H13 tool steel is a durable and a versatile choice for applications that require high-temperature settings. It belongs to the category of hot-working steels and demonstrates an exceptional combination of high hardness, and excellent resistance to heat, abrasion and stress.

In this article, we discuss the various characteristics and specific attributes of H13 tool steel and why it is a popular steel of choice in manufacturing and industrial applications.

H13 steel is a versatile chromium-molybdenum steel that demonstrates an excellent resistance to thermal shock and heat cracking. It also exhibits high wear resistance, good mechanical properties and machinability. H13 tool steel comprises higher vanadium content which contributes to the increased heat resistance.

H13 steel is an air hardening chromium die steel that is employed for various applications. It’s one of the most popular steel grades for various industries and can be applied for both hot work and cold work tooling applications.

Thermal fatigue cracking is a common occurrence in hot work tooling applications as a result of continous heating and cooling cycles. H13 tool steel demonstrates an excellent resistance to thermal fatigue cracking as it combines high toughness and hot strength or hardness.

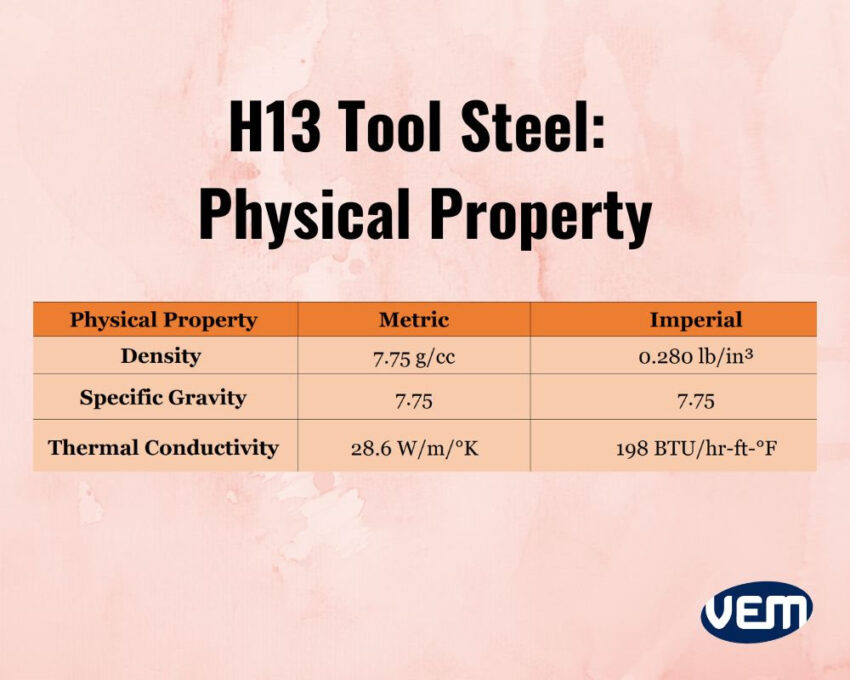

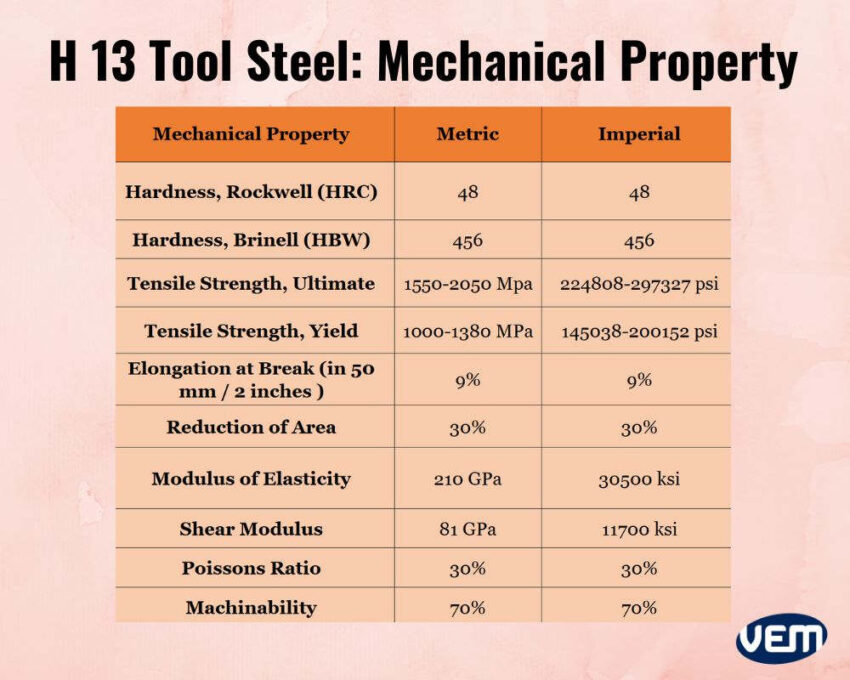

H13 tool steel demonstrates excellent physical and mechanical properties such as high hardness level, good abrasion resistance at both low and high temperatures, good thermal conductivity and ductility.

H13 tool steel is an extremely strong steel. It demonstrates a high level of toughness, strength and hardenability. You should also note that during hardening, there is very limited distortion in H13 steel.

H13 tool steel demonstrates a high level of uniform machinability. It also demonstrates good polishability.

If H13 steel is exposed to high temperatures, loads or extremely corrosive environments, its surface can wear down quickly. To overcome this limitation, H13 tool steel is often nitrided via gas.

H13 tool steel has a high level of hardness but its toughness isn’t ideal. During quenching, the internal stresses can lead to the cracking of the mold if the mold isn’t released in time. This can be avoided by tempering the H13 steel 2–3 times at a high temperature.

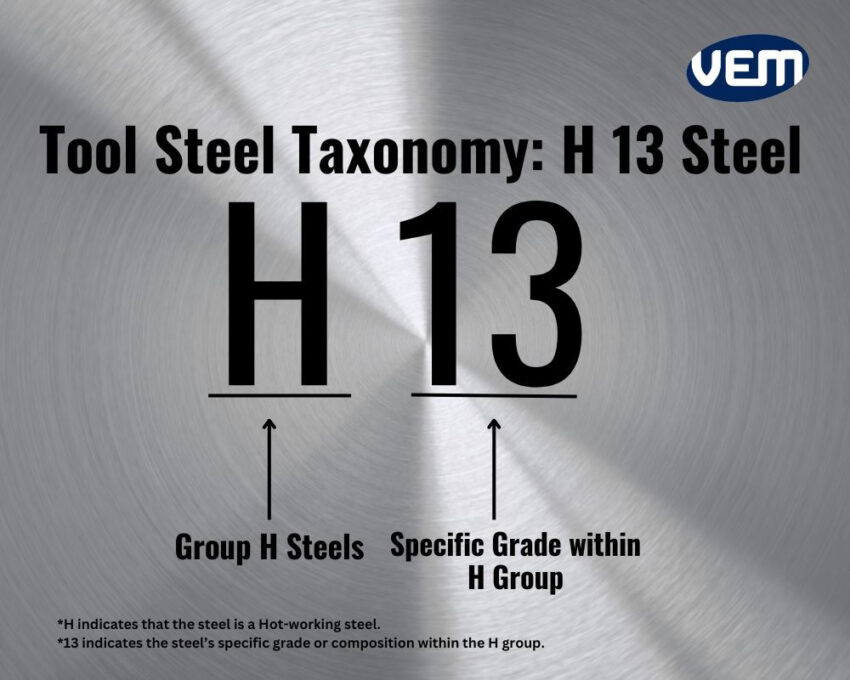

Mold steel is jointly labeled by 2 groups in the United States: AISI, abbreviated for the American Iron and Steel Institute, and SAE, abbreviated for the Society of Automotive Engineers.

Together, AISI and SAE have developed a steel grade numbering system referred to as UNS, abbreviated for Unified Numbering System. The UNS for H13 Tool Steel is UNS T20813.

AISI classification system denoted the letter ‘H’ to categorize a particular set of mold steels i.e. ‘Group H’ steels. All steels that are designated with the letter H are hot work steels and the main alloying elements in these mold steels are Chromium, Vanadium and Molybdenum. The H group of steels includes steels from H1 to H19.

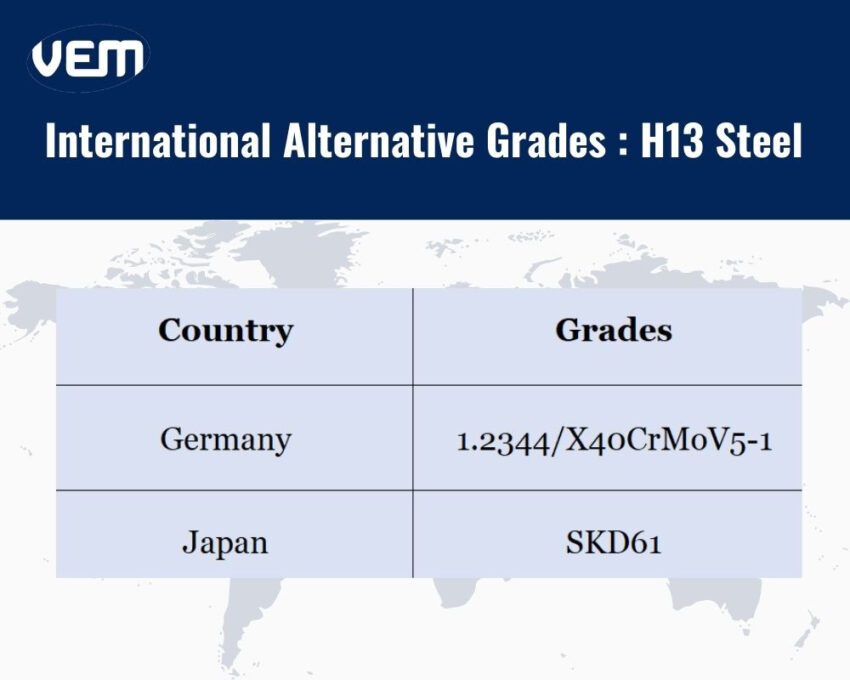

H13 tool steel is a popular hot-working tool steel and it has similar grades, available internationally. These grades are not H13 steel but they are similar in element and composition which makes it imperative to comply with the standards of the country. The equivalent grades of AISI H13 tool steel in Germany and Japan are listed below:

H13 tool steel is a popular hot-working tool steel. It demonstrates a high level of ductility, toughness and durability.

H13 tool steel has excellent mechanical properties. It is easily machinable and has good abrasion resistance. It also demonstrates good polishability and excellent hot-wear resistance.

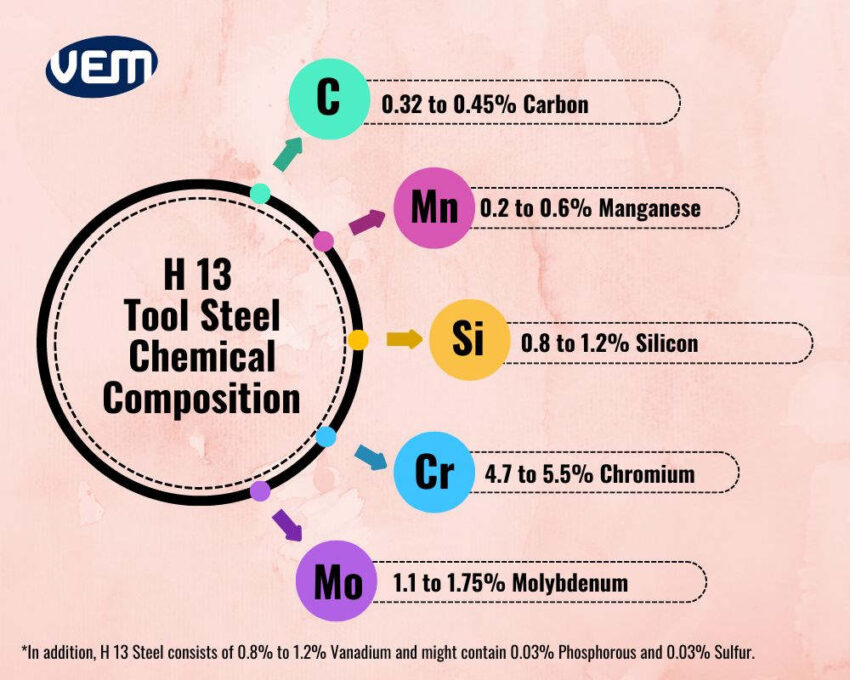

The chemical composition of AISI H13 tool steel consists of 0.32 to 0.45% Carbon, 0.2 to 0.6% Manganese, 1.1 to 1.75% Molybdenum, 0.8 to 1.2% Silicon, 0.8 to 1.2% Vanadium, and minute quantities of Phosphorus and Sulfur as impurities.

This particular chemical composition of H13 tool steel imparts the steel with excellent properties. The vanadium and molybdenum strengthen the steel while the high chromium content prevents the steel from softening at high temperatures.

If the tool steels are directly heated for heat treatment processes such as austenitizing, it can lead to thermal shock. Preheating reduces the risk of cracking and warping that may be caused due to thermal shock. In the case of H13, the tool steel is first preheated to 816°C / 1500°F and then the temperature is instantly raised to 1010°C / 1850°F which is then holded there for 15 to 40 mins. The steels are then air-quenched.

Annealing is a type of heat treatment process which makes the tool steel ductile and easier to work with. In the case of H13 tool steel, the annealing is carried out at 871°C / 1600°F which is then slowly cooled at 4°C / 40°F in the furnace. You must note to ensure precautions to prevent excessive carburization or decarburization.

Austenitizing is rapidly heating the steel at high heat, directly after pre-heating. This heat treatment process transforms the microstructure of the steel. In the case of H13 tool steel, the steel is heated between 982-1032°C / 1800-1890°F in a furnace or salt.

Hardening helps to balance the steel’s toughness. H13 tool steel is preheated to 780-820°C / 1436°-1508°F in a surface and then it is subjected to the final hardening temperature of 1000-1030°C / 1832°-1886°F. It is soaked in this temperature for approximately half an hour.

Stress relieving is a type of heat treatment process that is carried out to reduce internal stresses. This heat treatment process can be carried out after subjecting H13 steel to any high temperature heat treatment procedure. In the case of H13 tool steel, stress relieving can be carried out by slowly heating the steel between 565-676°C / 1050-1250°F which is further, equalized and air-cooled.

H13 tool steel can be quenched through various quenching mediums such as air, oil, water, pressurized gas or polymer solutions. H13 steel can be quenched at 500-550°C / 932°-1022°F.

If the section thickness is either at or up to 127 mm / 5 inches, it can be air cooled. However; if the section thickness is greater than 127 mm / 5 inches, then the cooling will need to be accelerated through pressurized gas, or an interrupted oil quench to achieve maximum hardness, toughness and resistance to prevent thermal fatigue cracking.

H13 tool steel is tempered directly after quenching to increase the toughness of the steel and relieve any type of internal tensions. The steel is reheated to a certain temperature range, and maintained there to lower the steel’s hardness and improve upon it’s toughness. This particular process is known as tempering.

In the case of H13 tool steel, the usual tempering range is between 500 to 650°C / 932 to 1202°F to obtain a hardness level of 53 to 38 HRC.

H13 tool steel demonstrates good machinability. The machinability rate is between 70-75%.

Forging involves applying localized forces such as pressing and hammering to shape the steel. H13 tool steels can be forged at a temperature of 1079°C / 1975°F. You should note that H13 steel shouldn’t be forged below 850°C / 1562°F. After the forging, the H13 tool steel must be gradually cooled in a furnace, lime, or mica.

H13 tool steels demonstrate good weldability. They are easily and readily weldable through a variety of welding techniques such as shielded metal, gas metal and gas tungsten arc welding.

Nitriding is carried out to create a hard surface covering. In addition, nitriding increases the steel’s resistance to corrosion and abrasion. H13 tool steel can be nitrided at a temperature of 525°C / 977°F in ammonia gas.

H13 tool steel is a hot-working, chromium-molybdenum steel that’s durable and versatile such that it can be employed for various applications. It’s imperative to understand the attributes and technicalities of the steel so that you can select the right material for your project.

VEM Tooling has a vast experience of over 20 years in mold building and manufacturing high-quality plastic parts. Our team of experts can guide you to select the correct steel for your manufacturing solution.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.