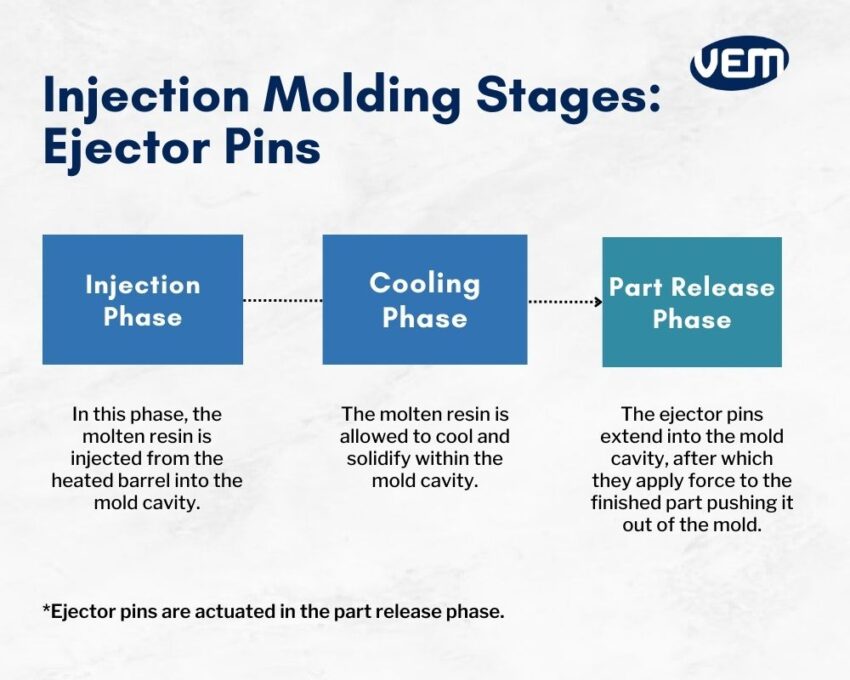

Injection molding is an efficient manufacturing process that involves injecting molten resin into a mold cavity to assume the mold shape and then ejecting the part upon cooling. Part ejection is the final but crucial stage of the injection molding process. At this stage, the part needs to be protected from various types of deformations and defects and thus, effective ejection systems are of prime importance in injection molding processes.

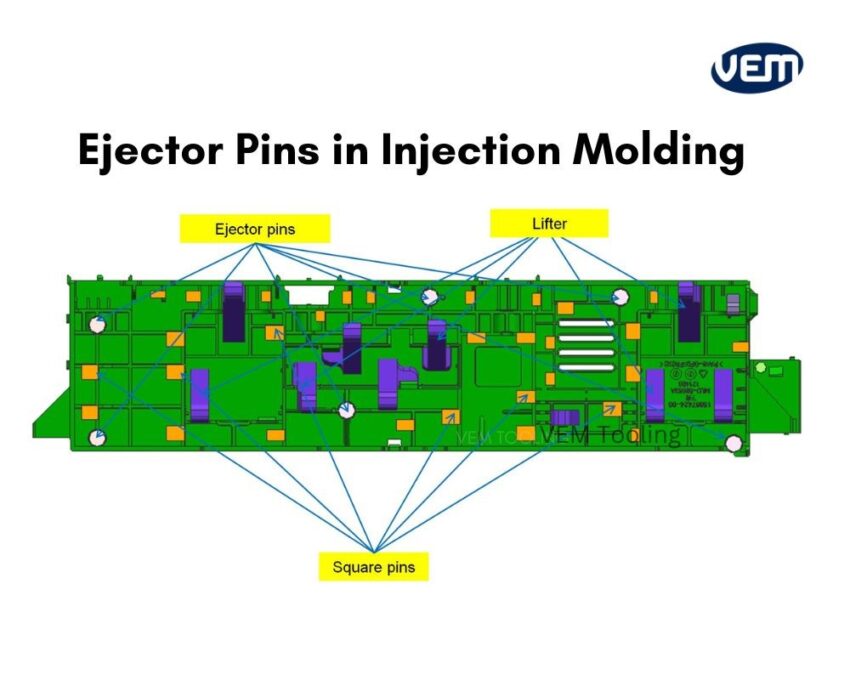

Ejector pins are an integral component of the ejection system in injection mold and its primary goal is to efficiently remove the finished parts from the molds.

Ejector pins in injection molding help manufacturers automate operations, increase efficiency, and improve production speed. It also helps to improve consistency in the product design. In this article, we discuss the various types of ejector pins, their challenges, solutions, and design considerations in-depth.

Ejector pins in injection molding are a type of ejector system and the mechanism is designed to remove molded parts from a mold cavity upon cooling.

This system increases efficiency as after the injection, an ejector pin pushes the molded part out of the mold cavity. Upon cooling, the mold cavity opens and separates, after which the ejector pin pushes the cooled part out of the mold.

To understand how an ejector pin in injection molding works, let’s first understand the various phases of injection molding:

There are two types of ejector systems in injection molding – manual and automated ejector systems:

There are several types of ejector pins and it’s imperative to choose a system that supports the molded part’s functionality and aesthetic properties. A wrong type of ejector pin may need to be replaced or have a shorter life span leading to extra expenses.

Let’s understand the various types of ejector pins in injection molding:

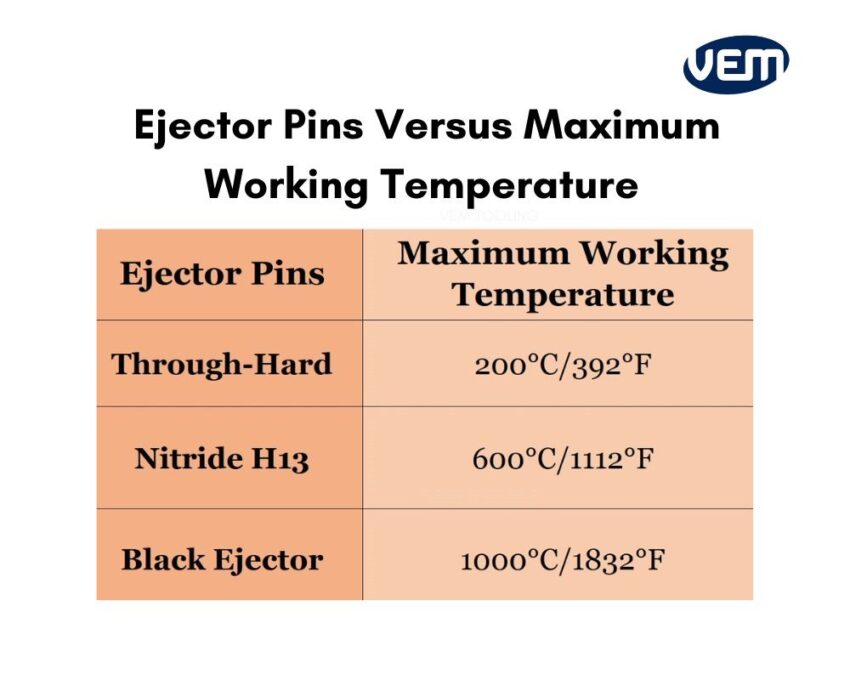

These types of ejector pins are heat-treated for consistent hardness throughout the pin structure and they can withstand working temperatures of up to 200°C/392°F. The hardness ensures they are wear-resistant and durable.

Through-hard ejector pins require heat treatment so that they can enable the pin diameter to withstand such high temperatures. They are mostly suitable for plastic injection molds, and they have the same hardness throughout the ejector pin’s diameter.

Nitride H13 pins are also referred to as case-hardened ejector pins and they can withstand a temperature of up to 600°C/1112°F. These pins are nitrated to have a surface hardness level of HRC 65 to 70 which enables them to withstand such high temperatures. This also increases the wear resistance of a pin’s surface.

Nitride H13 pins are created from H13 tool steel which is known for its excellent heat resistance. The nitriding process also enhances the surface properties of the pin thus, making it suitable for molding applications with corrosive resins.

Nitride H13 Ejector pins are mostly suitable for die-casting ejection systems in mold. These types of ejector pins can be drilled or tapped. You should note that these pins are relatively soft and can chip easily.

These types of pins are coated with a black surface treatment which is self-lubricating and helps to withstand higher temperatures of above 600°C/1112°F and up to 1000°C/1832°F. Black ejector pins are typically more expensive and incorporated for higher-temperature applications.

They are perfect for automotive applications and are mostly suitable for a metal ejection system in the mold of automobiles.

In addition to the above, some types of ejector pins are designed and applied as per the mold design. Let’s understand these types of ejector pins further:

Straight ejector pins feature a simple cylindrical shape and are commonly applied for parts with simpler geometries. They are typically applied for a straightforward ejection of parts from the mold cavity.

These types of ejector pins have a larger diameter at the shoulder i.e. the top and a smaller diameter at the tip. Shoulder ejector pins prevent the pin from sinking into the finished product during ejection thereby preventing aesthetic defects from arising.

Blade pins have a flat and wide surface at the tip. This feature makes them apt to be applied for ejection from deep and narrow cavities. It can also be applied to parts with uneven geometry.

These types of ejector pins have two distinct diameters. This feature enables a gradual ejection process and is particularly useful when gentler ejection is required.

Floating ejector pins are designed to accommodate slight variations in the dimensions of the part. They are designed such that there is a degree of movement so that these pins can adapt to the part’s shape during ejection.

In addition to the ejector pins, some systems can be incorporated to support these pins. Let’s understand the various types of ejection systems for ejector pins in injection molding.

Ejector sleeves are hollow ejector pins that consist of a hard-surface sleeve pin and a core pin that fits in the hole. The hole protects and guides the pin. In addition, it also protects the pin from wear and corrosion. Thus, ejector sleeves are often applied when long-term durability is crucial.

Ejector plates function alongside the ejector pins. An ejector plate holds the pinhead and prevents it from coming out during the injection molding process.

Ejector blocks are incorporated for parts that need a high surface finish. They have lubricating hollow grooves and are applied specifically to reduce ejector pin marks. They are typically applied to the surface of thin products and are also applicable on the surface of products with high warpage.

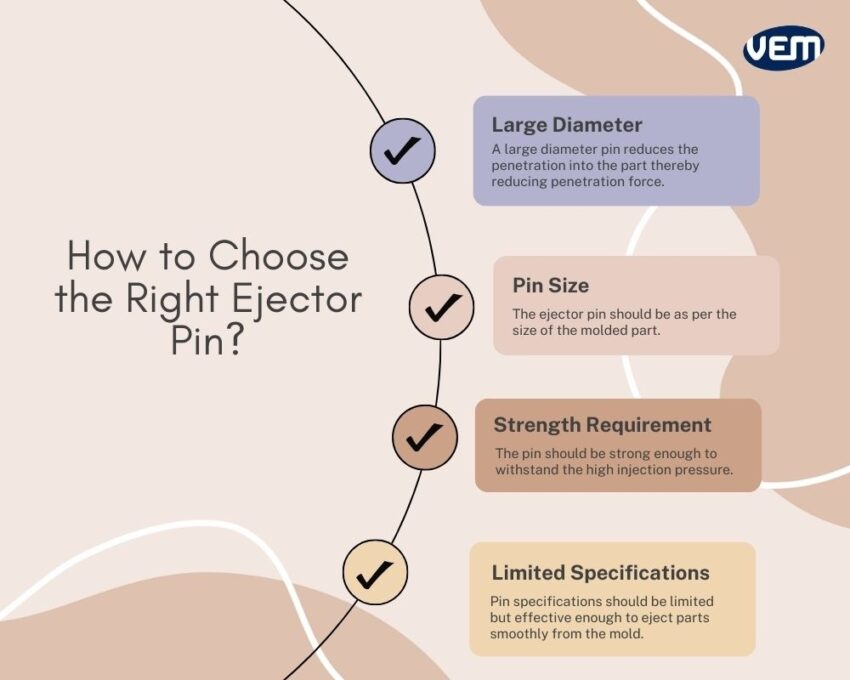

Selecting the correct ejector pin is crucial to facilitating an efficient part ejection while ensuring that the quality of the parts is maintained. Let’s understand how can you choose the right ejector pin in injection molding:

If the ejection position is sufficient, then an ejection pin with a larger diameter should be selected as it can provide increased ejection strength.

A large ejector pin that has a large diameter reduces the penetration of the pin into the molded part thereby reducing any type of penetration force.

Though it’s recommended that ejector pins should have a large diameter, you should note that the pin size should correspond accordingly. You should adjust the ejector pin as per the size of the molded part.

You should note that the ejector pins must be able to efficiently push parts out of the mold without causing defects or deformation thus, the ejector pin should be strong enough to withstand the high injection pressure.

If the specifications of the ejector pins are simplified, then the mold design and its maintenance can be simplified as well thus, you should ensure that the specifications are limited but effective enough to eject all parts smoothly from the mold.

A mold is made of two parts – Let’s suppose that the sides are A and B sides. When the resin cools in the mold, both sides separate to remove the finished plastic part.

Injection molds are designed such that when they open, the A-side mold half lifts with the formed part, and the ejector pins are located on the B-side of the mold half. The ejector pins on the B side of a mold push the part out of the mold.

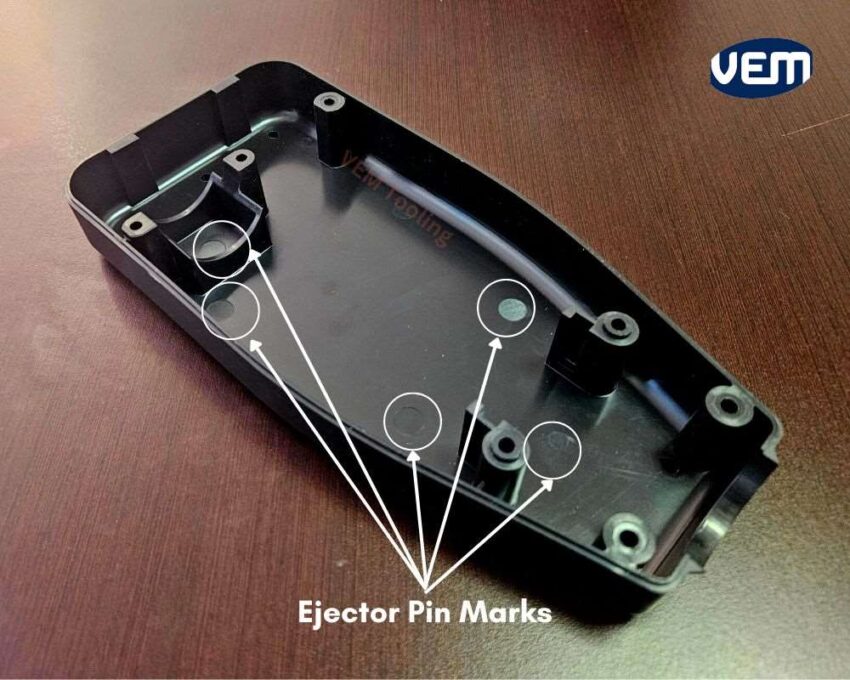

During the part ejection process, the ejector pin commonly forms imprints on the part. These imprints are also referred to as ejector pin marks.

In certain situations, ejector pin marks amplify and create functionally defective or aesthetically unpleasing defects. Let’s understand some of the challenges and solutions:

When the part does not cool enough to solidify and the ejection process starts, the pin can penetrate the part leading to functional and aesthetic defects. You must, thus ensure enough cooling time to let the part solidify completely in the mold.

Ejector pin marks are more prominent on very thin parts. A general thumb rule is to ensure that the injection molded part has a wall thickness of at least 2.5mm / 0.09 inches. In addition, if an excellent surface finish is required, you should consider using an ejector blade instead of ejector pins.

Dwell time is the measure of the time that the molten resin resides in the mold and dwell temperature is the temperature of the resin that is maintained in the mold.

The dwell time is typically higher than the glass transition temperature and it has a direct impact upon the properties of the resin. If the glass transition temperature increases due to dwell time and/or temperature, it could lead to premature ejection. In such a case, the part may not have completely solidified leading to the occurrence of ejector pin marks on the part.

Ejector pins need to be correctly placed and arranged which is largely dependent upon the complexity and the part design. We have listed below some guidelines for ejector pin placement and arrangement:

The occurrence of ejector pin marks can be mitigated by the implementation of the following approaches:

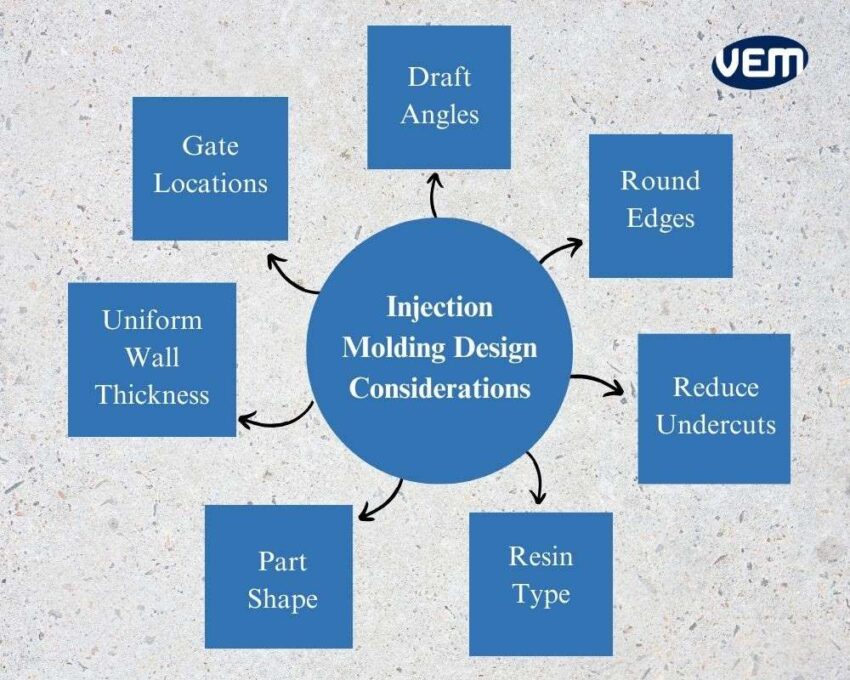

When the wall thickness is uniform, the molten resin flows freely and fills the cavity as per the defined shape. If the mold walls aren’t uniform, the thinner sections will cool faster than the thicker sections leading to stress concentration, and shrinking which eventually leads to the cracking of parts during ejection.

The draft angle is a slant in shape and is applied to both sides of an injection mold. Its slight distortion in the mold enables efficient removal of the finished part from the mold.

Draft angles help to provide resistance against friction during part ejection. If the draft angles are not included, then the ejector pin marks on the part can be enlarged.

You should note that sharp corners limit the plastic flow and are also difficult to remove whereas round edges on the inside and outside of the part reduce stress concentration and prevent the part from cracking.

Undercuts are protruding features that are necessary in the mold design. They prevent direct ejection of the part from the mold.

Though undercuts are unavoidable, the design team should try to reduce the number of undercuts in an ejection system. They can also be remedied by creating interlocks or latches that enable easy removal of the part.

Gates are the points through which the molten resin enters the mold and upon cooling, the ejector pin can push off the resulting pin mark from the gate. Thus, the gates leave a pin mark, which is visible even after dent removal.

This can be remedied by using an edge gate, where the dents are less noticeable.

The type of resin affects the pin size and its placement. Some materials are stickier or thicker while others require more force to release from the mold. If some resins are flexible, then others are hard or brittle.

The material type is largely dependent upon the design and function of the part.

You should also note that ejector pins aren’t used for parts made from liquid silicone rubber. LSR parts are manually removed from the molds.

Ejector pins require a flat area to push against. You should note that slants and curves can cause problems in the placement of ejector pins; thus, the surface must be perpendicular to the direction of pin movement.

Ejector pins are designed to efficiently remove the molded part from the cavity. There are several types of ejector pins and choosing the right one can be daunting.

If you’re interested in utilizing ejector pins for your mold, we can help you design the mold correctly to include the ejection solution for your part and budget! At VEM Tooling, we have more than 20 years of experience with plastic injection molding services.