At VEM Tooling, we take pride in being a world-class toolmaker with 30 years of expertise in designing and manufacturing high-precision injection molds. With over 9,000 molds produced, our in-house capabilities in 3 different countries ensure a smooth progress with your project.

Unlike many manufacturers who outsource key processes, we make all our molds in-house. This means we maintain full control over quality, lead times, and cost efficiency. Our streamlined production process ensures that our customers receive molds that are not only built to the highest standards but also delivered on time and within budget.

To cater to each market with a minimized carbon footprint we have advanced tooling facilities around the world:

Total staff: 50

Project managers: 5

Mold designers: 2

Total staff: 180

Project managers: 11

Mold designers: 15

Total staff: 105

Project managers: 5

Mold designers: 15

VEM Tooling is working with industry leaders in the automotive, aerospace, medical, electronics and consumer sectors. Our commitment to precision, reliability, and innovation has made us a trusted manufacturer.

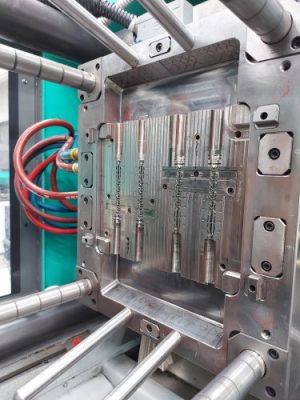

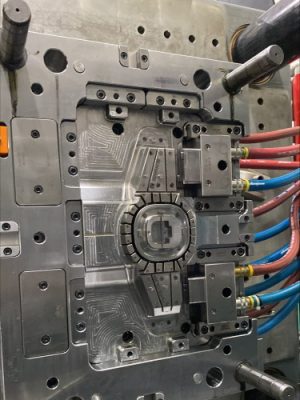

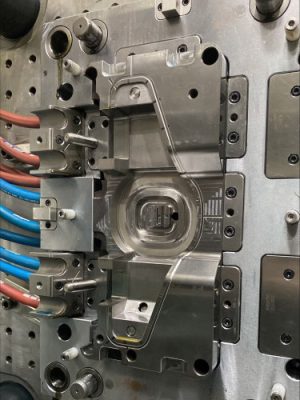

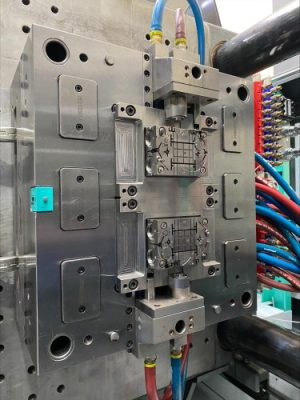

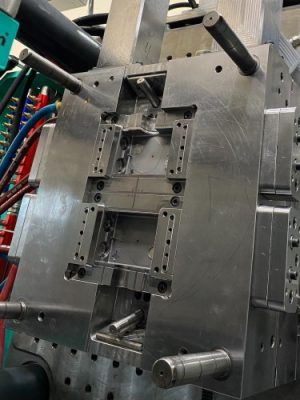

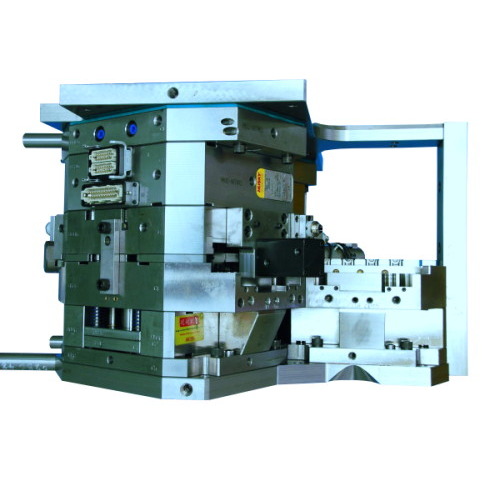

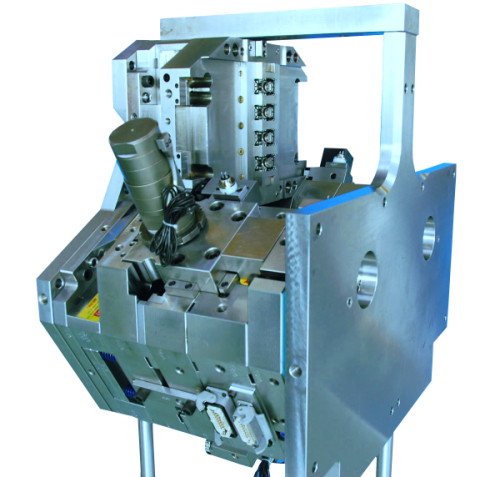

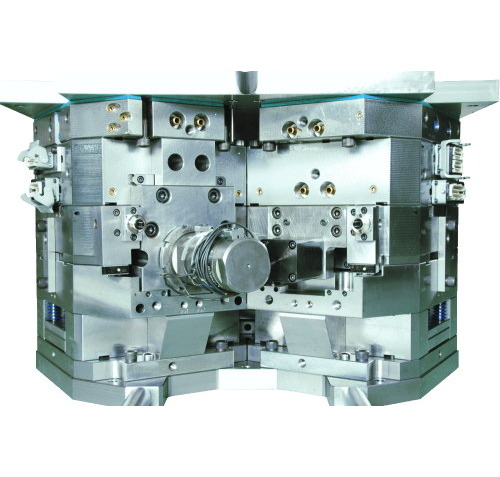

Over the decades we have made injection tools ranging from high precision, multi-cavitation, 2K-tools, overmolding tools and micro-molding tools. Your projects tooling needs are in good hands.

Our State-of-the-art machinery is from Japan, Switzerland, Germany and China. With those we can tackle even the tightest tolerances in this industry. You can find our machine lists here.

30 years of experience in mold manufacturing

Over 9,000 molds produced for global customers

State-of-the-art machinery from Japan, Switzerland, Germany, and China

Highly skilled toolmakers with decades of expertise

100% in-house production for superior quality control

Competitive pricing and fast lead times