We explore and research various topics in regards to plastics manufacturing and tool making. If you like to learn more about this industry, check out our in-depth articles.

Up and coming for years, South East Asia with its stable manufacturing environment, is in the focus of many OEMs.

Dimensional inspection is the pillar of most quality inspections in manufacturing operations, guaranteeing the quality required.

Aluminum molds are most popular for prototyping and small production runs, what makes them so special?

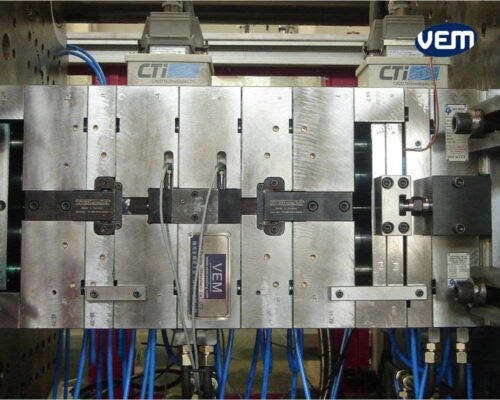

Most projects require custom plastic molds at some point of its life cycle. This usually happens when the quantity requirements exceed other options of manufacturing.

Custom plastic manufacturers have been working in the background for many OEMs, what's the secret behind it?

The global economy is seeing a new age of trade relations with tariffs becoming a major player. What does that mean for US companies?

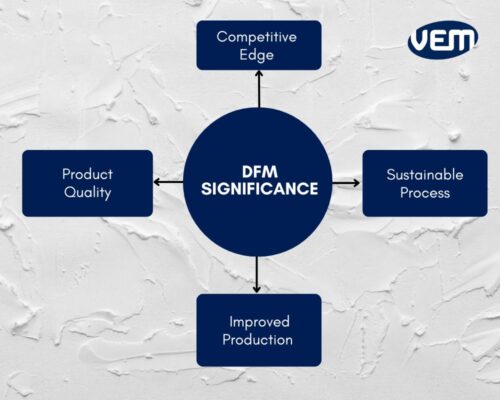

A Design for Manufacturing, abbreviated as DFM, is a substantial part of any manufacturing projects and follows simple but important guidelines.

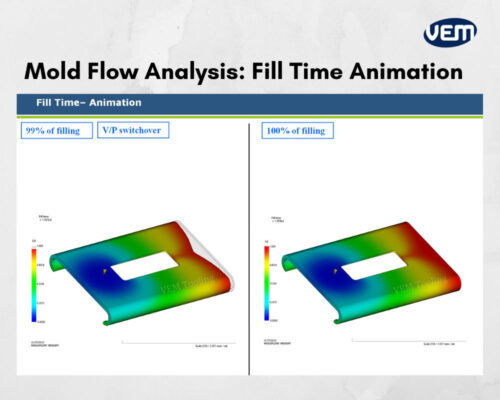

A Mold Flow Analysis is the filling simulation during the molding process and can reveal issues early on.

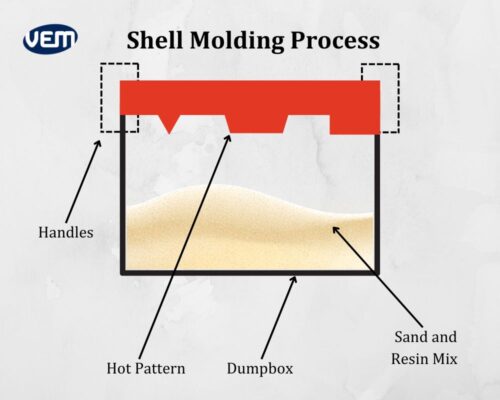

Shell Mold Casting is a metal casting technique that often uses resin cover sand for its shell.

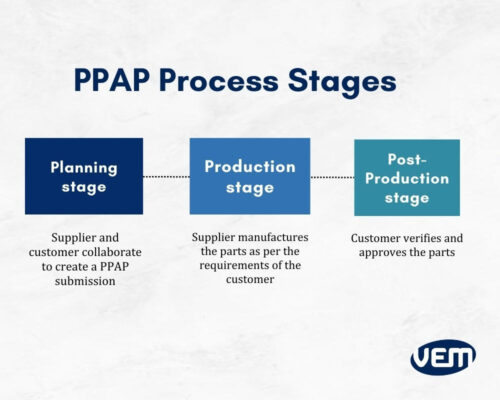

PPAP is commonly used in the aerospace and automotive supply chain for production processes.

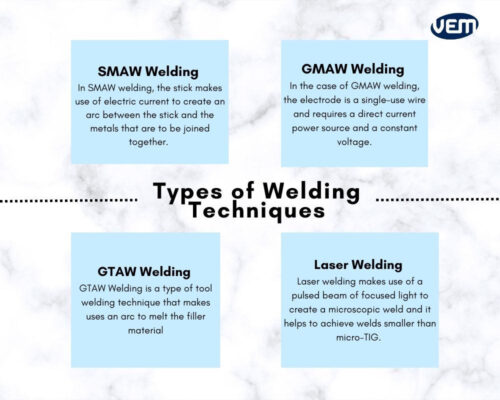

Tool Welding is an effective way to make quick changes on tooling without having to redo larger steel parts or inserts. It is also often used for repair.

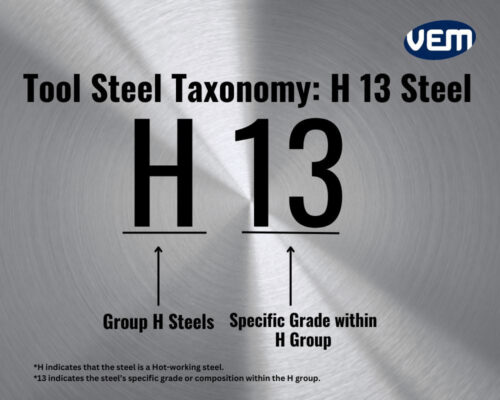

H13 is widely used for molds and dies due to its resistance to erosion, wear and thermal fatique.

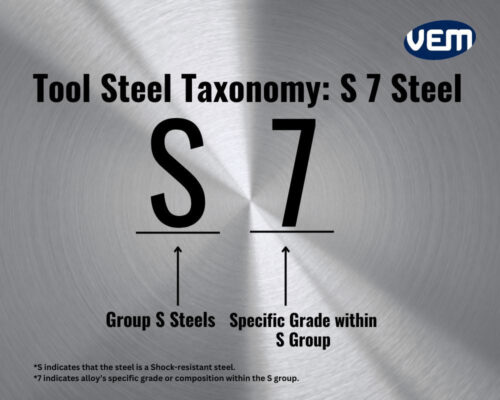

S7 is well known for the tool manufacturing industry due to its shock resistance.

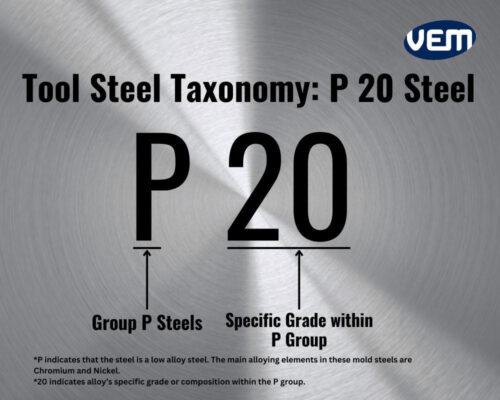

P20 steel if often used in mold bases due to its cost and mechanical properties.

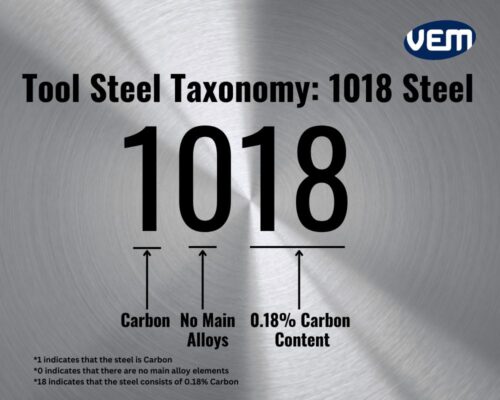

AISI SAE 1018 Steel is well known to be a tool steel with various characteristics.

Nowadays there are several material available for 3D printing applications, from plastics to metals and even wood.

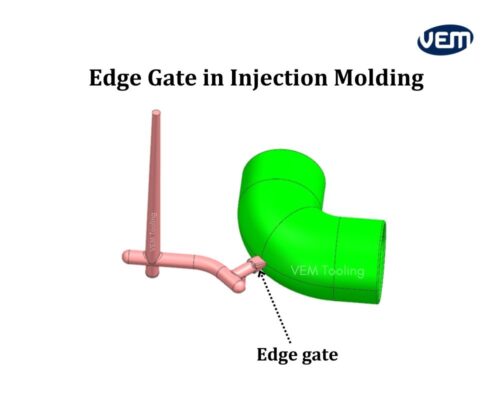

There are various gate types that can be used in injection molding projects, each has their own benefits and challenges.

One of the first important decisions to take before making a mold, is to select the correct Steel.

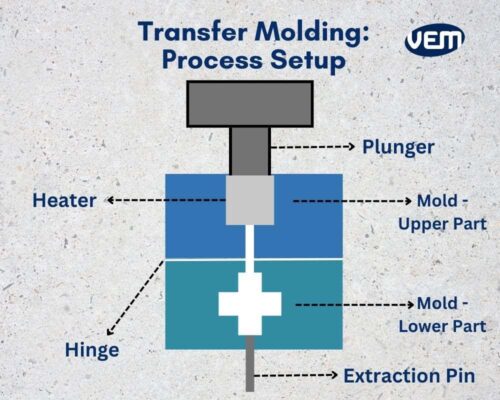

Transfer molding is hybrid in its nature, as it combines the fundamentals of both injection and compression molding.

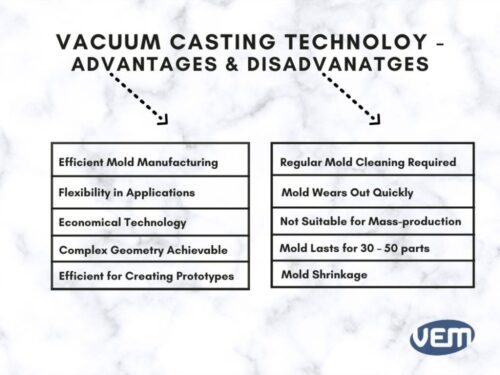

Vacuum casting is a good manufacturing technique to produce prototypes and is also often used in small volume production runs.

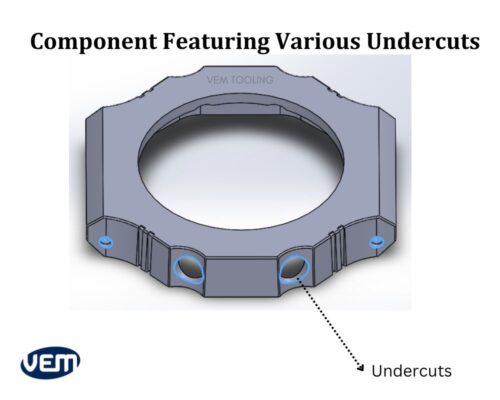

Undercuts are a common design feature of many plastic parts. While it creates additional work and complexity, there are several ways to deal with it.

Plastic parts can have all kinds of surface structures. To achieve those, the mold (steel) needs to be textured.

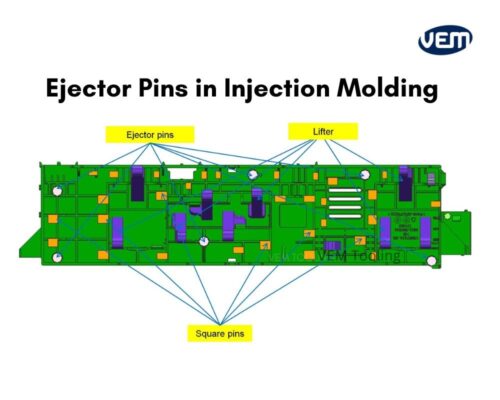

Ejection is a crucial part of the injection molding process, in many cases the use of ejector pins gets the job done.

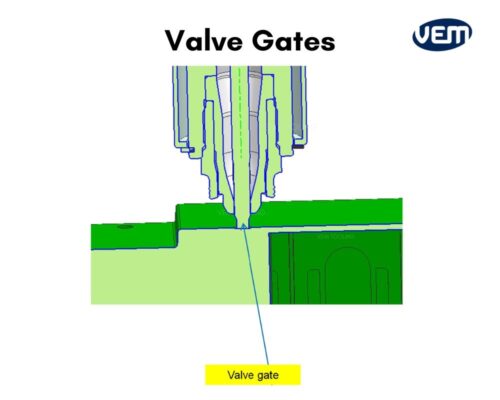

Better surface finishes and reduced gate marks in, injection molding, can be achieved with a valve gate system.

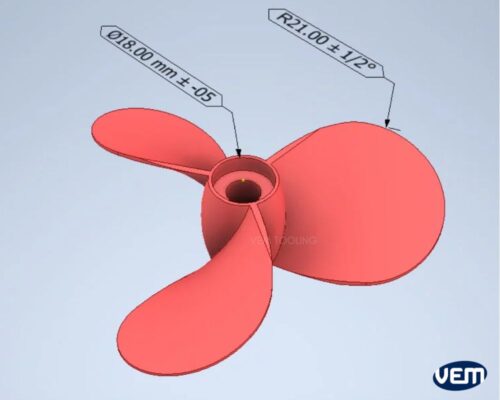

Molding tolerances play a crucial role in the use and acceptance of plastic parts.

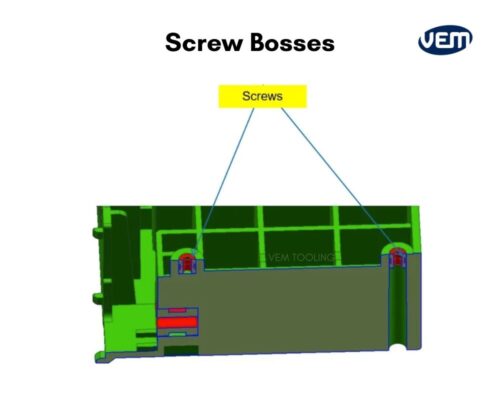

Screw bosses are a common design element in injection molding projects which accept inserts, screws, fastening or is used for assembling parts.

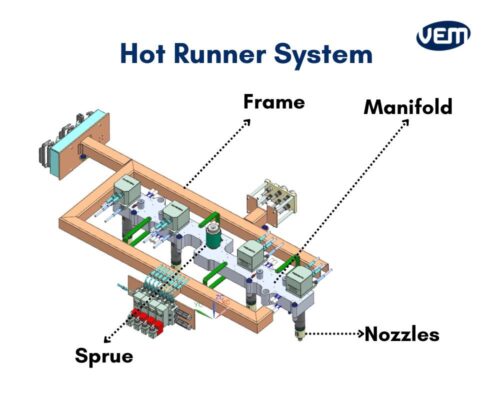

Hot runners or cold runners, many molders ask themselves this question. Let's take a look what hot runners are and when to use them.

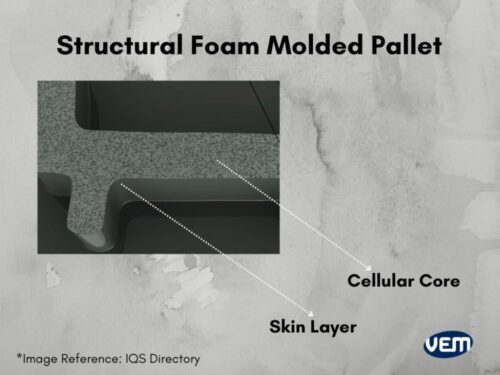

Foam molding is an integral part of plastic manufacturing, yet it often stands in the shadow. Learn more about it here.

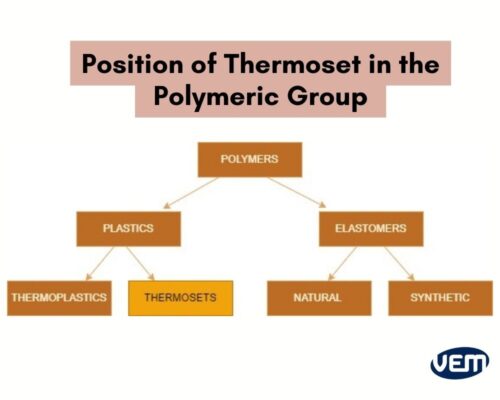

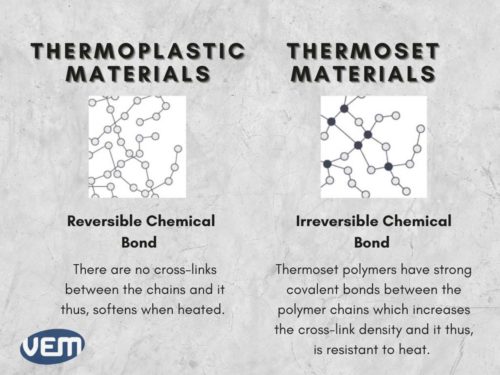

Thermoset plastics are commonly known in every-day products, but how does it differentiate from regular plastics?

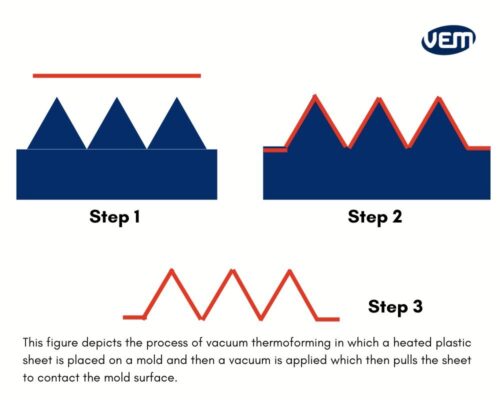

Find out more about thermoforming, how does it work and where is it commonly used?

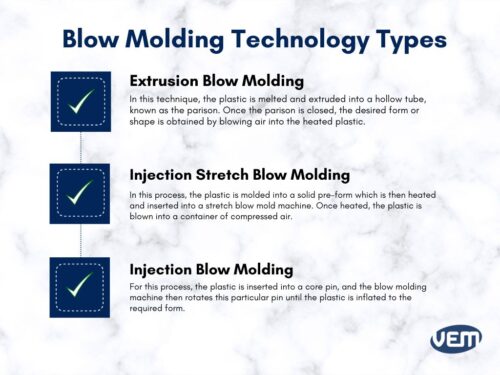

Products made from blow molding can be seen in every supermarket. Find out about the different blow molding techniques and what makes them special.

In-mold labeling is a common and very effective technique to get labels on your plastic products, during manufacturing.

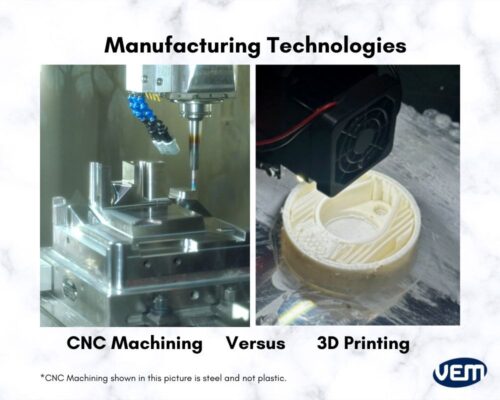

CNC manufacturing or 3D printing? There are scenarios where each has its edge.

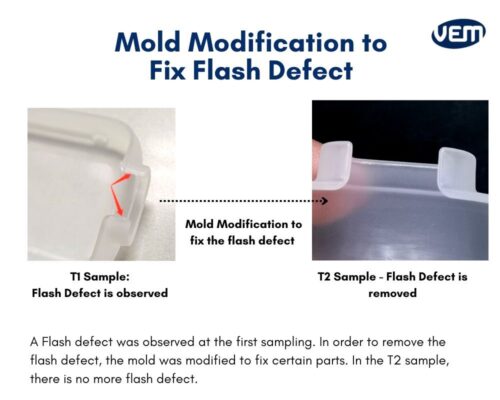

A flash defect is probably the most common injection molding defect on a part. What can be done to avoid and/or fix it?

Flow marks commonly occur as lines or circles and they indicate an uneven material flow.

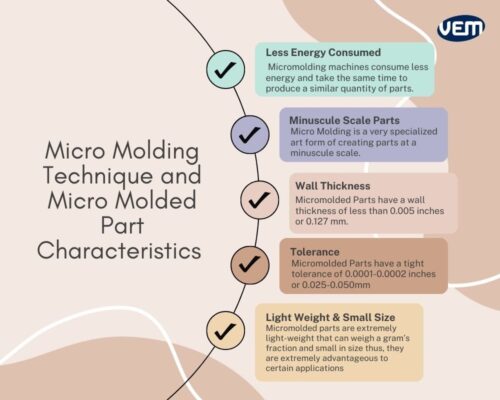

Micro-molding is a very specialized art form of creating parts at a minuscule scale via injection molding.

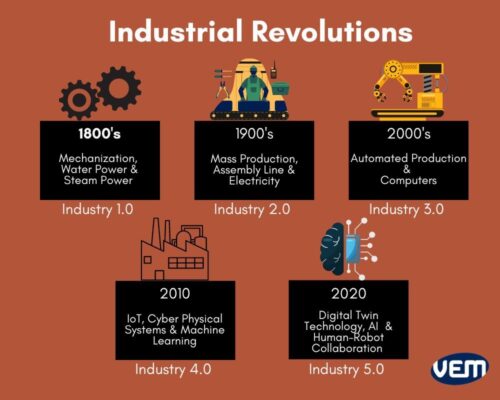

It’s crucial to have the right technology in place, we discuss the top manufacturing trends that will dominate in 2024-2025.

Raw material procurement is the backbone of many manufacturing businesses, what should you know about it?

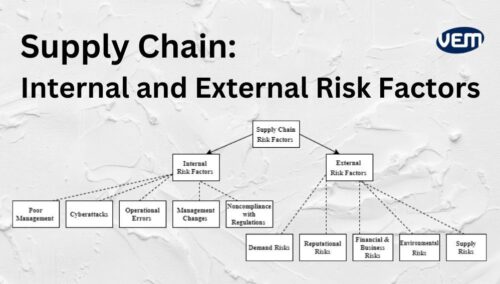

A supply chain risk management (SCRM) strategy helps businesses to operate more efficiently, and enhance customer service.

Disruption in the supply chain can turn out disastrous to any company that does not have a functioning contingency plan in place.

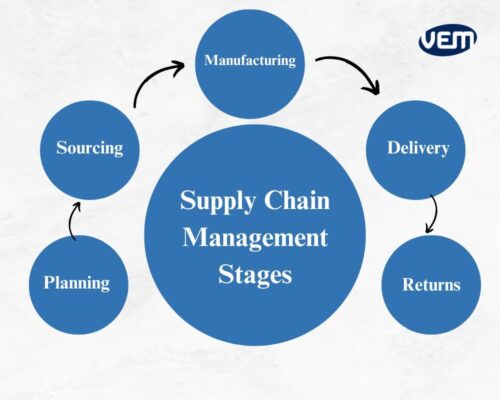

Successful supply chain management nowadays is crucial for any larger company. Have a look what defines & makes it work.

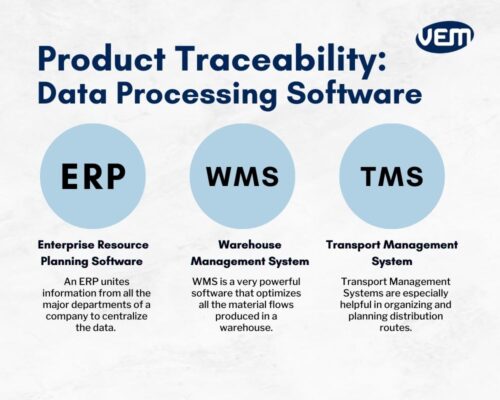

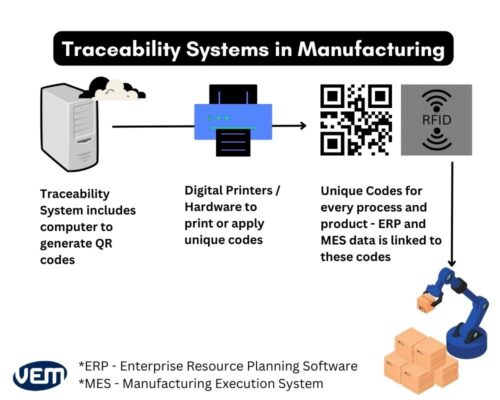

Product traceability does not only provide transparency, but also eliminates risks such as bad batches, counterfreit & more.

Traceability helps to determine every aspect of the manufacturing source, to improve quality, efficiency and transparency.

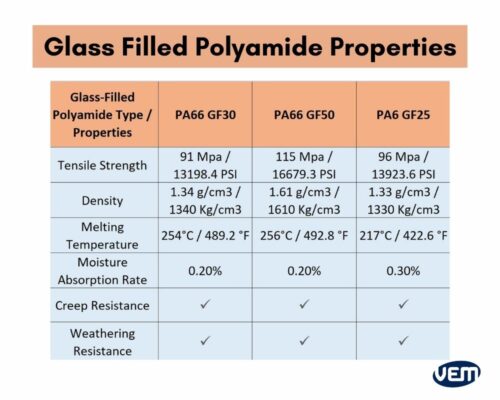

In this article, we discuss glass-filled nylon properties, their variations, and how it is used in manufacturing.

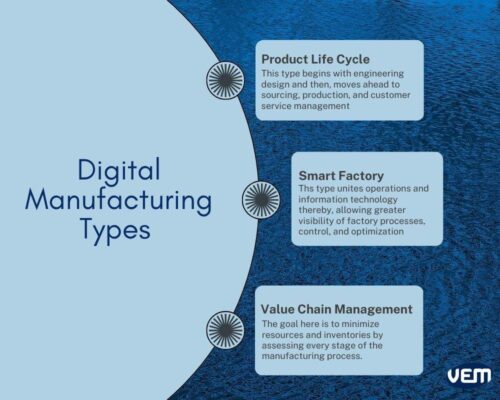

The goal of digital manufacturing is to increase efficiency and flexibility in the manufacturing process. This article is an in-depth and definitive guide to understanding digital manufacturing, its benefits, and use cases.

Soft tooling as well as hard tooling are common ways to produce plastic parts via injection molding. When to use which tooling type?

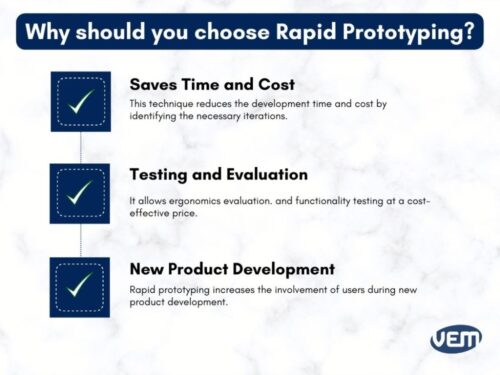

Rapid prototyping is used to create prototypes quickly during various design and development stages. It has become a standard in product development.

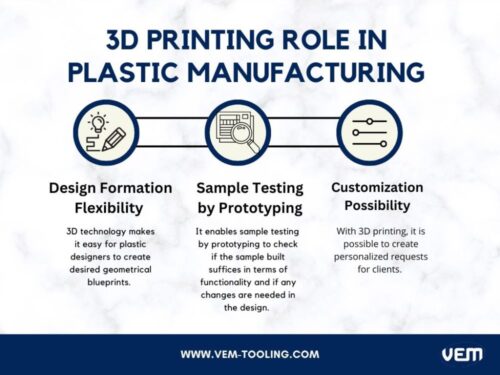

3D printing is becoming a regular technique in modern plastic manufacturing. The use cases start from prototyping, customized production to low volume production.

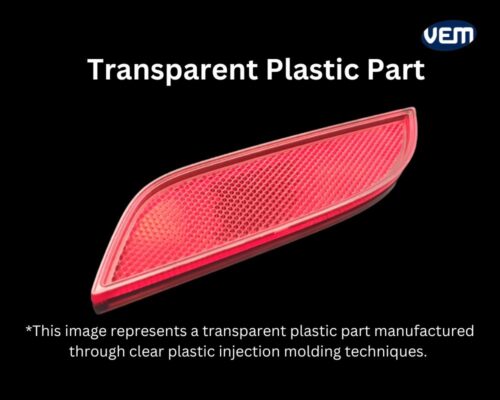

Clear plastic injection molding is more challenging than regular injection molding processes due to its high aesthetic requirements

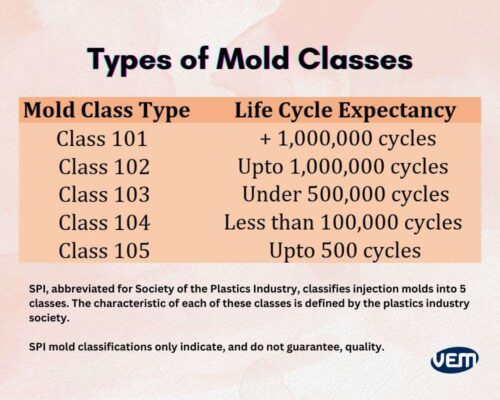

The lifespan of an injection mold is affected by various factors, such as steel material, plastic molding material, maintenance and many more.

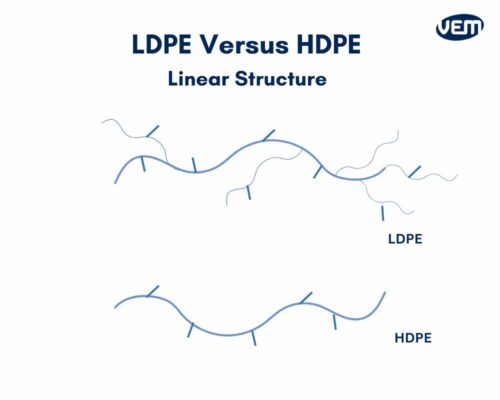

Polyethylene is one of the most popular plastic materials on the market. LDPE and HDPE are among the most used variantes of it.

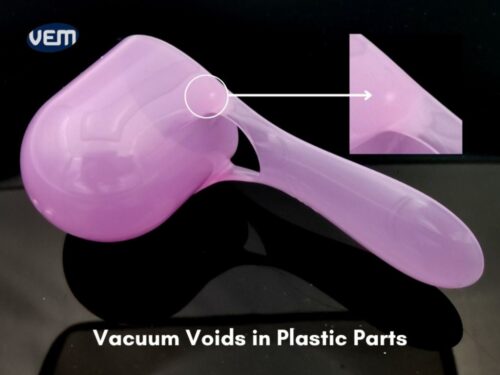

Vacuum voids are a type of injection molding defect that causes air-trapped bubbles in the plastic part.

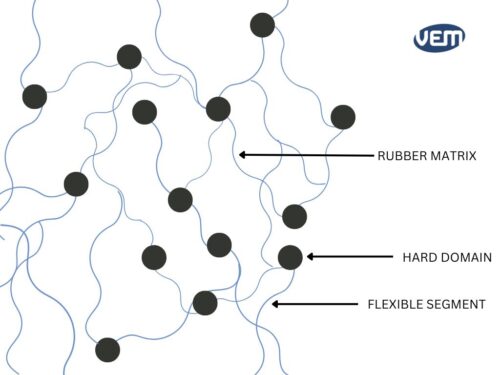

Thermoplastic Elastomers are flexible, rubber-like injection molding materials that process like plastic.

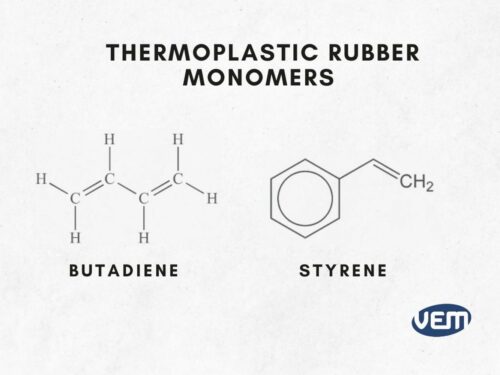

Thermoplastic Rubber (TPR) is a type of injection molding material that has a mix of both plastic and rubber-like properties.

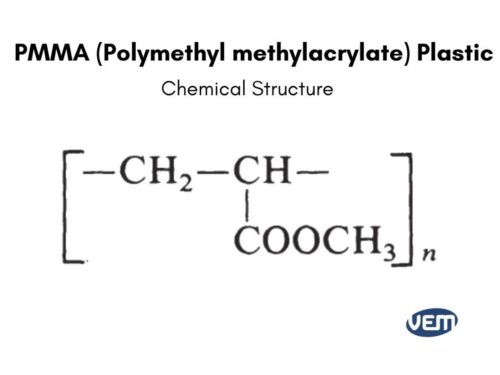

PMMA, also known as Acrylic has become a popular material choice among many different industries.

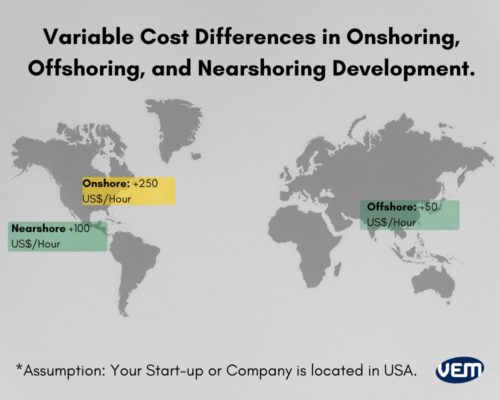

Offshoring, Nearshoring and Onshoring are often used and popular among manufacturing companies.

The medical device and component field has one of the strictest regulations. Which materials can be used for what kind of application?

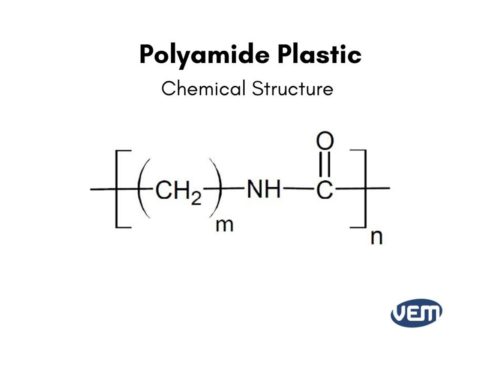

PA and Nylon are common and very popular plastic injection molding materials that come in various types and properties.

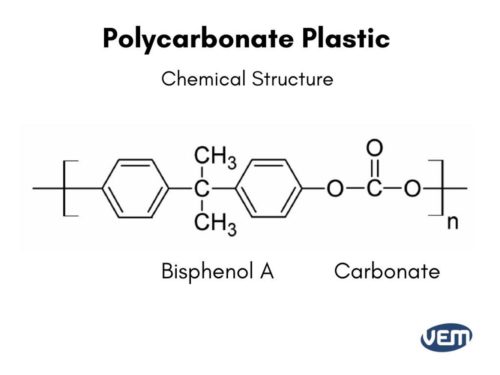

PC can be used in applications where other materials don't stand a chance, especially its transparency is highly sought after.

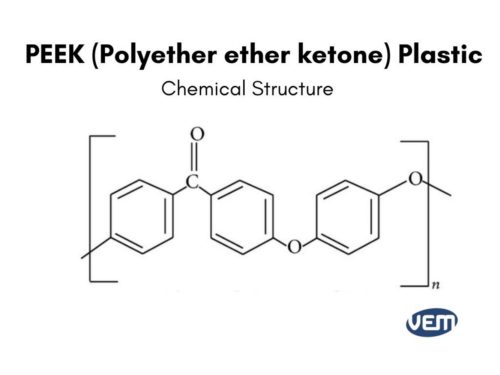

PEEK is a great choice of material when chemical resistance and resistance against thermal degradation is needed.

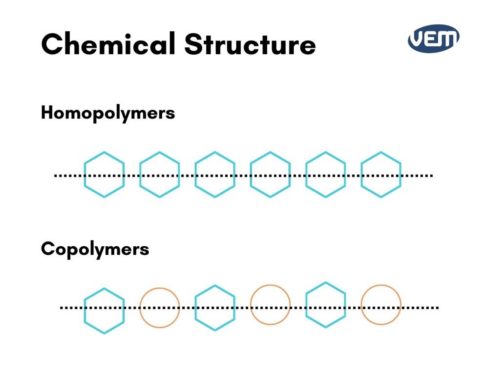

Homopolymers and Copolymers are the most common plastics that are used in various industries, but what are the differences in structure and application?

Successfully sourcing or manufacturing in India can be very rewarding for every company.

Have you ever wondered what is the difference between those and how to utilize it for your project?

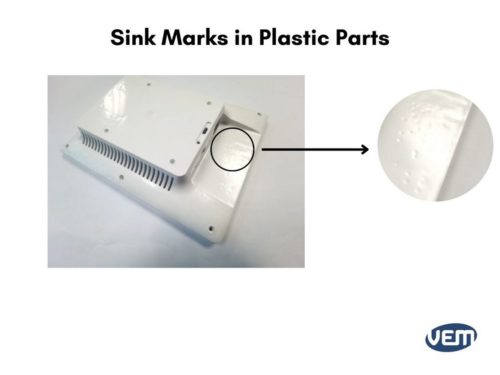

Sinks marks are a common problematic occurence during injection molding, but there are ways to avoid it.

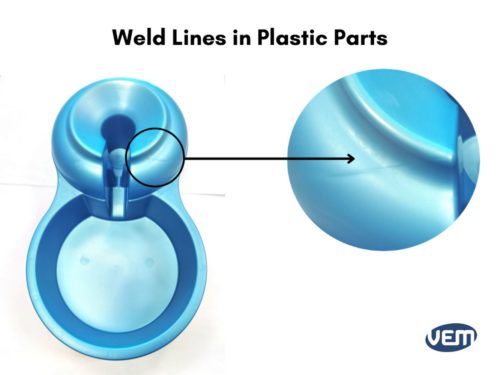

Weld lines can cause cosmetic or technical problems to a part. Take a look at the causes and solutions.

Clean room manufacturing and molding is a complicated topic, that is only for advances molders. Let's shine some light on it.

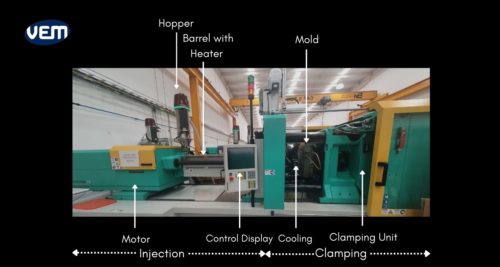

Do you want to use injection molding as your manufacturing solution? Then take a look.

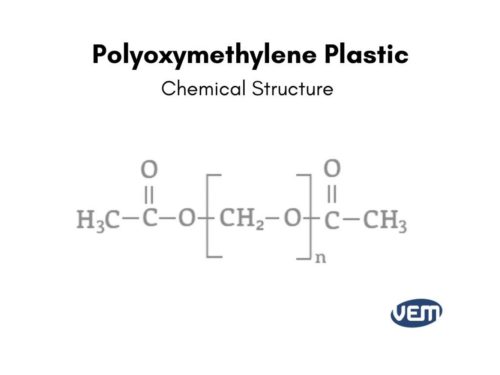

POM, an engineering thermoplastic has a wide range or applications with it's specific properties.

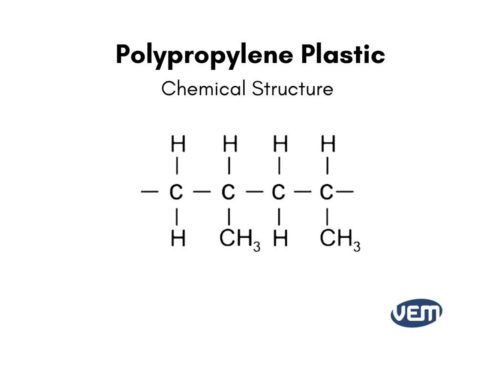

PP, Polypropylene is a common and often used material in plastic product, check out the details.

Mold defects are a common topic and especially plastic warpage can have a huge impact on the final part application.

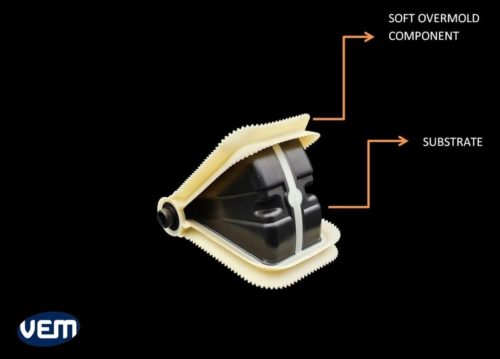

Overmolding and insert molding are common techniques in injection molding. All you need to know about those is here!

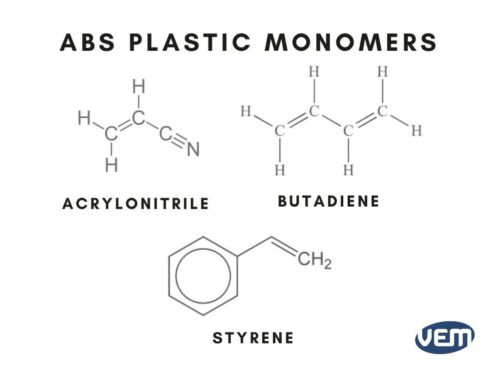

ABS is one of the most popular choices in Injection Molding, and there is a good reason for it.

Finding suppliers in Mexico can be tough, but rewarding. Learn how to go about manufacturing in Mexico with this End to End guide.

Die spotting is a process that improves quality and reduces costs when building molds, yet it is not often talked about.

3D steel printing can significantly lower cycle times in plastic manufacturing. Learn more about its process, quality, reliability and some real case examples.

Transferring your existing production into another country can be frightening. We have done it successfully and invite you to read about our journey.

The manufacturing scene in Thailand has been stable and popular for decades. Find out why we decided to have one of our main productions in Thailand.