Die spotting in the tooling industry

Die spotting uses a spotting press which applies pressure on the mold to check the contact surfaces between the moving side and the fixed side. Toolmakers use red or blue colorants to point out which surfaces are touching and which aren’t. It is needed to verify the tool before going into a trial press.

Why do tool makers need die spotting

Lowering mold cost with a die spotting press

Toolmakers invest heavily in high-precision machining to hold the tightest tolerances on steel.

Once all components are manufactured, the mold is being assembled and undergoes a molded fitting. This process is heavily labor-intensive and requires expertise. It does contribute a considerable to the mold cost.

Being able to utilize a spotting press during the mold fitting, increases the efficiency and quality of the assembly procedure. It almost directly translates into time savings and thus reduced mold costs.

Time-savings

The alternative way of testing a mold is using an overhead crane, lifting the moving part up and down. This way of testing might seem easy and quick, but it is by far not as accurate. There is simply no way to apply pressure on the mold by just using an overhead crane.

During the fitting process, it is likely that areas of the mold need to be re-fitted or even reworked. Grinding components to enable correct mold fitting is not unusual. This means that after every spotting approach, the worker has to open up the mold and might work on both sides.

Modern spotting presses can open a mold and present it on a plate within a minute. The plate can then be used as a worktable to do adjustments on the mold.

Improving the success rate of mold sampling

Molding fitting is the last step before going into mold sampling. To avoid any trouble when going into sampling, it is required to perform mold spotting. As mentioned earlier, during die spotting, the mold and all its parting surfaces as well as moving components are verified.

Even a small issue with one moving component, can result in a failed mold trial. The problem is that the whole setup before starting to sample, takes hours. Depending on the mold size, a failed trial can cost you as much as half a day, plus the opportunity costs of the trial press.

Safety & Ease of use

Pulling up a heavy block of steel by a crane just to drop it doesn’t sound safe and it isn’t. Besides the damage it does to the floor, there is simply nothing positive about using a crane to fit molds f. A spotting press’ main design criteria are the safety of its user. It minimizes any dangers of mold handling that are normally thought of when using cranes, forklifts, or other lifting equipment.

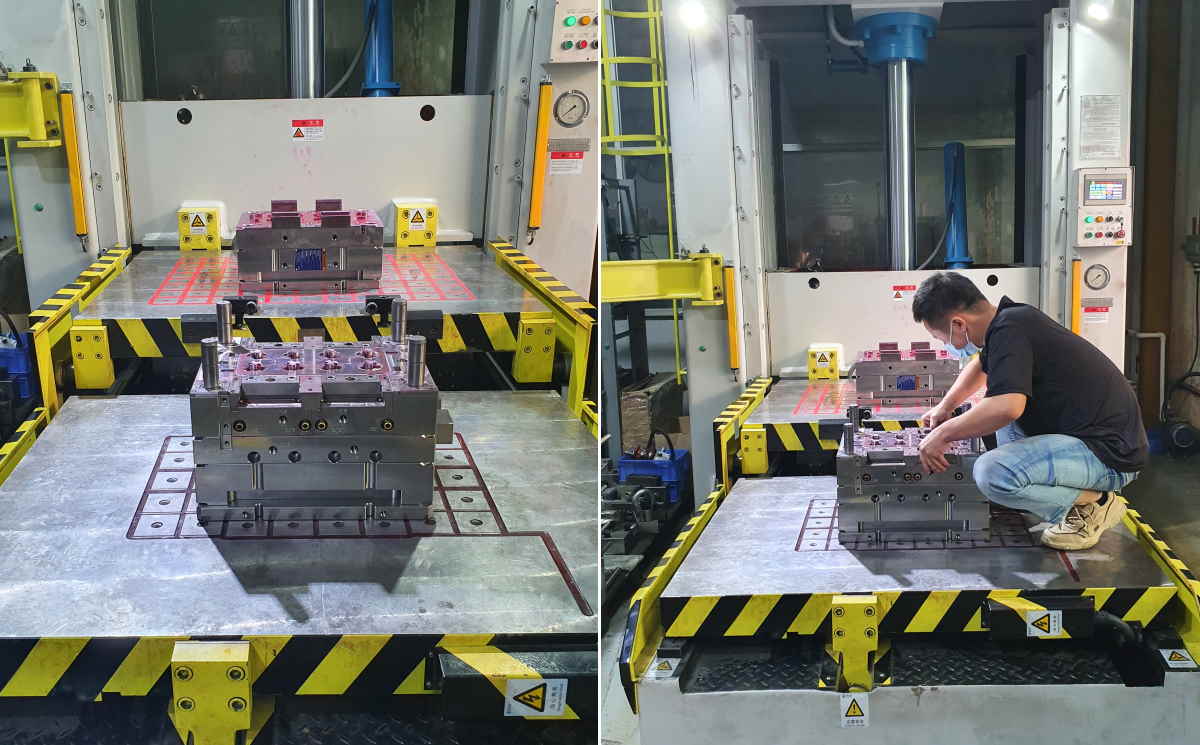

The ease of use of a spotting press is superior. The whole process is highly automated and requires minimal physical interaction of the worker. Additionally, the ergonomics of having a mold half being presented on a plate, after spotting, is incredible.

Die spotting process

The die spotting process is part of mold fitting. It is crucial to ensure and verify a mold before it goes into the trial press.

Modern machines have made this process easy, safe, and efficient.

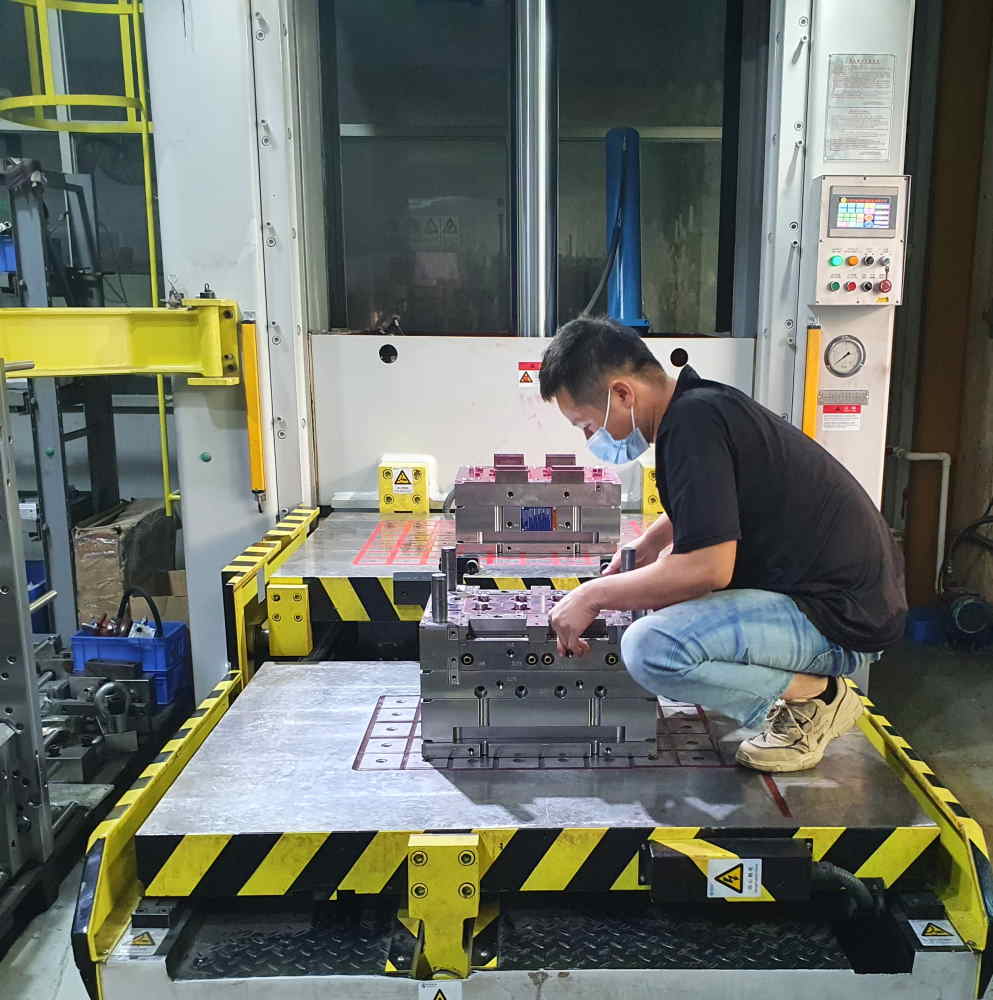

Loading mold on spotting press

Place the mold in the middle of the colors rectangle on the spotting press. In advance you should check a few criteria, to avoid running into problems later.

Ensure that the mold weight is within the capacity of your spotting press. Additionally, the opening gap of your spotting press needs to be sufficient to fully open the mold. Otherwise you will run into problems when swiveling the plate for mold adjustments.

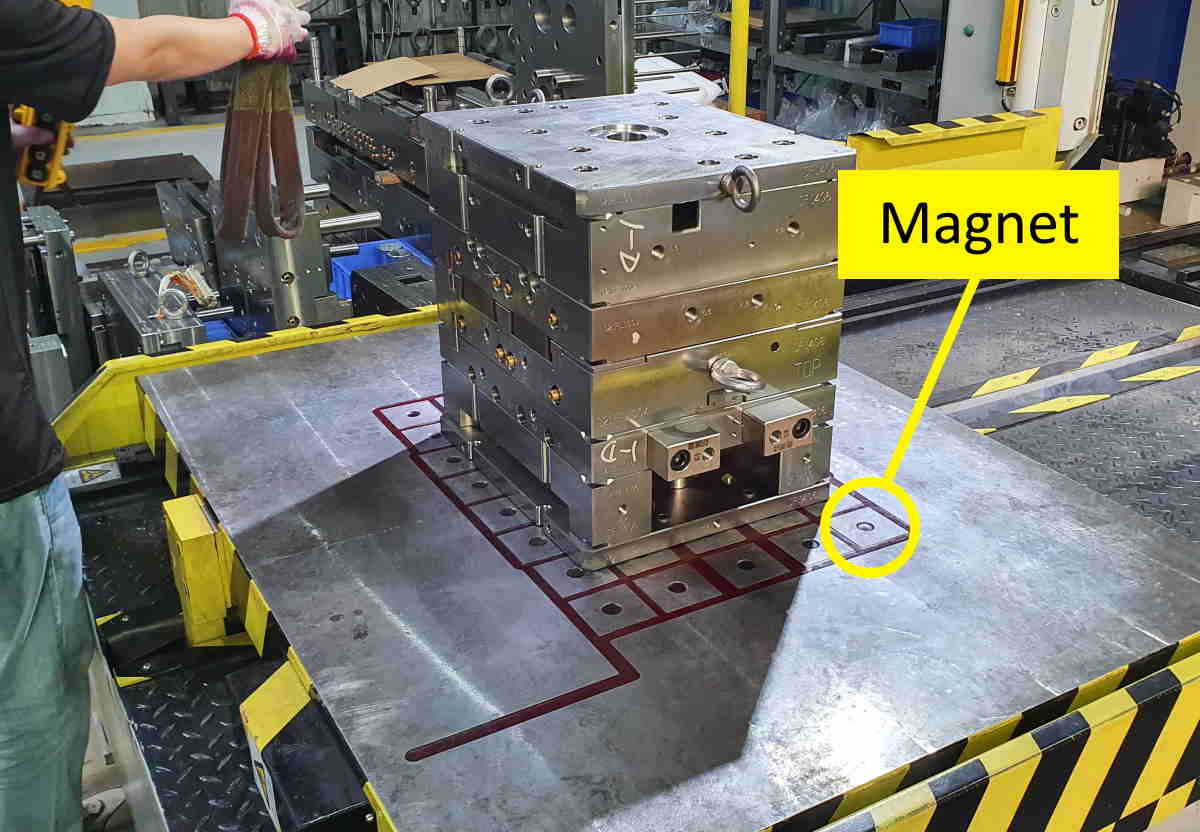

Utilizing magnets, alternatively clamping

This step is where a good, modern spotting press distinguishes itself from the older ones. Old machines often require the worker to clamp the mold manually, which requires a lot of putting screws and locks in uncomfortable positions.

Fortunately, many modern spotting presses have strong magnets that only require the worker to push a button.

Applying pressure on the mold

Now comes the core function of a spotting press. It asserts pressure on the mold to simulate the situation while injection molding. It does not have to be the same amount of tonnage as your injection pressure but needs to be enough to test parting surfaces and the movement of components such as sliders and lifters.

Open and close the mold several times in sequence to verify that all moving parts have enough clearance.

Adjustments on the mold

After finishing the spotting process, the machine opens the mold and moves both plates. Modern machines can swivel their upper plate by 180° degrees so that it is easily accessible for workers.

This feature is among the most important features to ensure efficient operations. While mold fitting, it is likely that issues occur. In those cases, it is often needed to re-fit the mold or to re-work some of the components. Many mold makers have grinding equipment nearby the spotting press, to be able to fix issues related to that.

Buying a die spotting press

Generally, it is advisable to buy the size needed in most cases. The rare occasion of a larger mold does not necessarily justify the extra cost of investing in a larger machine. Keep in mind, exception mold sizes can still be fitted in the old way, it just becomes more tedious and time-consuming. However, if the amount of exceptions is relatively low, buying a larger spotting press might just be overkill.

Most reputable die spotting press manufacturers have several options to suit all kinds of needs.

The main criteria to make a decision should be:

- Max. clamping force

- Max. load capacity on upper &lower plate

- Plate dimensions

- Opening height

Additionally, there are some features that increase the efficiency of utilizing a spotting press. Using magnets to fixate the mold base on the plate is not only safe but also saves plenty of time. It does not require the worker to get in unergonomic positions and just needs the push of a button.

Another important feature is to choose a spotting press that comes equipped with a 180° rotating plate. Especially small adjustments can easily be done on the spotting press’ plate. There is no need to remove the mold from it. Workers can conveniently work the open mold. As soon as the adjustment is done, the mold can go into the die spotting process right away.