Design is the cornerstone of manufacturing! A correct design ensures successful part development.

Design for Manufacturing is an organized approach and an engineering concept that enables manufacturers to design parts and products by accounting for actual aspects of manufacturing and its constraints. It is estimated that approximately 70% of the manufacturing costs can be optimized if design decisions are made in the early design stages. Thus, Design for Manufacturability has great cost-reduction capabilities.

DFM enables manufacturers to identify constraints and make adjustments in early design stages which helps in efficient product development. It aims to drive efficiencies, promote smooth, cost-effective product manufacturing, and deliver high-quality products. This is achieved by simplifying, optimizing, and refining the product design. In this article, we discuss design for manufacturing, its consideration factors, and various advantages in detail.

DFM, abbreviated for Design for Manufacturing, is also called Design for Manufacturability. DFM optimizes the design of a part or product to improve its efficiency and increase its cost-effectiveness.

DFM guidelines enable manufacturers to design a part efficiently, typically during the product design stage. It enables a manufacturer to identify and prevent errors which ultimately helps to reduce manufacturing costs. Design for Manufacturing strengthens the ability of a manufacturer by improving upon speed and quality while reducing costs.

Design for Manufacturability is an organized approach that aims to streamline and simplify the manufacturing process, maintain or improve the quality, and reduce manufacturing and assembly costs.

A successful DFM implementation is an ongoing process. Let’s understand the various stages of the implementation processes:

At this stage, the main aim is to integrate Design for Manufacturing early on, in the product development cycle. This is a concept development stage. The key aspects of this stage are to conduct a preliminary DFM assessment, involve manufacturing engineers in initial design discussions and establish specific DFM guidelines.

The successful implementation of Design for Manufacturing requires a systematic approach from all stakeholders of a cross-functional team.

All the stakeholders of the cross-functional team must conduct Design for Manufacturability review meetings. You should also note to implement a platform for shared data of design and manufacturing.

In this stage, Design for Manufacturing analysis tools and techniques are implemented for identifying and addressing manufacturability issues.

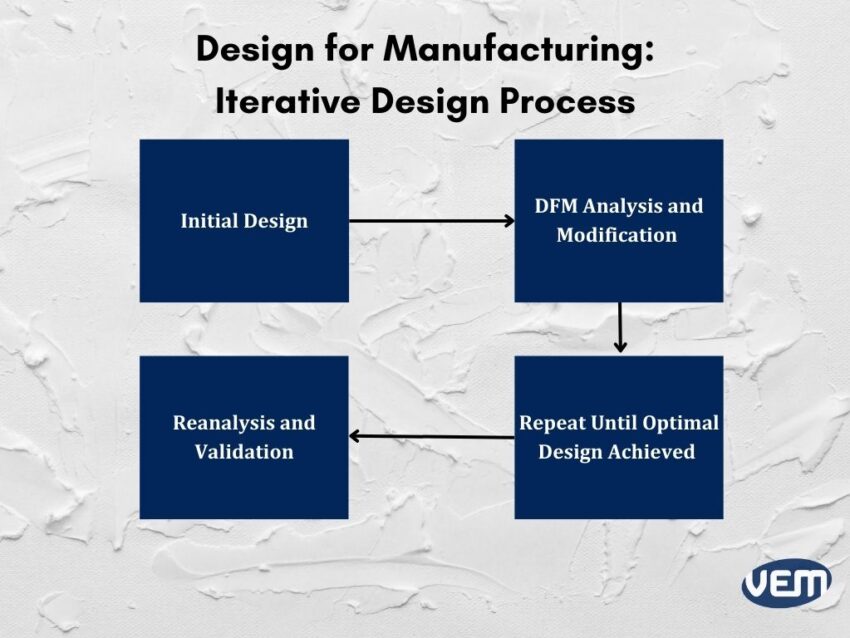

Design for Manufacturing is an iterative design process to ensure continuous improvement. The iterative process is demonstrated in the below infographic:

The last stage of Design for Manufacturability is to implement DFM through validation and testing. This stage ensures that the product performs as intended, and meets all the criteria and safety standards.

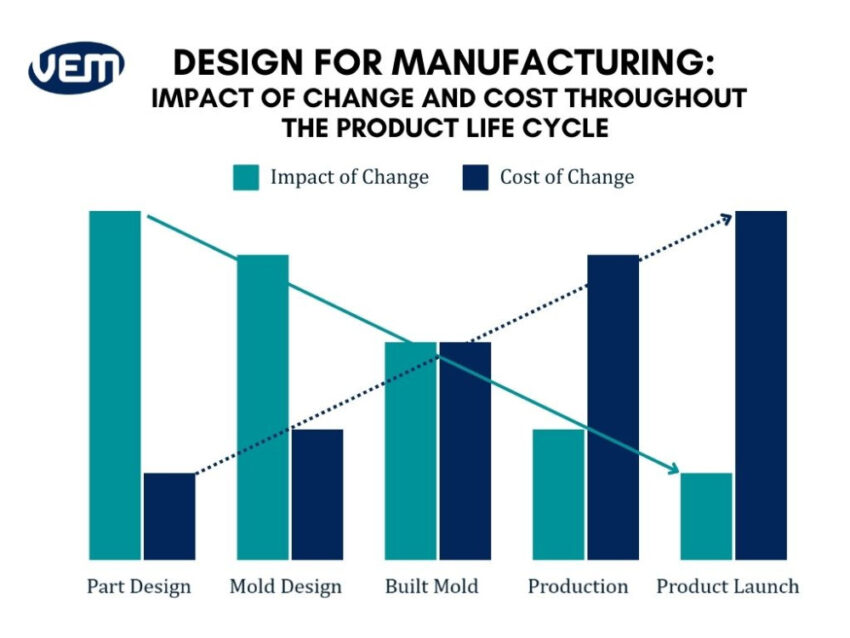

DFM must be conducted early on, in the design process. It should be performed before the tooling begins. You should note that as the design progresses through the product life cycle, changes become more difficult and expensive to implement. When the Design for Manufacturability is conducted early, it enables easy implementation of design changes. The following diagram illustrates the impact of change on the cost during the product life cycle:

The timeline for DFM varies extensively and is dependent upon various factors. On average, a DFM process may take around two weeks to complete however; this time may increase to three to four weeks or even more for more complex products. Let’s understand these factors further:

Part geometry has a major influence on the Design for Manufacturability timeline. If the part design is more complex, more time is required to analyze and create adjustments.

DFM timeline is affected by the tools and the software involved in the process. If the DFM tools and software are effective and advanced, it can speed up the process through automation.

Prototype testing may be crucial for your project and is certainly essential for ensuring product quality and manufacturability. Thus, you should note that if there is a requirement for prototype testing, it can increase the Design for Manufacturing timeline.

The next factor that can impact the DFM timeline is the experience and expertise of the team. If the team is experienced, it can identify and analyze issues faster.

It’s crucial to have prompt and effective communication between the various teams to ensure that there are no delays. If the communication is not coherent, the timeline can be impacted by delays.

You should note that the number of iterations that are required can significantly impact the Design for Manufacturability timeline.

Design for manufacturability is typically an iterative process. It involves various repetitive rounds of analysis and this aspect is dependent upon various factors.

The availability of the supplier can directly impact the timeline as it affects sourcing components or materials. If the design and manufacturing requirements are not adequately met due to supplier unavailability, it can lead to delays.

Geographic locations play a vital role in the Design for Manufacturability timeline. Factors such as logistics and manufacturing location, increase the time.

Design for Manufacturing must include all the stakeholders from various areas to ensure that it makes a cross-functional DFM team. You should also note to include all the stakeholders early on to ensure that the process is streamlined and cost-effective.

A cross-functional DFM team reviews the design through various aspects and provides holistic input to ensure that the design is optimized. Let’s understand the roles of the various stakeholders:

Design engineers create the initial product design and work with other teams to ensure that the design can be manufactured in a cost-effective manner and efficiently. They consider various factors such as materials, tolerances, environment, assembly, etc.

Manufacturing engineers provide details and inputs about how the part can be manufactured and how the manufacturing process can be optimized. Their input involves selecting the correct manufacturing processes, equipment, and tools and minimizing manufacturing costs.

Product managers recognize the product requirements and their goal is to guide the design and manufacturing teams. The product manager is responsible for aligning the product with the company’s goals and customer requirements.

Quality assurance, abbreviated for QA, and Quality control, abbreviated for QC control the quality standards of the part or the product. QA and QC teams define the quality standards and play an extremely crucial role in identifying and addressing various quality issues that can arise during the DFM process.

A supply chain team ensures that the chosen suppliers can meet the quality and cost requirements. These teams source from the necessary materials, components, and suppliers required for manufacturing.

Cost estimators help businesses understand the various cost implications of the design. They understand the design to calculate the expected manufacturing costs.

A testing and inspection team is involved in defining the various processes of testing and inspection. This team ensures that the quality of the manufactured part is as per the required standards.

A regulatory and compliance team guides the various requirements of the regulatory bodies. They ensure that the design and manufacturing processes meet the required standards.

A continuous improvement team focuses on ways to improve manufacturing processes. They also identify opportunities for enhancing the quality and efficiency of the processes.

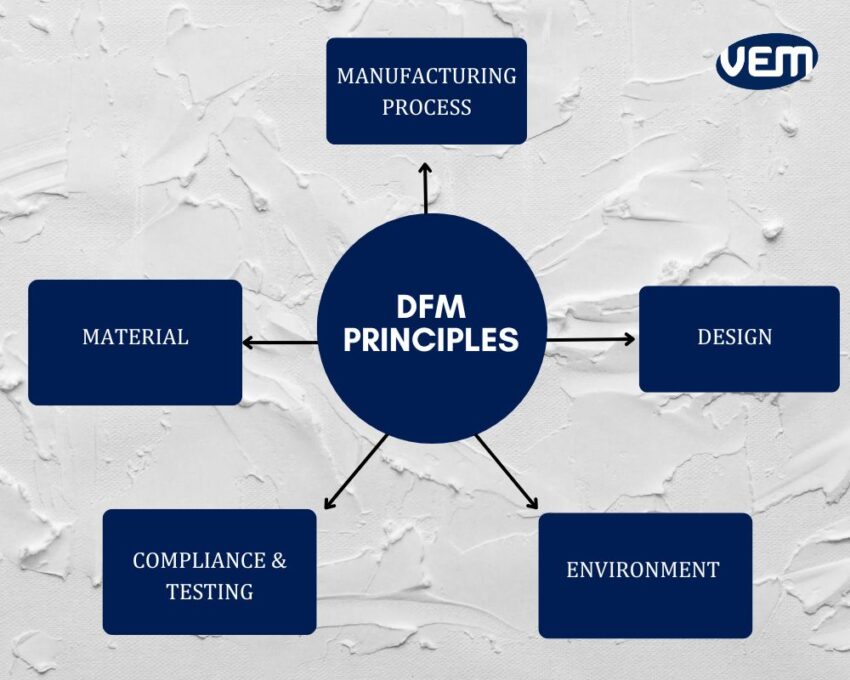

Design for Manufacturing optimizes product design for efficient manufacturing by focusing on key principles such as process, design, material, environment, and compliance. Let’s understand Design for Manufacturing principles further:

The type of manufacturing process that is implemented must be apt for the part. The process should be optimized to fit each component and Design for Manufacturability takes into consideration various factors such as parts quantity, material being used, surface complexity, and tolerances.

For instance: If it’s a low-volume production, then a manufacturing process such as thermoforming can be implemented instead of injection molding.

It is imperative to conform the design of the part to good manufacturing principles of the selected process. The part design must address various details such as thicknesses, texture, consistency, and greater specifications for tolerance. You should note that the more complex the design, the higher the risk.

The next Design for Manufacturing principle is selecting the correct material for your part. Materials have a significant impact on the cost and the quality of the part thus, it is crucial to choose the right materials for the part in the early stages.

There are various properties to be considered such as mechanical, optical, color, electrical, flammability, and thermal properties.

The part must be designed to withstand all types of its intended environment. It is crucial to consider every operating condition to ensure that the various parts of a product can perform their functions correctly under its normal operating environments.

The next and final Design for Manufacturing principle is compliance and testing. It is critical that the parts and products are tested thoroughly for safety and quality standards of the regulatory agencies and industry standards. They should also be tested as per, internal, company-specific standards.

Manufacturing Processes

Product Variants

Design Costs

Failure Analysis Tool Feedback

Regulatory Requirements

Material or Component Availability

DFM shortens product development cycles by eliminating design flaws. It also avoids expensive re-designs which can lead to increased costs and slower product development.

Design for Manufacturability simplifies processes of various stages thus, enabling shorter product development cycles.

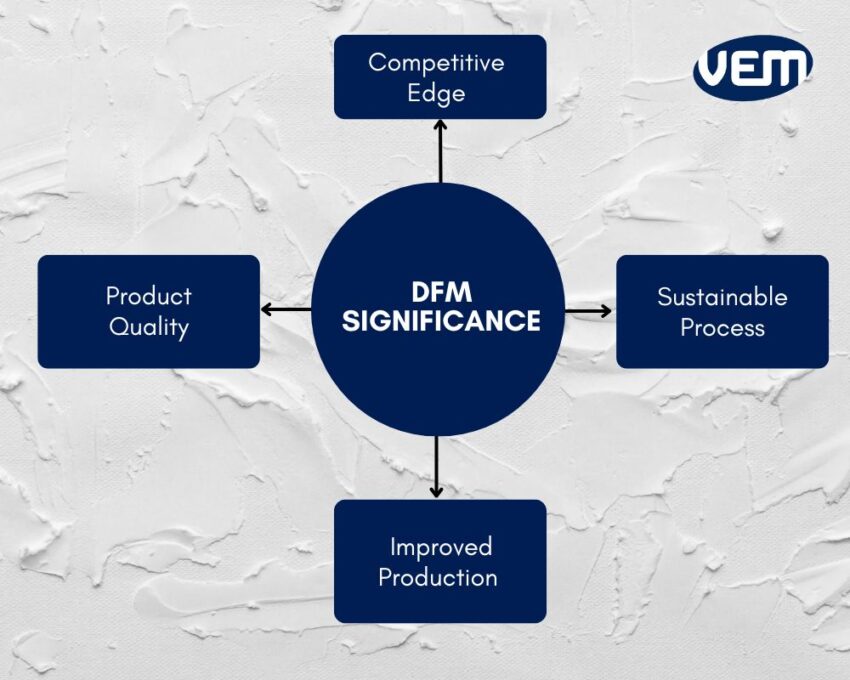

When parts are designed for manufacturability, the cycle time is faster and the labor costs are reduced. Thus, increased operational and production efficiency can be achieved.

Design for Manufacturability adds value to product designs through the exploration of different design options. Thus, design for manufacturability contributes to an improved design of the product.

One of the main aims of Design for Manufacturability is to identify and modify or eliminate design features that can lead to manufacturing defects. Design for manufacturability simplifies and modifies the design to attain a higher product quality.

DFM optimizes various aspects of manufacturing such as its processes, design features, and materials selection. This leads to enhanced product performance and can result in products that meet or exceed customer expectations.

Design for Manufacturing enables manufacturers to develop innovative solutions in the design process. Innovations through DFM cannot only solve the problem but also differentiate the part from its current marketplace.

DFM enables manufacturers to meet the various compliance and safety standards of the regulatory bodies early on, in the design stage. It thus helps to incorporate quality and compliance in the product life cycle.

DFM eliminates design iterations, incorporates efficiency in product development, and reduces the product cycle time. All this helps the manufacturers to get their products faster to the market. A faster time to market gives the company a competitive edge over its competitors.

DFM has a huge impact on reducing manufacturing costs. Design for Manufacturability enables manufacturers to optimize design by identifying and removing design features that increase costs. It also reduces production costs by reducing part numbers and saves material.

DFM reduces manufacturing defects which in turn reduces scrap and waste that would have been otherwise created during production. It thus, also contributes towards developing a more sustainable manufacturing process.

Design for Manufacturability addresses potential hazards, early in the design phase. This measure proactively reduces the risk of accidents and thus, helps to create a safer working environment.

DFM is an extremely beneficial process for product design and development.

VEM Tooling has over 20 years of experience in manufacturing high-quality parts. Our experienced engineers can guide you throughout the Design for Manufacturing process and other manufacturing solutions such as injection molding and tool building.