Psychology has demonstrated that the look and feel of the product directly affect brand perception, and high-quality labels impart immense value to product design. They instantly elevate the brand value! Thus, you really need to pay attention to the label and its design. One of the most effective processes to get high-quality labels is via in-mold labeling.

In-mold labeling was first introduced in the 1970s by Owens-Illinois along with Procter & Gamble, and they first applied the technique to pre-labeled bottles. Today, it is one of the most popular techniques that is used by various industries.

In-mold labeling is a distinct and unique technique that is applied to create high-quality, colorful labels in plastic parts. It’s a cost-effective technique that helps to enhance the design of the product. In this article, we explain the various aspects of in-mold labeling extensively.

In-mold labeling, abbreviated as IML, is a type of labeling process in which a pre-printed film (i.e. the label) is placed into a mold before the part takes its shape into the mold. Through this process, the label is imprinted on the part and it emerges from the mold as a single product. The preprinted label is inserted via automation into the mold cavity and then, the molten plastic is fused with or injected over the label.

In-mold labeling technology enables seamless fusing of the label to the thermoplastic material during the molding process itself thereby, integrating the production with the labeling process. This eliminates the process of post-labeling. You should note that after curing, the label and part become a single waterproof and scratch-resistant piece.

In-mold labeling is commonly applied to thin-walled disposable items such as in consumer and cosmetic industries. Some of the most common examples are ice cream tubs, butter boxes, and skin creams.

IML has various advantages over conventional labels such as providing greater flexibility, creating aesthetically appealing parts, and being environmentally friendly as now, only a single plastic needs to be recycled.

There are various processes that are often used as alternatives to in-mold labeling. Let’s take a look at some of the labeling solutions:

Metallized labeling solutions make use of light and durable metals such as Aluminium and offer a very premium look. In metal labeling solutions, a microscopic thin layer of the metal is evaporated on paper and applied to the container.

Metal labels work with a majority of inks, and have excellent printability along with text clarity.

Wet strength labels are able to withstand high moisture conditions and they are thus, popularly used in the beverage industry. They are compatible with nearly all printing technologies and are tolerant to high and low temperatures as well as humidity.

Pressure-sensitive labels are one of the most common labeling solutions as they offer high quality and are compatible with all types of printing techniques. They are able to withstand oxidation and moisture to an extent.

Labels created through laser marking are particularly used in the automotive and electronic industries. There are various advantages of laser marking techniques such as they have a high level of resistance, they cannot be replicated so they are anti-counterfeit and they are highly flexible with respect to design.

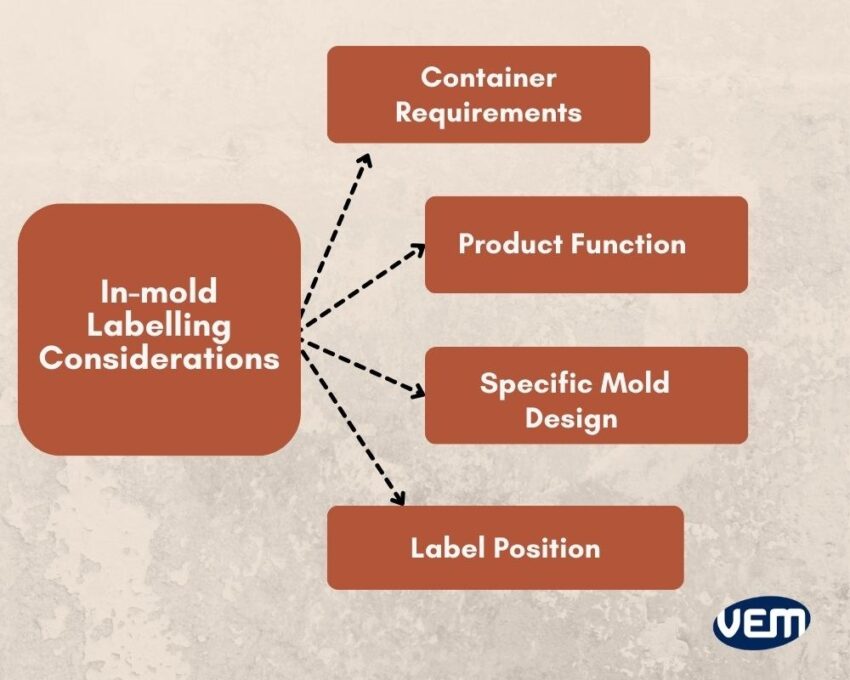

In-mold labeling technique has various advantages however; there are some considerations that you should account for in order to understand if the in-mold labeling technique is the right labeling technique for your project. Let’s take a look at these considerations:

The first consideration should be to understand the requirement of the container with respect to its shape, color, size, and surface consistency. These questions help the label suppliers to determine the type of label for the container.

It’s crucial to note the function of the product as it helps to understand other factors that can influence the decision of the label as well. The product could require to be under fluctuating temperature environments, or it may need special coating chemicals, or it may require freezer grade, autoclave, or ultra-clear resin. All these functions should be noted to make the best-informed decision.

The next consideration should be the position of the label. This is an important factor as the positioning of the label helps to avoid any type of distortion that might occur to your design.

In-mold labeling techniques require a specific mold design thus, this should be considered when choosing an in-mold labeling technique.

In-mold labeling can be applied to a wide range of products of various industries. Let’s take a look at some of its popular applications:

There are various in-mold labeling processes. In this section, we take a look at some of the top in-mold labeling processes.

Injection molding is one of the most common and accepted technologies for in-mold labeling of thermoplastics and thermosetting polymers.

In this process, the molten resin is injected into the mold and allowed to cool and solidify. In the case of the injection molding technique, the pre-printed label is placed into the mold cavity. When the molten resin solidifies, the label seamlessly fuses with the thermoplastic to form a single product.

Blow molding is just like injection molding, where the label is inserted into the mold before it combines with the plastic. Blow molding was originally used to manufacture glass bottles but today, this technique extends to plastic bottles and in-mold labeling techniques.

The blow molding in-mold labeling technique is further classified into extrusion, stretch blow, and injection blow molding.

In the case of blow molding, the molten resin is blown using an airstream instead of injecting it into the mold. The heated plastic mass either stretches or extrudes to take the mold shape and the pre-printed label melds into the container, once it expands into the desired shape.

The fusion of the label with the container occurs when the glue on the label’s surface is activated due to the heat of the resin. This technique is often used to manufacture and label hollow plastic parts such as liquid containers for shampoos, dishwashing detergents, and sauces.

In the case of thermoforming, heated plastic sheets are used and the plastic does not melt completely. The heated plastic sheets are shaped to stretch around a forming tool which then takes the mold shape after which the plastic cools to solidify. In this process, preprinted labels accompany the plastic sheets, and a forming tool gives the plastic sheets the container form.

The heated plastic sheets are stamped onto a mold and at this stage, the pre-printed label fuses with the plastic sheet. Thermoforming is often used for rigid plastic packaging. Some examples of in-mold labeling via thermoforming are printed plastic cups and tubs for ice cream.

In-mold labeling offers significant advantages to the product and the entire production process. Let’s take a look at these reasons:

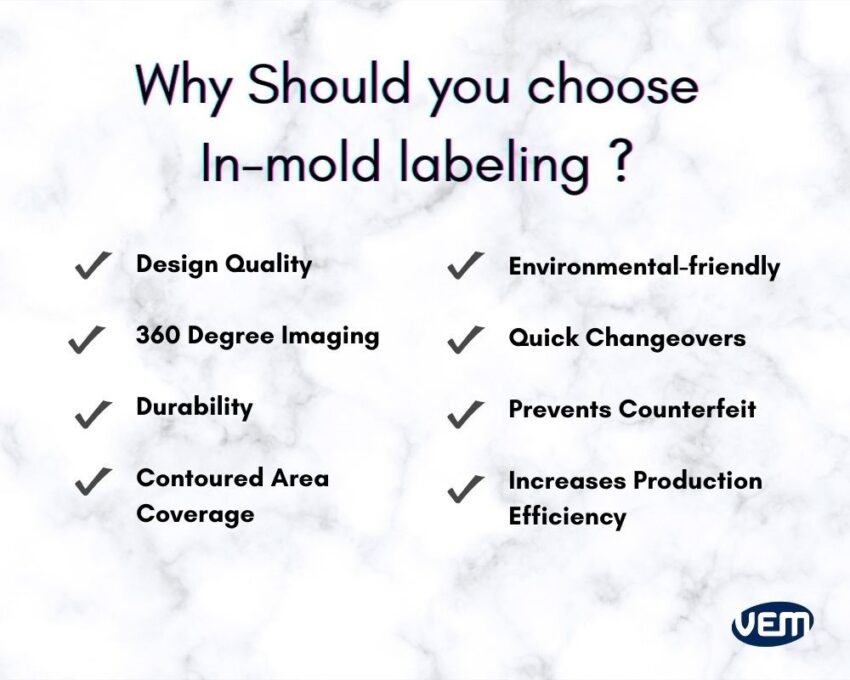

In-mold labeling techniques significantly improve the design quality by improving the labels of the product. It gives the product a clean, smooth, and integrated label. These types of labels remain intact and are tamper-proof, unlike post-mold labels.

In-mold labeling offers a powerful platform for manufacturers and designers to enhance graphic effects. This technique offers high resolution in colors and is compatible with a wide array of colors. It also enables the flexibility to include various types of creative designs such as flat, curved, and 3D-formed graphics.

Since in-mold labels are not limited in size or coverage, they enable product owners to create powerful visual statements with the help of labels. This is especially helpful for consumer goods where the brand image and product story can be illustrated vibrantly on the container.

In-mold labels are highly durable as they are water resistant, and can withstand both, humid environments and extreme temperature fluctuations. Since in-mold labels permanently fuse to the container, they demonstrate excellent impact, abrasion, and scratch resistance. In addition, in-mold labels are generally impervious to chemicals and are waterproof, oil-proof, and mildew-proof.

In-mold labeling technique is environmentally friendly as both the label and the container are combined together. You should note that traditional methods such as pressure-sensitive labeling require various types of adhesives that are not considered eco-friendly.

In-mold labeling containers are completely recyclable and thus, help to decrease the carbon footprint!

In-mold labeling makes use of uniquely designed molds that require expertise and high costs which is one of the factors that prevent fraudulence. In addition, the in-mold labeling technique offers a wide array of variations with respect to mold design and film printing thereby making it impossible to copy products and thus, helping to preserve the brands.

Stick-on, adhesive labels or pressure-sensitive labels cannot cover contoured areas of containers as they can’t accommodate curved surfaces of the molded parts. In contrast, the in-mold labels are able to provide a seamless coverage that can cover all the contoured areas of the container.

Since the containers are manufactured and labeled at the same time, it increases the production efficiency by significantly reducing the production time and cost. Thus, incorporating in-mold labeling significantly improves efficiency and production.

In-mold labeling offers quick changeovers as there is no extra cost associated with changing the label packaging. If a new design is incorporated via in-mold labeling, there is typically no to very little production loss during the change.

If you’re interested in in-mold labeling solutions, our team can help you design and create optimum retail packaging. At VEM-Tooling, we have a team of design experts and engineers who can help you choose the right solution for your project! Our team has vast experience in manufacturing solutions including in-mold labeling services.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.