets, and mats, to other consumer products. PP products from the consumer industry are the easiest do recognize in your daily life.

PP film is known for its strength and resistance against tears, punctures, and high temperatures. It is thus, one of the most popular plastics for industrial parts.

PP Plastic is available in various forms that can range from resins, rods, films and sheets. We have listed some of the leading suppliers for PP Plastic:

LyondellBasell is a US-based company and is a global manufacturer for PP plastic.

Braskem is a leading producer of propylene in the US and other global markets. Along with PP, they also manufacture ethylene, naphtha, polyethylene, etc.

China Petrochemical is a part of the Sinopec Group and is an oil and energy company. They have a wide array of polypropylene products to choose from.

Exxon Mobil excels in gas and oil exploration. It’s a global company and is present in 21 countries. Exxon Mobil manufactures PP packaging films and along with that, it is also known for manufacturing olefins, aromatics, fluids, synthetic rubber, and polyethylene.

GE Plastics cater to global industries. They have various grades of PP resins that the manufacturers can buy to develop their products.

Cheil is a Korean based company and it produces PP resins that can be used to produce quality plastic parts for various industries.

Dow is a US-based based company that provides approximately 100 types of PP resins, it is also popular for ABS resins.

VEM Tooling has the expertise for your PP injection molding project. At VEM Tooling, we offer a dependable service with quick quotes. We ensure that you have a great experience with a seamless manufacturing process.

To better understand how VEM tooling can serve you for your PP injection molding project, contact us or request a quote today.