VEM Tooling is a leading manufacturer of precision plastic components for the automotive sector. We deliver lightweight, durable, and high-performance solutions that align with the industry’s stringent quality and safety requirements. Our commitment to advanced manufacturing enables cost-effective, efficient, and reliable production for automotive brands worldwide.

VEM Tooling is certified with IATF16949 and ISO9001,

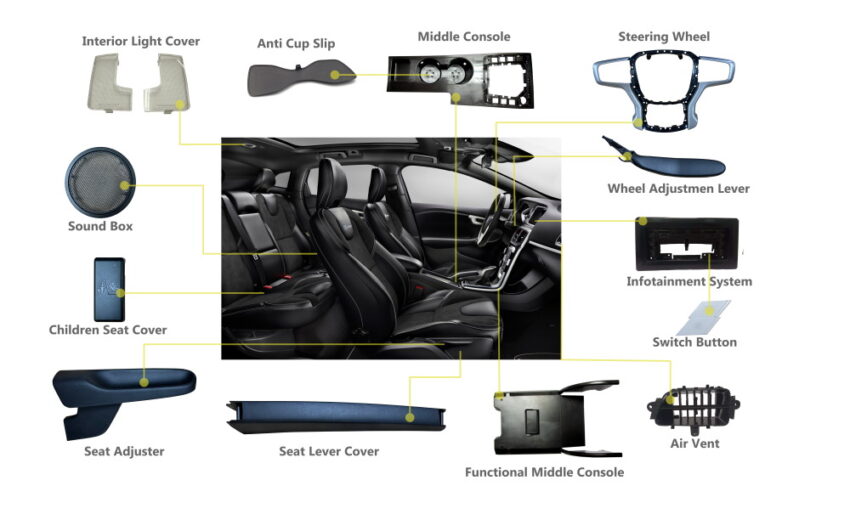

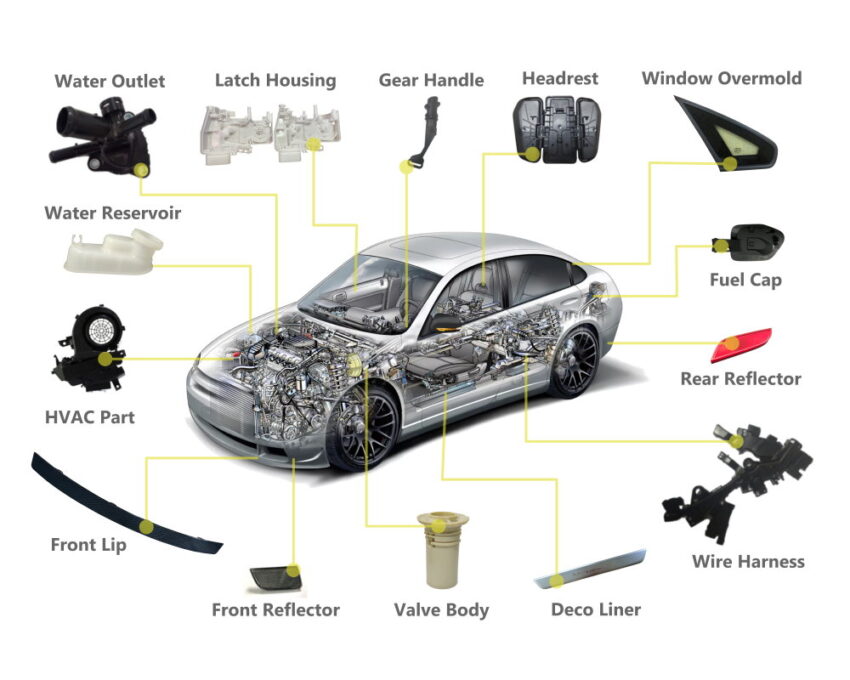

VEM Tooling specializes in precise and quality plastic components for automotive interiors, exteriors and functional areas. Our expertise with the strict automotive industry regulations makes us an ideal partner for Tier 1 and Tier 2 suppliers in the automotive industry.

Our sophisticated processed and state-of-the-art machinery ensures superior quality, cost efficiency, and fast turnaround times.

Car interior

Car exterior

Car functional

Over decades we have gathered extensive knowledge in processing and manufacturing automotive plastic parts with high-performance engineering plastics.

Mold manufacturing and maintenance is always done in-house at VEM Tooling. We have 3 Toolshops, Bulgaria, India and China, which supply our molding facilities with molds. Maintenance and engineering changes can be done at each location, we have fully equipped tool rooms in every facility.

VEM Tooling is serving the automotive industry for many years and has streamlined processes and PPAP. New projects are launched and validated quickly and reliable with us.

Let us know if you have questions about an upcoming automotive manufacturing project, we are here to help.