3D Printed Inserts for Injection Molding

3D Steel printing is a laser-based technology that produces three-dimensional parts layer by layer from metal. The method relies on a digital data file transmitted to a machine that then builds the component. Metal additive manufacturing produces complex parts without the design constraints of traditional manufacturing methods.

Contents

3D steel printing in a nutshell

The most common 3d steel printing technology

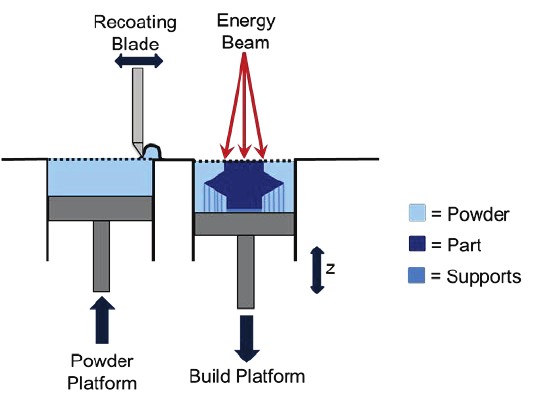

There are many different technologies for 3D printing. For 3D steel printing, however, the most commonly used one is powder bed processes. There are several abbreviations that roughly all describe a very similar process.

- SLM – Selective Laser Melting

- SLS – Selective Laser Sintering

- DMLM – Direct Metal Laser Melting

- DMLS – Direct Metal Laser Sintering

All of those belong to the ASTM standard term PBF, which stands for powder bed fusion.

Schematic of a powder bed fusion process. Brandon Lane, ResearchGate

Why do injection molders need 3D printing?

3D steel printing is already quite popular in the molding and mold-making industry. Just like in other industries, there is an undeniable advantage over traditional manufacturing, for specific projects.

In the molding industry, it is all about the cycle time during production. Since the beginning of injection molding as a way of producing plastics, mold makers have tried to reduce the cycle time as much as possible. To achieve this, you need to cool down the plastic part as much as possible after injection.

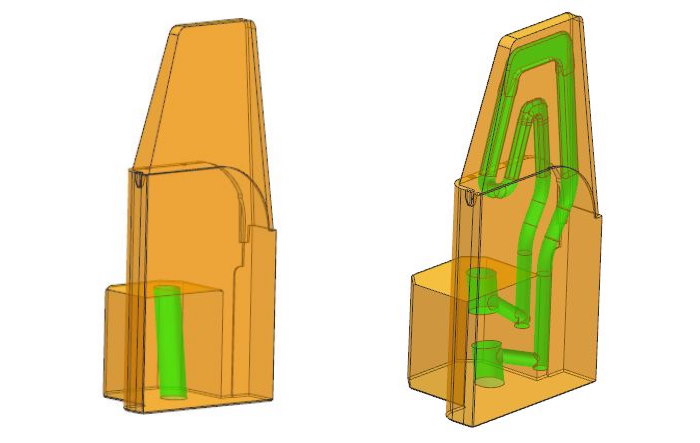

Conventional manufacturing however has a limitation when it comes to those cooling channels. Only straight lines can be drilled. There are many parts that have shapes that do not allow straight cooling lines to come close enough to the plastic surface. Those projects in particular benefit the greatest from 3D printing.

Left: regular cooling channels, Right: conformal cooling

With 3D printing, a manufacturer can print conformal cooling channels inside the inserts. These allow designing the shape along the plastic area of a part, which in return provides a much better cooling effect.

Knowing that cooling time is the largest contributor to cycle time, made conformal cooling channels increasingly popular.

At the same time, some parts require conformal cooling to avoid warpage when being molded. We have had plenty of projects where the only solution to mold good parts was using 3D printing to enable better cooling.

In addition to that, there are also part shapes that result in a lot of machining and scrap material when making mold inserts. With additive manufacturing, you can directly print the shape that you need and thus save material. Powder prices for 3D printing are constantly decreasing, which widens the areas of application within mold making.

3D steel printing in VEM Group

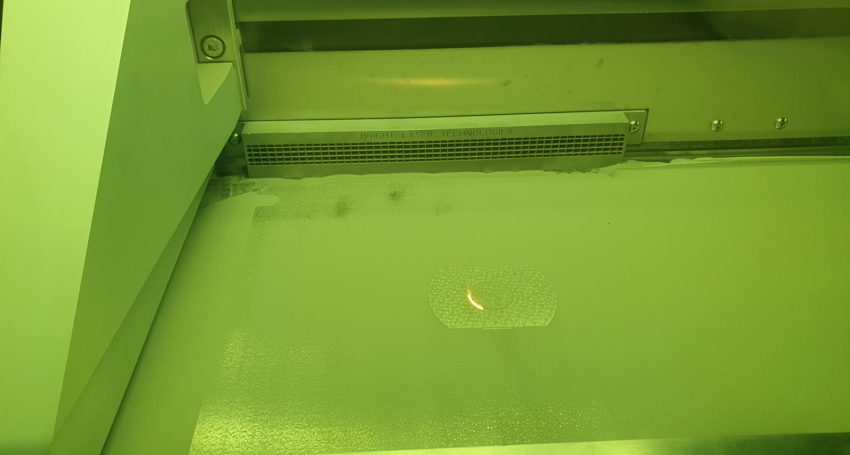

Laser melts steel powder to create an object layer by layer

Mold inserts with additive manufacturing

At the VEM Group 3D printing is nothing new. We have been utilizing this technology for many years already and have a large collection of documentation on finished projects. Be it reduced cycle time or sufficient cooling to avoid warpage issues, 3D printing has been a steady part of our portfolio.

Additionally, we receive more and more inquiries where customers want to achieve the lowest cycle time possible. Especially for mass production, the ROI can skyrocket.

Market demands for faster cycle time

Many of those reading this article are deeply involved in the plastics industry. Everybody knows it, everybody talks about it, the industry is changing. The demands are becoming increasingly more difficult to meet and product lifecycles, as well as time to market, are becoming shorter.

As a result, many customers ask us to use 3D printing technology in their molds, to give them an edge over their competition. The main factor for most of our customers is the savings potential during the production of plastic parts. Even a small percentage decrease in cycle time can result in huge savings.

Fortunately, 3D printing has become more affordable than it was a few years ago. Nowadays you pay a small premium to have conformal cooling channels in your mold. The ROI of doing so can be enormous.

BLT A320 dual head 3D printer

BLT printer at VEM

We have planned our investment in the right 3D printer for a long time. After testing almost every reputable manufacturer in the market, we decided on acquiring a 3D printer from BLT.

With our own printer in-house, we have better control over processes and quality control of printing. Furthermore, the price we can offer to our customers is very competitive. Combining lower prices with shorter a lead time gives in-house 3D printing a great advantage at VEM.

The BLT printer is equipped with a dual-head laser (2x 500W) and can print parts up to 250mm x 250mm x 300mm (10” x 10” x 12”). It represents the latest technology in the market with the latest lasers from IPG Germany.

Conformal cooling in molds – case study

3D printing a hot runner gate bushing

This part is from an internal case study. The goal is to apply conformal cooling to hot runner gate bushings in order to better control the mold. Using a hot runner has become almost standard to many molds that we are building. Combining the hot runner with better-cooled gate bushings, further improves the mold performance.

As seen in the picture, we designed conformal cooling channels close to the plastic area. There is no way to have those cooling channels with conventional methods, that deep into the bushing.

Conformal cooling channels, 3D model vs final print

Steel for 3D printing – Quality

There are some common misconceptions when it comes to printed metal. Many think that printed metal, from powder, cannot be as strong and durable as conventionally manufactured steel. However, it has been proven that there is no significant difference in the static properties such as tensile strength and stiffness. We have been working with 3D printed inserts for a long time now and can ensure you that the quality is sufficient.

We also got curious and wanted to take a look into the inner steel structure and surface of printed steel parts. Let’s take a look at our latest research.

Smoothly polished inserts

To look at the inner quality of the steel, we decide to fully print a hot runner gate bushing with conformal cooling. We use a fine machining finish on the whole part, with the help of our high-speed CNC milling machines. The surface is SPI B2.

After that, we polish the cap to achieve an A1 mirror finish. After a thorough inspection of the surface, we cannot find any issues. The surface is smooth, and its roughness satisfies the SPI A1 surface finish standard.

Mirror-polished head of the printed insert

Hardness check

The mold’s working hardness, achieved by heat treatment, affects properties such as compression strength, wear and corrosion resistance, and toughness. It plays a big role in resistance against wear, pressure, and indentation. Reduced hardness leads to a better toughness.

Most tool steels have high hardness requirements. Freshly printed inserts, before heat treatment, come out with around 34-36 HRC. After heat treatment, we can provide an HRC of 48-52. Most projects are within this hardness range.

3D printed insert cut open to inspect steel quality

Tool reliability

Our customers and partners have high expectations of our molds, especially those made with 3D printed inserts. They expect the highest quality for the lowest cost.

That is one of the reasons why we use printed inserts with conformal cooling. It significantly improves the rate of production while keeping the quality stable.

Another advantage is the elimination of supply chain issues when it comes to ordering steel. Normally, steel must be ordered in a variety of sizes to have as little waste and machining as possible. Thus, we order the steel once we know what is needed.

When it comes to printing, there is no such need. Steel powder can be printed into almost any shape, giving us the advantage of always having enough powder in stock.

The lifetime that we have experienced with 3D printed inserts, is the same as with conventionally machined inserts. With clean water flowing through the cooling channels and regular mold maintenance, you will be rewarded with higher production rates than your competitors.